- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/220V/380V

-

Power:

-

3KW/3.7W

-

Weight:

-

260 KG

-

Dimension(L*W*H):

-

1480*800*980mm/1940*980*1100mm

-

Product name:

-

Frozen meat dicing machine

-

Capacity:

-

500-600kg/h,700-900kg/h

-

Cutting groove size:

-

84x84x350mm

-

Material:

-

SUS304 Stainless Steel

-

Power source:

-

Electric

-

Certification:

-

ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL

-

Cutting grid size:

-

4, 5, 6, 7, 8, 9, 11, 13, 16, 20, 27 mm

-

OEM/ODM Service:

-

Acceptable

-

Color:

-

Silver

-

Function:

-

Dicing Slicing Frozen Meat

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Voltage:

-

110V/220V/380V

-

Power:

-

3KW/3.7W

-

Weight:

-

260 KG

-

Dimension(L*W*H):

-

1480*800*980mm/1940*980*1100mm

-

Product name:

-

Frozen meat dicing machine

-

Capacity:

-

500-600kg/h,700-900kg/h

-

Cutting groove size:

-

84x84x350mm

-

Material:

-

SUS304 Stainless Steel

-

Power source:

-

Electric

-

Certification:

-

ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL

-

Cutting grid size:

-

4, 5, 6, 7, 8, 9, 11, 13, 16, 20, 27 mm

-

OEM/ODM Service:

-

Acceptable

-

Color:

-

Silver

-

Function:

-

Dicing Slicing Frozen Meat

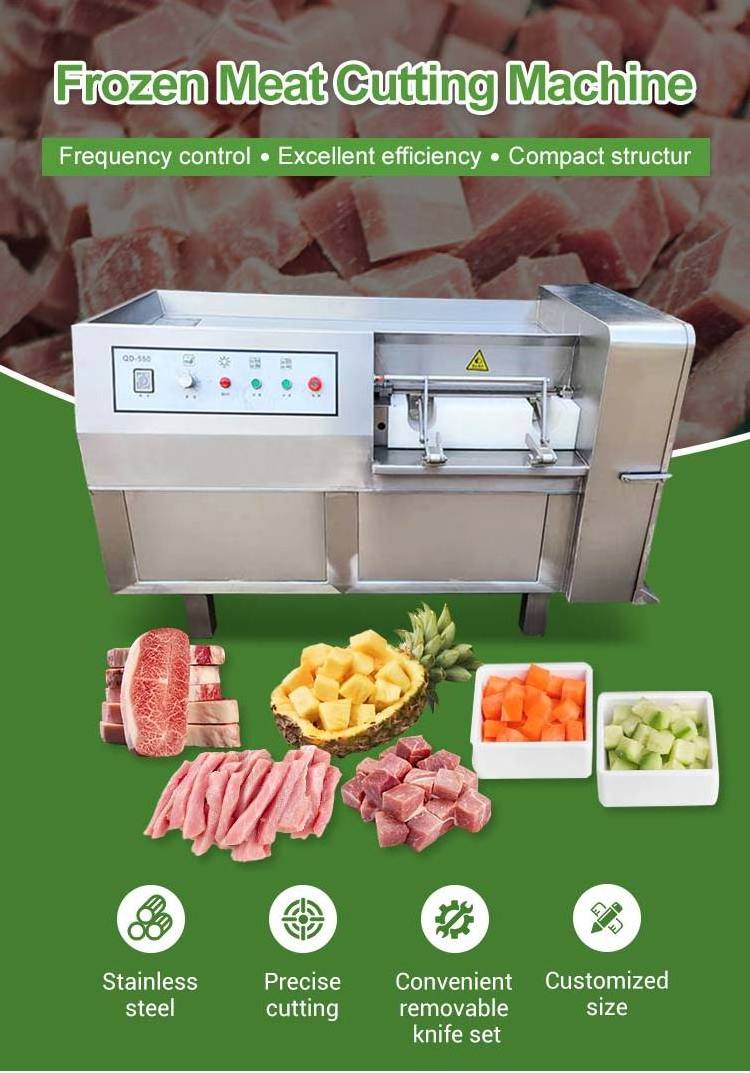

Introduction

Meet Cutting machine is an important equipment in the production process of meat products. Cut meat, fat and other main raw materials into diced meat required by users, and adjust the size of the knife grid to cut shredded meat, meat slices, and meat diced. The size of the diced meat is determined by the number of blades in the knife grid. The cutting machine is mainly composed of a frame, a reducer, a motor, a tool rest, an eccentric shaft assembly, a main cutter assembly, and a hydraulic system. The main motor drives the main shaft to rotate through the reducer, the fork on the main shaft drives the upper knife grid, the lower knife grid and the left and right reciprocating motion, the material pushed out by the push block is cut into strips, and the main cutter cuts the meat strips into diced meat.

Application

It is used for dicing of poultry products, various frozen meat trays and meat products. It is formed at one time. The cut products have clear edges and corners, regular shapes and consistent sizes.

This machine is often used in meat processing factories, snack food processing enterprises, Chinese restaurants, central kitchens, western restaurants, etc.

Features

1 . The safety protection performance is good, and the rotating cutter stops working immediately after the front door is opened.

2 . All kinds of knives are easy to disassemble, easy to install, easy to clean and replace the knife grid.

3 . The side pressure mechanism can increase the amount of meat cut at one time, and help the pre-pressure to reach the set value faster, improving production efficiency.

4 . The design of the fork mechanism improves the cutting quality of the product, reduces the noise, and reduces the mechanical failure rate.

5 . Adjust the pre-pressure knob to ensure consistent product throughout the cutting process.

6 . Meat material can be fed in steps to minimize product squeezing during cuttingdjust the pre-pressure knob to ensure consistent product throughout the cutting process.

7 . Changing the number of blades in the knife grid can cut meat of different sizes, which is easy to combin.

Paramater

|

Model |

Output |

Powder |

Oil pump motor power |

Main engine motor power |

Longest cutting length |

Cut grid size (mm) |

Cutting groove size |

weight |

Size |

|

GD-350 |

500-600kg |

3.2kw |

1.5kw |

1.7kw |

300mm |

5/6/7/8/9/11/13/16/20/27 (Can be customized) |

84*84*350mm |

500kg |

1480*800*980mm |

|

GD-550 |

700-900kg |

3.7kw |

1.5kw |

2.2kw |

550mm |

5/6/7/8/9/11/13/16/19 (Can be customized) |

120*120*550mm |

700kg |

1940*980*1100mm |

|

Note: Suitable for cutting boneless meat, not suitable for too hard bones, easy to damage the blade |

|||||||||

Q1. How does the machine adapt to our voltage?

For each device, our sales staff will confirm the voltage with the customer.

Q2. How can I buy this machine?

Our sales staff will discuss with you all the details of the machine, delivery date and payment terms.

Q3. How long is the warranty period of your machine?

One year after delivery. Within one year, if the problem is not caused by incorrect operation, we can provide damaged parts free of charge.

Q4. What can you provide for after-sales service?

If the customer needs, we can provide installation and operation instructions through video.

Q5. If we have very special requirements for the production line, can you help me with the design?

Provide customized design.

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.