Q: What material damper does your machine use?

A: Stainless steel double layer damper.

Stainless steel one without rusty. Two layers for moisturing much more efficiency.

Q:What material moisture bin does your machine use?

A: Stainless steel moisture bin, the maize can sleep,and the maize skin can absorb moisture to better remove the germ and bran.

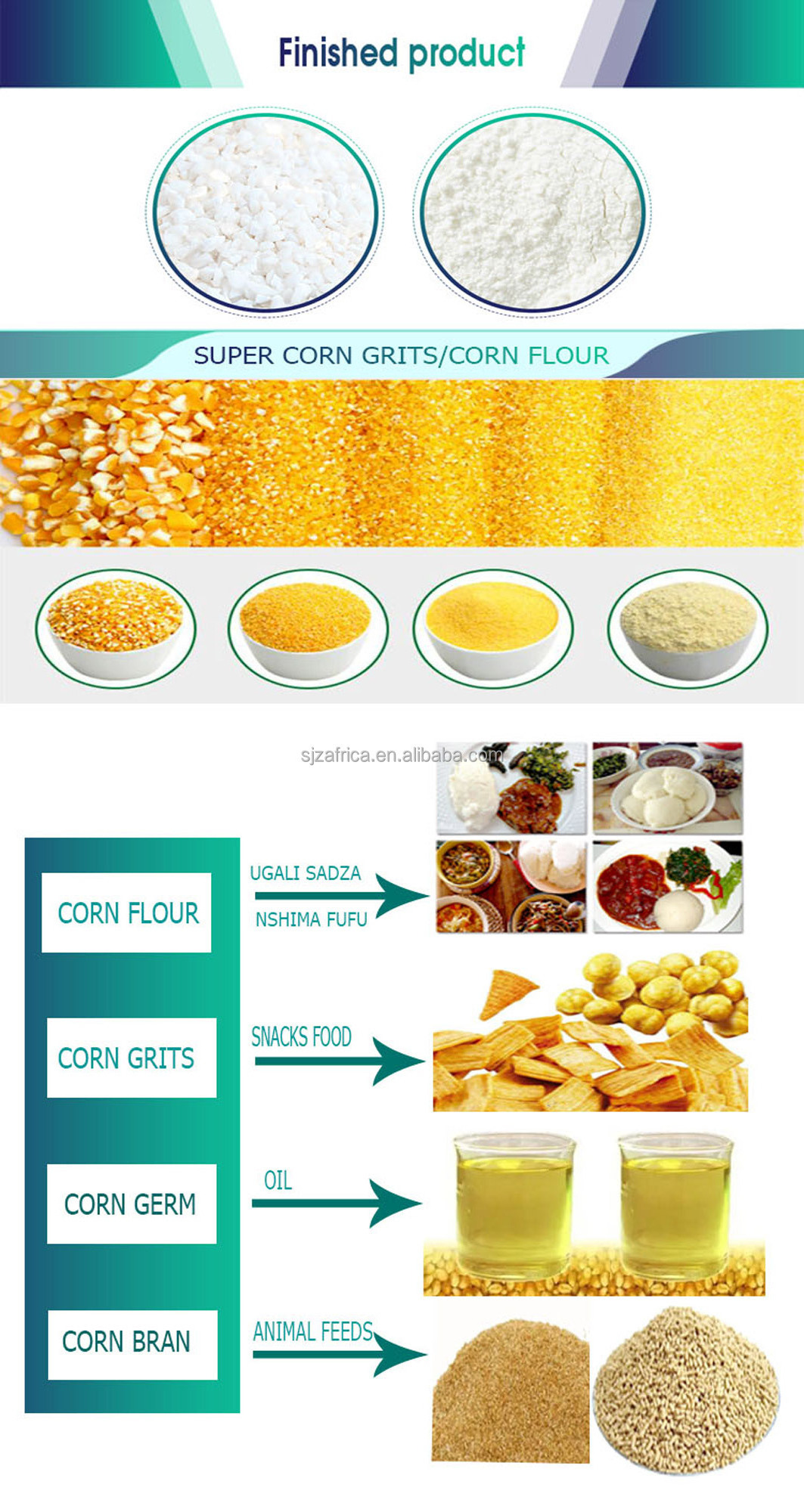

Q:Can I use this machine to produce different sizes maize flour?

A: Yes. In the sifter, we will give you different hole size of mesh screens, to get the different size of final products.

Q: Can the maize mill machine also process wheat?

No,it is because the maize and wheat Physical Characteristics is different,like the shape,the hardness, all are different,and the final product flour size is also different. The cleaner,the roller mill parameter, the plansifter sieve all are different. As professional manufacture for maize meal or flour,cannot process maize and wheat same time.

Q: Can an automatic packing machine be used to pack 1kg 2kg 5kg 10kg 20kg 25kg 50kg bags?

A: No, they need three kinds of automatic packing machine, like 1-5kg, 10-20kg and 25-50kg.

Q:Can you provide engineer to install the machine?

A: Yes. We can arrange Chinese engineer to go to your city to guide the installation and commissioning of machine.

Q:How will the machines be shipped to my country?

A: We put the machines into the containers, then the machines will be shipped to your country from Tianjin Port China by sea. And if you buy spare parts from our company, we will ship the spare parts by air.

Q: Do you have running machines in Africa? Can I visit?

A: Yes. In Africa we have branch offices in Kampala Uganda, Lusaka Zambia, Addis Ababa Ethiopia, our people can take you to visit our running machines. And in Kenya, Nigeria, South Africa, Zimbabwe, Rwanda, Tanzania, etc. We have many machines in running. If you want to visit, you can contact us.

Q: Where can I buy the spare parts after purchasing the machine from your company?

A: If you buy our machines, we can provide one year spare parts for free. Then if you need spare parts, you can buy them from our Uganda/Ethiopia/Zambia offices or our China company. They we will ship them by air, need about 6 working days will arrive to your city.

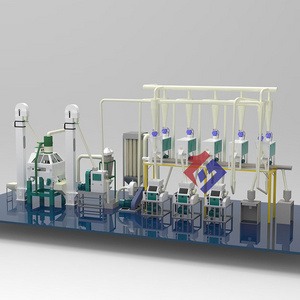

Q: Can you design the workshop for me?

A: Yes, our professional technical team can design the workshop according the capacity of machine and your need. Then can provide the drawing.