making it very selective. This type of bead also has advantages in crush strength, durability and high rate of adsorption. The 3A molecular sieve can remove moisture in both liquid and gas applications. Type 3A is used in the production of insulated glass, refrigerant drying, general moisture removal and the drying of natural gas, hydrocarbon liquids, ethanol and reactive monomers such as olefins.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

AlCaNaO9Si3

-

EINECS No.:

-

N/A

-

Place of Origin:

-

China

-

Brand Name:

-

Zhongchuang

-

Model Number:

-

ZC-MS112210

-

Bulk density(g/ml):

-

≥0.62

-

H2O capacity(%):

-

≥25

-

Model Number::

-

13x molecular sieve

-

Adsorbent Variety::

-

Molecular Sieve

-

Bulk density (g/cm3)::

-

≥0.63

-

Particle size of the qualified(%)::

-

≥99.00

-

Static CO2 adsorption::

-

≥18

Quick Details

-

CAS No.:

-

63231-69-6

-

Purity:

-

99%min, 99.9%

-

Other Names:

-

zeolite

-

MF:

-

AlCaNaO9Si3

-

EINECS No.:

-

N/A

-

Place of Origin:

-

China

-

Brand Name:

-

Zhongchuang

-

Model Number:

-

ZC-MS112210

-

Bulk density(g/ml):

-

≥0.62

-

H2O capacity(%):

-

≥25

-

Model Number::

-

13x molecular sieve

-

Adsorbent Variety::

-

Molecular Sieve

-

Bulk density (g/cm3)::

-

≥0.63

-

Particle size of the qualified(%)::

-

≥99.00

-

Static CO2 adsorption::

-

≥18

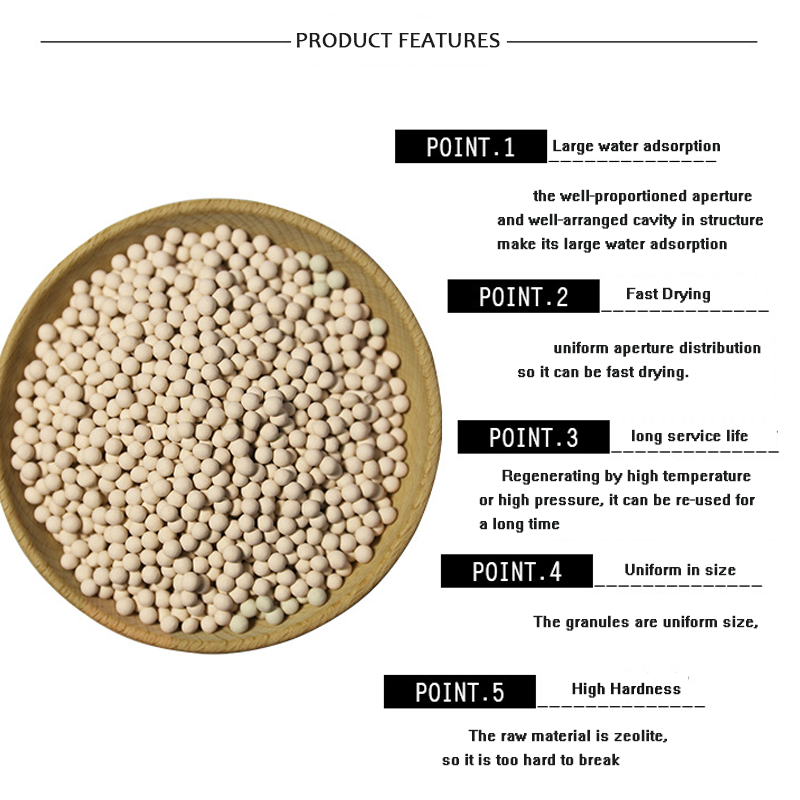

Product Description

Molecular sieve adsorbents are crystalline aluminosilicates, known as zeolites. Their unique structure allows the water of crystallization to be removed, leaving a porous crystalline structure. These pores, or cages, have a high affinity to re-adsorb water or other polar molecules. Aided by strong ionic forces (electrostatic fields) due to the presence of cations such as sodium, calcium and potassium, and by the enormous internal surface area of up to 1,000 m2/g, molecular sieves will adsorb a considerable amount of water or other fluids. If the fluid to be adsorbed is a polar compound, it can be adsorbed with high loading, even at very low concentrations of the fluid. Molecular sieves will, therefore, remove gas or liquid impurities to very low levels (ppm or less).

Another feature of molecular sieve adsorbents is their ability to separate gases or liquids by molecular size or polarity. The pore, or cage, openings are the same size as many molecules, e.g., in the case of hydrocarbon paraffins, straight-chained molecules can fit into the pores and be adsorbed, while the branched-chain molecules cannot enter the pores and pass through the molecular sieve bed unadsorbed.

|

U13X Molecular Sieve

|

unit

|

sphere

|

|

pallet/cylindrical

|

|

||

|

Diameter

|

mesh

|

8X12

|

4-12

|

8X12

|

1/8

|

||

|

water adsorption capacity

|

>%wt

|

26

|

26

|

26

|

26

|

||

|

Co2 ADSORPTION CAPACITY

|

<mg/g

|

180

|

180

|

180

|

180

|

||

|

bulk density

|

>g/ml

|

0.65

|

0.64

|

0.62

|

0.61

|

||

|

strength

|

>N

|

30

|

70

|

30

|

70

|

||

|

Abrasion

|

<%et

|

0.1

|

0.1

|

0.2

|

0.2

|

||

|

water content

|

<%wt

|

1.5

|

1.5

|

1.5

|

1.5

|

||

Molecular Sieve Series

3A Molecular Sieve

The 3A molecular sieve is an alkali metal aluminosilicate with a pore opening of approximately 3 angstroms. Type 3A is made by ion-exchanging the sodium in the type 4A sieve with potassium. The 3A molecular sieve will exclude most molecules except water,

making it very selective. This type of bead also has advantages in crush strength, durability and high rate of adsorption. The 3A molecular sieve can remove moisture in both liquid and gas applications. Type 3A is used in the production of insulated glass, refrigerant drying, general moisture removal and the drying of natural gas, hydrocarbon liquids, ethanol and reactive monomers such as olefins.

making it very selective. This type of bead also has advantages in crush strength, durability and high rate of adsorption. The 3A molecular sieve can remove moisture in both liquid and gas applications. Type 3A is used in the production of insulated glass, refrigerant drying, general moisture removal and the drying of natural gas, hydrocarbon liquids, ethanol and reactive monomers such as olefins.

4A Molecular Sieve

The 4A molecular sieve is an alkali metal aluminosilicate with an effective pore opening of approximately 4 angstroms.

The sodium form of type A is widely used as a general-purpose drying agent and has good physical and adsorption properties.

Type 4A beads can be used to adsorb water, ammonia, methanol, ethanol and carbon dioxide. This type of molecular sieve is often used to remove moisture from gas and liquid streams, where co-adsorption of sulfur compounds and carbon dioxide is not a concern.

5A Molecular Sieve

The 5A molecular sieve is an alkali metal aluminosilicate with an effective pore opening of 5 angstroms and is the calcium-exchanged form of the type A zeolite. The strong ionic forces of the divalent calcium cation make 5A an excellent choice for removing carbon dioxide, carbon monoxide, alcohols and other oxygenates, hydrogen sulfide, methyl and ethyl mercaptans, and other polar molecules. This product is also effective for the bulk separation of normal and iso-paraffin hydrocarbons. This type of molecular sieve has a high rate of adsorption and desorption, a higher rate of contamination resistance and a high crush strength.

13X Molecular Sieve

The 13X molecular sieve is the sodium form of zeolite X and has a much larger pore opening than the type A crystals, with an effective pore diameter of 10 angstroms. It also has the highest theoretical capacity of the common adsorbents and excellent mass transfer rates. Type 13X offers enhanced adsorption performance over the type A zeolite, and it can remove impurities too large to fit into the type A zeolite crystal cages. It is also often used to separate nitrogen from the air to produce a high-purity oxygen stream. Our 13X materials are physically robust and have high adsorption capacity for water, alcohols and other oxygenates, sulfur

compounds and carbon dioxide.

compounds and carbon dioxide.

Application

Natural Gas Processing

Natural Gas Processing

Natural Gas Processing

Dehydration of natural gas and natural gas liquids such as propane and butane

Removal of CO2 , H2 S, mercaptans and other impurities from natural gas or natural gas liquids

Hydrogen Production or Recovery

Hydrogen Production or Recovery

Drying and purification of H2 using either thermal swing or pressure swing adsorption

Industrial Gases

Dehydration and CO2 removal from air for cryogenic processing

Separation of high-purity oxygen from air via Pressure Swing Adsorption (PSA) or Vacuum Swing Adsorption (VSA)

Recovery of inert gases by adsorption

Petroleum Refining

Dehydration of light-ends (e.g. olefin) for cryogenic recovery

Purification of feed to catalytic processes such as isomerization, dimerization and alkylation units

Chemical Storage

Underground cavern drying and treating

Storage tank breathers

Product recovery from vent streams

Fuel Ethanol Production

Bulk water removal at the azeotrope

Purification of food- and pharmaceutical-grade ethanol

Basic Petrochemical and Synthesis Gas Processes

Purification of natural gas feed

Drying and purification of the reformer gas prior to the ammonia loop

Treating of ammonia off-gas streams

Olefin and polyolefin production

Drying of cracked olefin gas, ethylene and propylene products

Dehydration and purification of ethane feed to the cracker

Impurity removal from polyolefin plant feed (catalyst protection from oxygenates, sulfides

Miscellaneous Petrochemicals

Drying of solvents

Purification of feed streams to catalytic processes such as for ethyl benzene

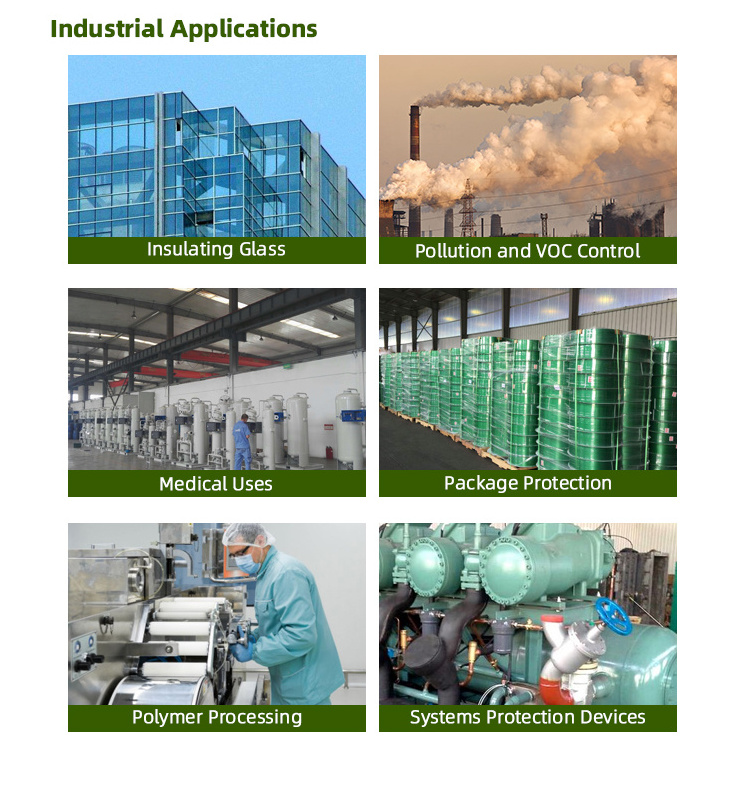

Industrial Applications

Insulating Glass

Prevention of condensation in the insulating glass space of windows

Pollution and VOC Control

Containment and concentration of solvent vapors

Medical Uses

Oxygen concentrators for respiratory therapy

Package Protection

Dehydration and trace contamination removal in enclosed spaces

Removal of odors

Polymer Processing

Removal of water of reaction in urethane formulations

Cell size control in blown foams

Plastic pellet driers prior to blowor injection-molding

Systems Protection Devices

Dehydration and filtration of refrigerant loops

Dehydration and purification of compressed breathing air

Dehydration of compressed air for pneumatic tools

Truck and railroad air brake drier

Product packaging

Hot Searches