- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Bathroom

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHENGYUAN

-

Model Number:

-

SY-03

-

Type:

-

PP PE MEMBRANE

-

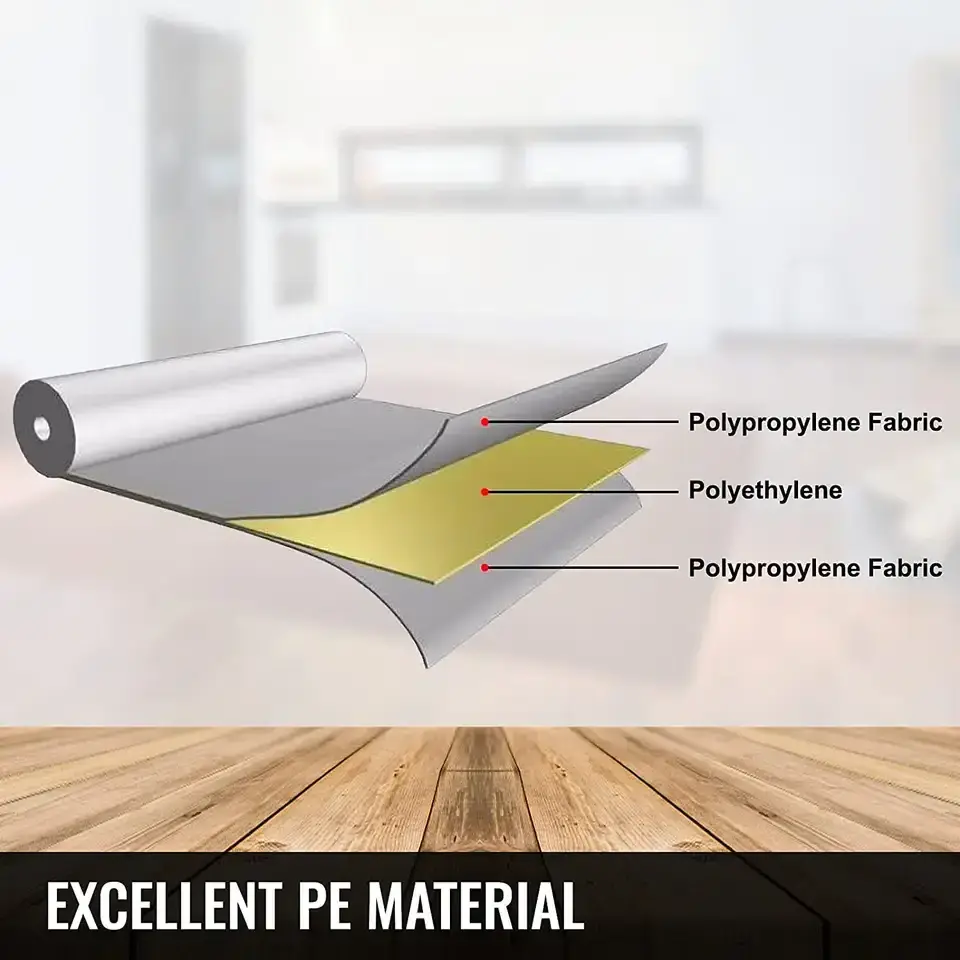

Material:

-

PP PE

-

Core Material:

-

POLYETHYLENE

-

Product Name:

-

POLYETHYLENE POLYPROPYLENE COMPOUND WATERPROOF MEMBRANE

-

MATERIAL:

-

Polypropylene non-woven fabric laminated with PE film

-

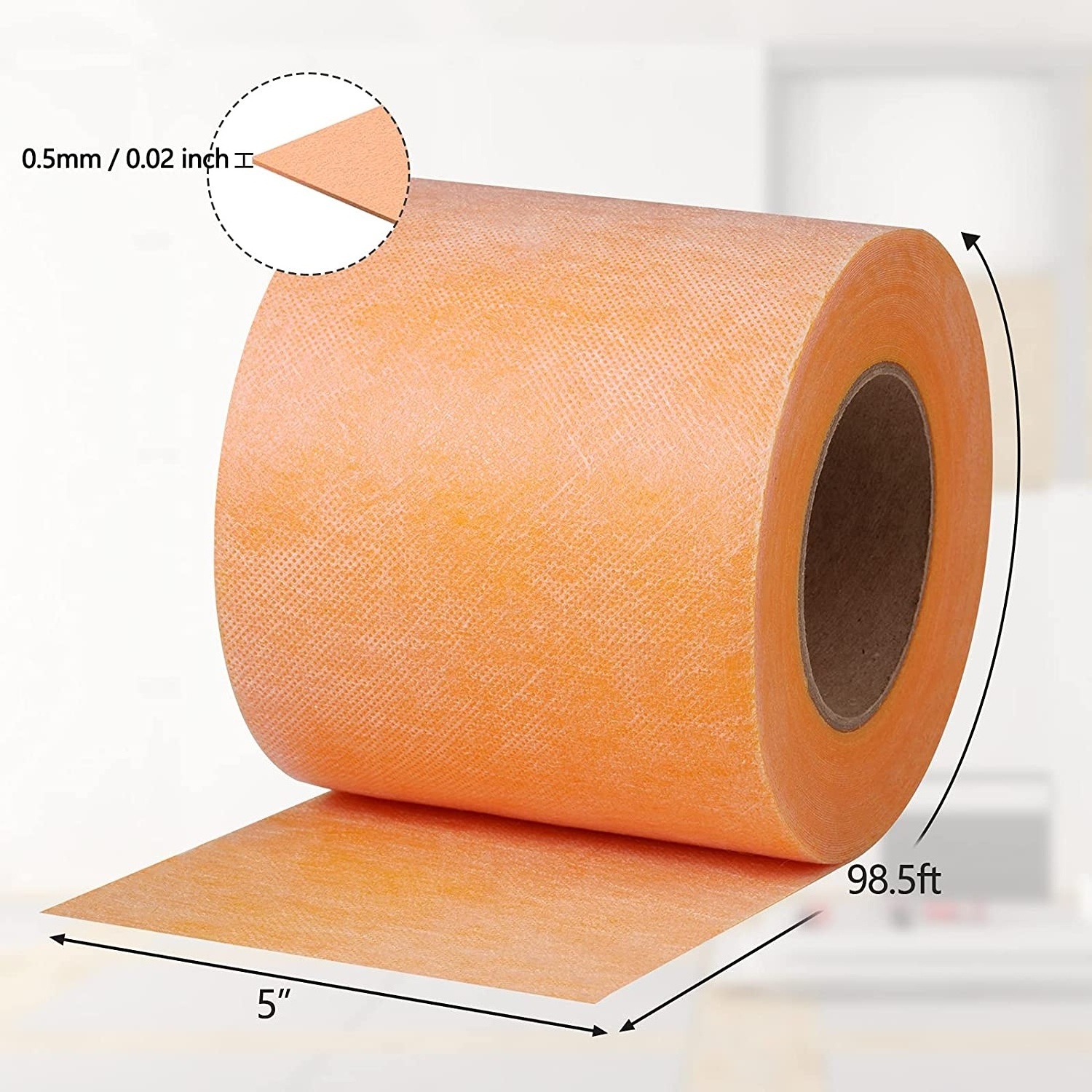

WIDTH:

-

50MM-1500MM

-

LENGTH:

-

30M 50M 80M 100M OR CUSTOMIZED

-

GRAMMAGE:

-

200G/M2 250G/M2 300G/M2 400G/M2 ...OR CUSTOMIZED

-

THICKNESS:

-

0.2MM 0.3MM0.4MM0.5MM...OR CUSTOMIZED

-

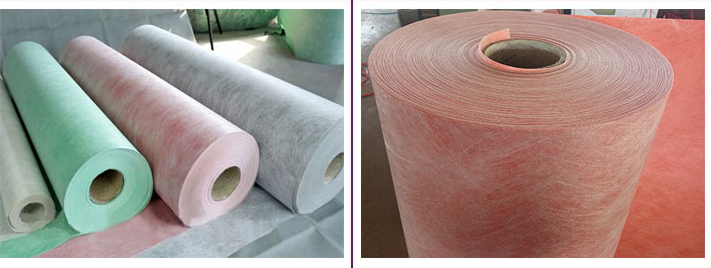

COLOR:

-

GREY WHITE GREEN BLACK RED BLUE OR CUSTOMIZED

-

PACKING:

-

Woven bags or as your requirement

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Bathroom

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHENGYUAN

-

Model Number:

-

SY-03

-

Type:

-

PP PE MEMBRANE

-

Material:

-

PP PE

-

Core Material:

-

POLYETHYLENE

-

Product Name:

-

POLYETHYLENE POLYPROPYLENE COMPOUND WATERPROOF MEMBRANE

-

MATERIAL:

-

Polypropylene non-woven fabric laminated with PE film

-

WIDTH:

-

50MM-1500MM

-

LENGTH:

-

30M 50M 80M 100M OR CUSTOMIZED

-

GRAMMAGE:

-

200G/M2 250G/M2 300G/M2 400G/M2 ...OR CUSTOMIZED

-

THICKNESS:

-

0.2MM 0.3MM0.4MM0.5MM...OR CUSTOMIZED

-

COLOR:

-

GREY WHITE GREEN BLACK RED BLUE OR CUSTOMIZED

-

PACKING:

-

Woven bags or as your requirement

Product Description

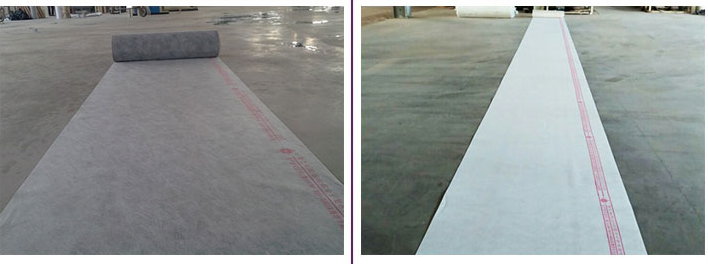

PE/PP Waterproofing Membrane

PE/PP Waterproofing Membrane is composed of polyethylene, high-strength (propylene/polyester) non-woven fabric, ultraviolet light-shielding agent, anti-aging agent and other macromolecule raw materials with the changes of their physical and chemical characters, and produced by automatic and single extrusion molding processing production line. The surface of the membrane are reinforced adhesive layers, and the middle of the membrane is composed of a waterproof layer and an anti-aging layer.

Specification

|

Product Name

|

Polyethylene polypropylene fiber composite waterproof membrane

|

|

Material

|

Polypropylene non-woven fabric laminated with PE film

|

|

Grammage

|

100g -1000g

|

|

Width

|

10cm 20cm 30cm 60cm 1.0m, 1.2m, 1.5m or as your requirement

|

|

Length

|

50m/roll, 100m/roll or as your requirement

|

|

Color

|

White, Grey, Green, Red, Black or Customized

|

|

Packing

|

Woven bags or as your requirement

|

Technical Datas

GB18173.1-2012-China Official Standard

|

ITEM

|

|

Index

|

||

|

|

|

FS2

|

||

|

Tensile strength N/cm

|

Normal temperature (23℃)

|

≥60 N/cm

|

||

|

|

High temperature (60℃)

|

≥30 N/cm

|

||

|

Elongation at break %

|

Normal temperature (23℃)

|

≥400%

|

||

|

|

Low temperature (-20℃)

|

≥300%

|

||

|

Tear strength (N)

|

|

≥50N

|

||

|

Watertightness (0.3Mpa) 30min

|

|

No leakage

|

||

|

Fold-ability at low temperature(℃)

|

|

-20℃ No cracks

|

||

|

extension and shrinkage after heating (mm)

|

Extension ≤

|

≤ 2 mm

|

||

|

|

Shrinkage ≤

|

≤ 4 mm

|

||

|

Hot air aging (80℃x168h)

|

Conservation rate of tensile breaking strength (%) ≥

|

80%

|

||

|

|

Conservation rate of elongation at break (%) ≥

|

70%

|

||

|

Alkali resistance (CaOH2saturated solution, normal temperature,168h)

|

Conservation rate of tensile breaking strength (%) ≥

|

80%

|

||

|

|

Conservation rate of elongation at break (%) ≥

|

80%

|

||

|

Artificial weathering aging

|

Conservation rate of tensile breaking strength (%) ≥

|

80%

|

||

|

|

Conservation rate of elongation at break (%) ≥

|

70%

|

||

|

Peel strength of the bonding(polypropylene fabric and polyethylene film)

|

(N/mm)(standard test condition) ≥

|

1.5N/cm

|

||

|

|

conservation rate of Soaking (normal temperature x168h)

|

≥70%

|

||

|

Combined strength (FS2 surface layer and core layer) (N/mm)

|

|

0.8 MPa

|

||

|

Note: If the membrane thickness is less than 1.0mm, the elongation rate at break shall not be less than 50% and the performance

data of other properties shall be over 80% of the test requirement. |

|

|

||

PRODUCT FEATHER

1. Anti-aging, anti-oxidation, anti-corrosion, good flexibility, easy bending without break, tensile and puncture resistance, good performance to block plant root thorn.

2. No cracks with the temperature of -40°C and no deformation with temperature of +100°C.

3. Environmental friendly, non-toxic, odorless and non-polluting which meet the requirements and standard of protective materials for drinking water distribution.

4. Excellent suitability and high efficiency for construction. It can be constructed on wet base without water or after the rain thus can save time and labor with good waterproof effect.

5. Strong waterproof performance. The polyhedral cement adhesive agent (special adhesive powder) used in conjunction with the membranes not only has adhesive properties which can seal the base, and block water, but also can keep water tightness and level the layer.

2. No cracks with the temperature of -40°C and no deformation with temperature of +100°C.

3. Environmental friendly, non-toxic, odorless and non-polluting which meet the requirements and standard of protective materials for drinking water distribution.

4. Excellent suitability and high efficiency for construction. It can be constructed on wet base without water or after the rain thus can save time and labor with good waterproof effect.

5. Strong waterproof performance. The polyhedral cement adhesive agent (special adhesive powder) used in conjunction with the membranes not only has adhesive properties which can seal the base, and block water, but also can keep water tightness and level the layer.

Application Scope

Polyethylene (propylene/polyester) waterproof membrane is widely used in various types of industrial, civil construction roofing,basement, kitchen and toilet, storage tanks, water conservancy, dams, mines, tunnels, bridges as well as culverts, subways,metallurgical and chemical project for impervious, moisture-proof and waterproofing.

Transportation & Storage

1. The packing should be kept intact and free from damage during storage and normal warranty is one year without damage.

2. The storage height must not exceed five packaging membranes heights and be placed on a ventilated, cool, and dry horizontal

floor.

3. No contact with acids, alkalis, oils, organic solvents, etc.

2. The storage height must not exceed five packaging membranes heights and be placed on a ventilated, cool, and dry horizontal

floor.

3. No contact with acids, alkalis, oils, organic solvents, etc.

MACHINES

.

Packing & Delivery

FAQ

Hot Searches