- Product Details

- {{item.text}}

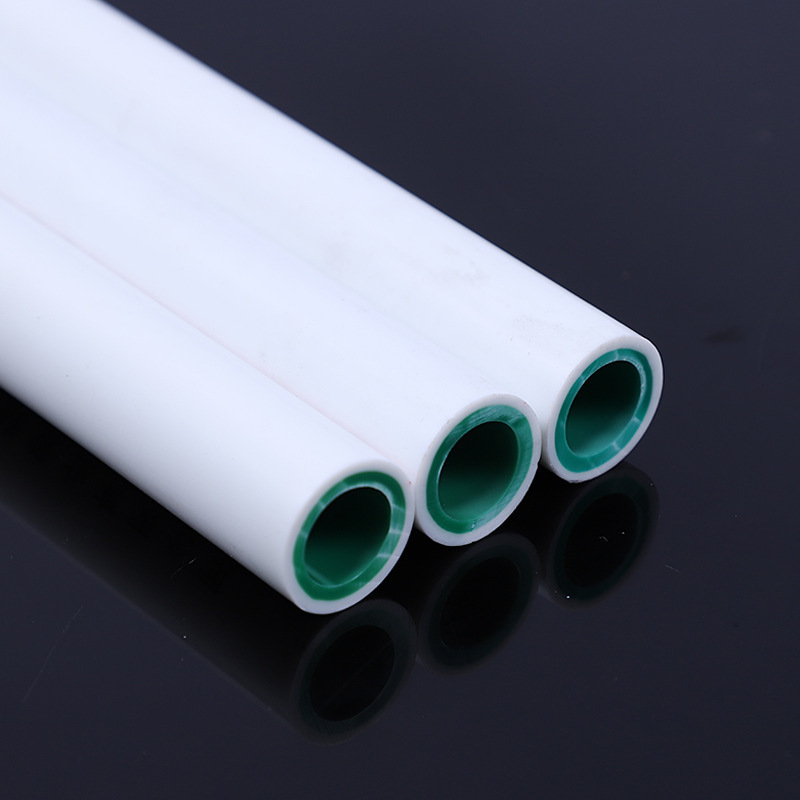

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HAISHA

-

Model Number:

-

dn20/25/32

-

Color:

-

White/Black/Grey

-

Application:

-

drainage system

-

Product name:

-

Union

-

Size:

-

20/25/32

-

Certification:

-

ISO

-

Material:

-

PPR

-

MOQ:

-

50Pieces

-

Advantage:

-

High Quaity

-

Lifespan:

-

50 Years Underground

-

Feature:

-

Corrosion Resistant

Quick Details

-

Technics:

-

Fusion

-

Shape:

-

Equal

-

Head Code:

-

Round

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HAISHA

-

Model Number:

-

dn20/25/32

-

Color:

-

White/Black/Grey

-

Application:

-

drainage system

-

Product name:

-

Union

-

Size:

-

20/25/32

-

Certification:

-

ISO

-

Material:

-

PPR

-

MOQ:

-

50Pieces

-

Advantage:

-

High Quaity

-

Lifespan:

-

50 Years Underground

-

Feature:

-

Corrosion Resistant

Products Description

Specification

PPR pipe sizes are from DN20 to DN110, mainly for domestic use.

The pressure grade has 1.25MPa, 1.6MPa, 2.0MPa, 2.5MPa, according to different thickness.

The pressure grade has 1.25MPa, 1.6MPa, 2.0MPa, 2.5MPa, according to different thickness.

|

PPR Pipe Series

|

|

|

|

|

||||

|

Standard

|

S5

|

S4

|

S3.2

|

S2.5

|

||||

|

Nominal Pressure/MPa

|

1.25

|

1.6

|

2.0

|

2.5

|

||||

|

DN/MM

|

THICKNESS

|

THICKNESS

|

THICKNESS

|

THICKNESS

|

||||

|

20

|

2

|

2.3

|

2.8

|

3.4

|

||||

|

25

|

2.3

|

2.8

|

3.5

|

4.2

|

||||

|

32

|

2.9

|

3.6

|

4.4

|

5.4

|

||||

|

40

|

3.7

|

4.5

|

5.5

|

6.7

|

||||

|

50

|

4.6

|

5.6

|

6.9

|

8.3

|

||||

|

63

|

5.8

|

7.1

|

8.6

|

10.5

|

||||

|

75

|

6.8

|

8.4

|

10.3

|

|

||||

|

90

|

8.2

|

10.1

|

12.3

|

|

||||

|

110

|

10

|

12.3

|

15.1

|

|

||||

Features.

1. High temperature resistance: PPR pipes can withstand high temperatures, making them suitable for hot water systems in households.

2. Corrosion resistance: PPR pipes are resistant to corrosion, ensuring a longer lifespan and minimal maintenance.

3. Smooth inner surface: The smooth inner surface of PPR pipes reduces friction and prevents the build-up of scale, ensuring efficient water flow.

4. Easy installation: PPR pipes are lightweight and easy to install, saving time and labor costs during the installation process.

5. Long lifespan: PPR pipes have a long service life, making them a cost-effective choice for household plumbing systems.

6. Environmentally friendly: PPR pipes are recyclable and do not release harmful substances, making them an environmentally friendly option for household plumbing.

7. Leak-proof: PPR pipes are joined using heat fusion, creating seamless connections that are resistant to leaks.

8. Low maintenance: PPR pipes require minimal maintenance and are less prone to clogging compared to other types of pipes.

2. Corrosion resistance: PPR pipes are resistant to corrosion, ensuring a longer lifespan and minimal maintenance.

3. Smooth inner surface: The smooth inner surface of PPR pipes reduces friction and prevents the build-up of scale, ensuring efficient water flow.

4. Easy installation: PPR pipes are lightweight and easy to install, saving time and labor costs during the installation process.

5. Long lifespan: PPR pipes have a long service life, making them a cost-effective choice for household plumbing systems.

6. Environmentally friendly: PPR pipes are recyclable and do not release harmful substances, making them an environmentally friendly option for household plumbing.

7. Leak-proof: PPR pipes are joined using heat fusion, creating seamless connections that are resistant to leaks.

8. Low maintenance: PPR pipes require minimal maintenance and are less prone to clogging compared to other types of pipes.

Application of PPR Pipe

PPR pipes are widely used in various applications, especially in household and commercial plumbing systems. They are commonly utilized for hot and cold water supply, as well as in heating systems such as underfloor heating. PPR pipes are also suitable for use in industrial applications, water treatment plants, and in the transportation of chemicals and compressed air. Their high temperature resistance, corrosion resistance, and smooth inner surface make them an ideal choice for a wide range of applications. Additionally, PPR pipes are often used in the construction of water supply networks and in irrigation systems due to their durability and long lifespan.

Manufacturing Technique

Brief description of the production process:

The production process of PPR pipes involves several steps.

1. Raw material preparation: The process begins with the selection and preparation of high-quality raw materials, such as

polypropylene random copolymer (PPR), which is a thermoplastic material known for its excellent properties such as high

temperature resistance and durability.

2. Extrusion: The raw materials are then melted and extruded through a die to form the desired shape and size of the PPR pipes. This extrusion process ensures that the pipes have a uniform structure and smooth surface.

3. Cooling and sizing: After extrusion, the pipes are rapidly cooled to solidify the material and then passed through a sizing sleeve to give them the correct dimensions and shape.

4. Cutting and packaging: The pipes are then cut into specific lengths and undergo quality control checks to ensure they meet the required standards. Once approved, the pipes are packaged and prepared for distribution.

Throughout the production process, strict quality control measures are implemented to ensure that the PPR pipes meet the necessary standards for strength, durability, and performance. This meticulous production process results in high-quality PPR pipes that are suitable for a wide range of applications in plumbing, heating, and industrial systems.

1. Raw material preparation: The process begins with the selection and preparation of high-quality raw materials, such as

polypropylene random copolymer (PPR), which is a thermoplastic material known for its excellent properties such as high

temperature resistance and durability.

2. Extrusion: The raw materials are then melted and extruded through a die to form the desired shape and size of the PPR pipes. This extrusion process ensures that the pipes have a uniform structure and smooth surface.

3. Cooling and sizing: After extrusion, the pipes are rapidly cooled to solidify the material and then passed through a sizing sleeve to give them the correct dimensions and shape.

4. Cutting and packaging: The pipes are then cut into specific lengths and undergo quality control checks to ensure they meet the required standards. Once approved, the pipes are packaged and prepared for distribution.

Throughout the production process, strict quality control measures are implemented to ensure that the PPR pipes meet the necessary standards for strength, durability, and performance. This meticulous production process results in high-quality PPR pipes that are suitable for a wide range of applications in plumbing, heating, and industrial systems.

Details Images

Hot Searches