- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

INNOVACERA

-

Dimension(L*W*H):

-

OD10.5*ID6.5*L78 mm

-

Weight:

-

0.3 KG

-

Working Temperature Range:

-

-50 - 1100 ℃

-

Core Components:

-

MCH

-

Color:

-

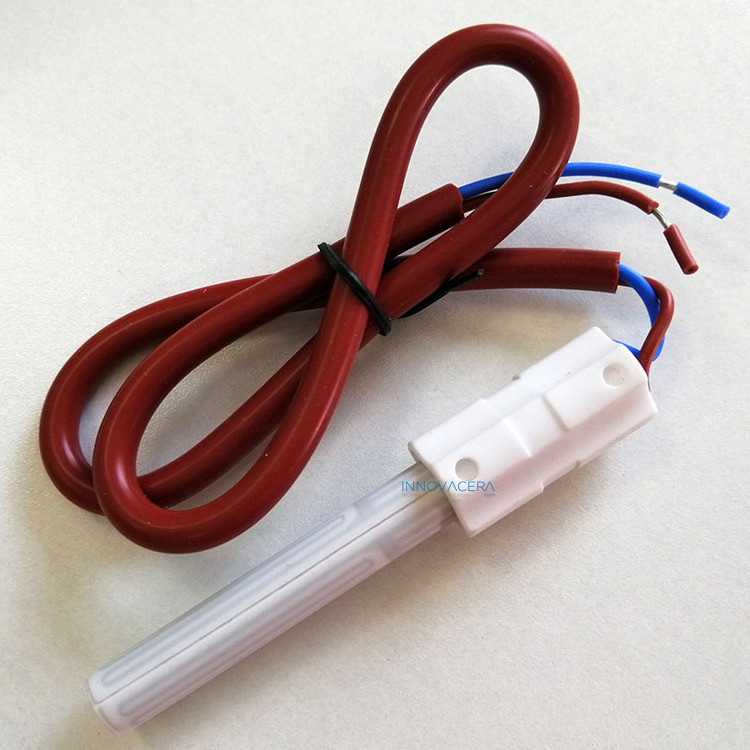

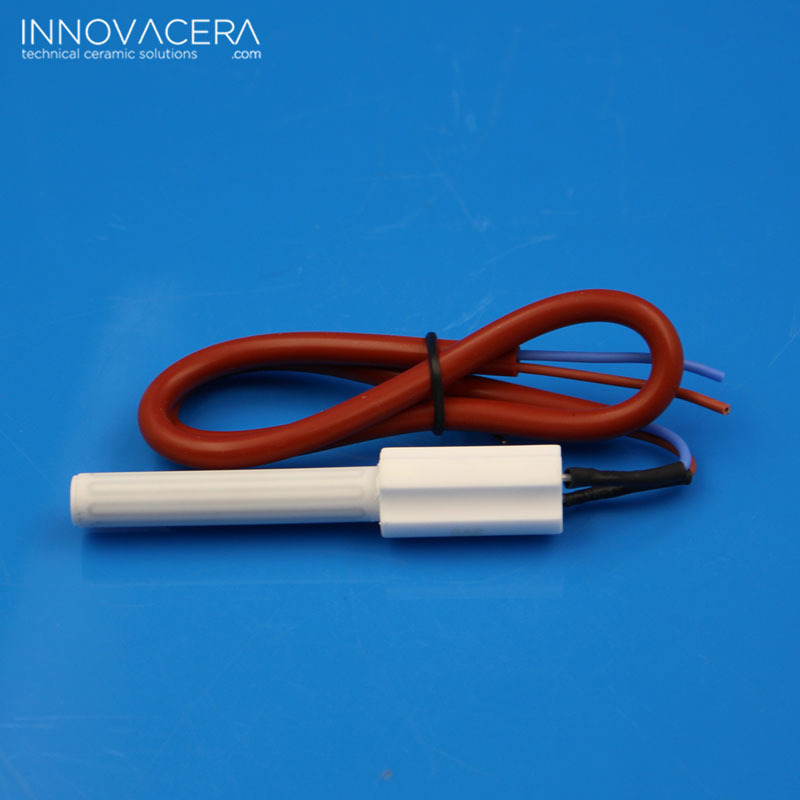

White

-

Density:

-

3.7g/cm3

-

Power:

-

150-255W

-

Thermal Conductivity:

-

25W/(m.k)

-

Wire:

-

300-500mm

-

Max. Use Temperature:

-

1100℃

-

Application:

-

Wooden Pellet/ Furnace/ Boiler

Quick Details

-

Type:

-

Pellet igniter

-

Power Source:

-

Electric

-

Voltage:

-

120V, 220V, 230V

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

INNOVACERA

-

Dimension(L*W*H):

-

OD10.5*ID6.5*L78 mm

-

Weight:

-

0.3 KG

-

Working Temperature Range:

-

-50 - 1100 ℃

-

Core Components:

-

MCH

-

Color:

-

White

-

Density:

-

3.7g/cm3

-

Power:

-

150-255W

-

Thermal Conductivity:

-

25W/(m.k)

-

Wire:

-

300-500mm

-

Max. Use Temperature:

-

1100℃

-

Application:

-

Wooden Pellet/ Furnace/ Boiler

Specification:

Voltage: 120V / 230V

Power: 150W / 170W / 200W / 230W

Tube Size: OD10.5 × ID6.5 × L78 mm

Supporting Socket: NO.7

Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept)

Range of temperature: 800~1100 °C

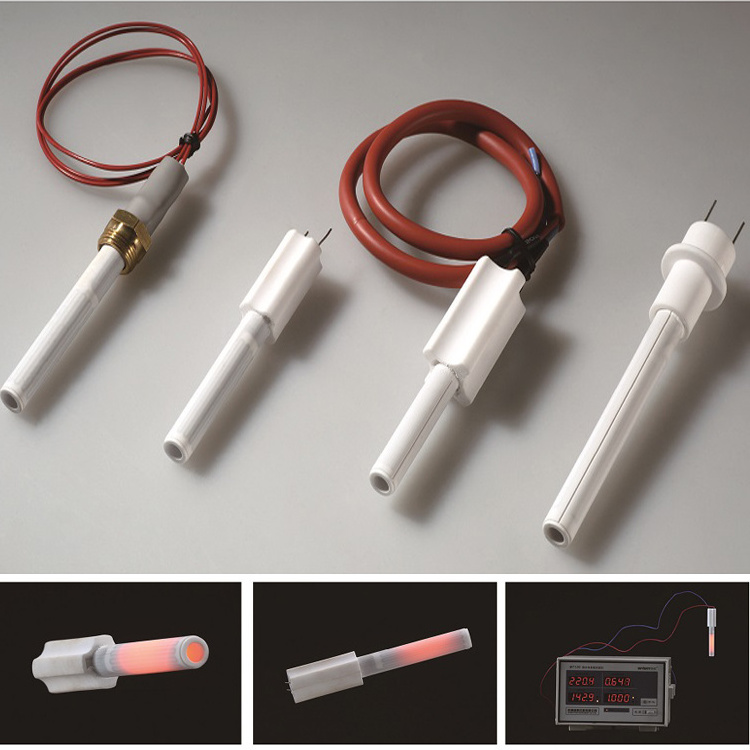

Ceramic igniter technology benefits:

* A fraction of the energy consumption compared to conventional element heater.

* Long-lasting (non-aging).

* Time to ignition 60~90 seconds.

* Tested to 100,000 cycles.

* Easy to install and retrofit.

* 800~1100°C at steady-state temperature.

* Impervious to oxidation and corrosion.

* Ignite kerosene, wood chips, split logs, coal briquettes or other biomass, corn, etc.

Applications:

* Kerosene fan heater

* Wood pellet, wood chips stove or boiler

* Small scale biomass industrial furnace ignition

* Incense burner

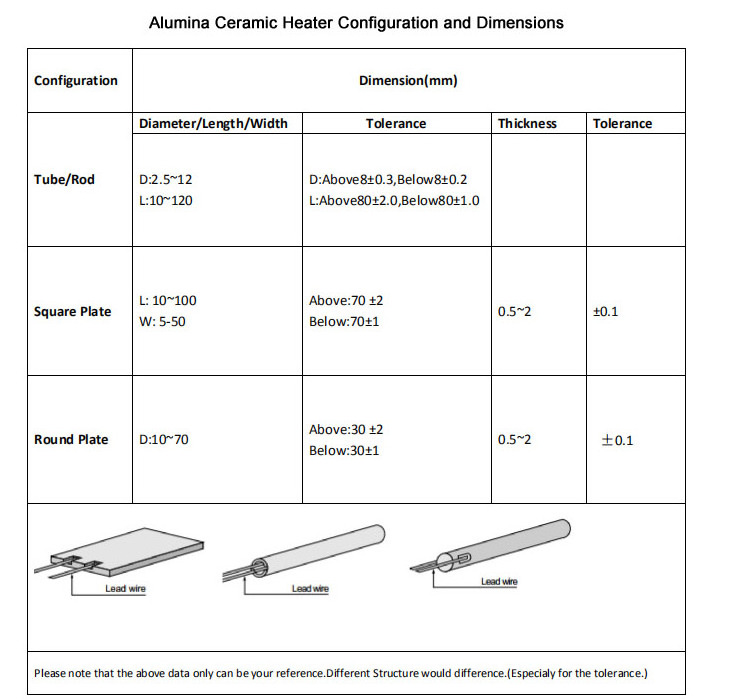

Alumina Ceramic Heater Design Structure

one pieces.

* Types:

■ Rectangular alumina ceramic heating element

■ Round shape alumina ceramic heating element

■ Rod shape alumina ceramic heating element

|

Thermal Properties for Alumina Heater

|

|

|

||

|

Item

|

Unit

|

Value

|

||

|

Vickers Hardness

|

Gpa

|

11.5

|

||

|

Flexural Strength

|

Mpa

|

300

|

||

|

Compressive Strength

|

Mpa

|

2000

|

||

|

Modulus of Elasticity

|

Gpa

|

300

|

||

|

Poisson's Ratio

|

---

|

0.22-0.23

|

||

|

Fracture Toughness

|

Mpam

1/2

|

3.5-4.0

|

||

|

Thermal Conductivity

|

W/(m·k)

|

25

|

||

|

Thermal Expansion Coefficient

|

10

-6

/℃

|

6.5-7.5

|

||

|

Thermal Shock Resistance

|

△T℃

|

200

|

||

|

Maximum Use Temperature

|

℃

|

1600

|

||

|

Dielectric Strength

|

KV/mm

|

>12

|

||

|

Dielectric Constant

|

εr

|

9-10

|

||

|

Dielectric Loss Angle (1MHz)

|

---

|

0.0002

|

||

|

Volume Resistivity

|

Ω.m

|

>10

15

|

||

|

Specific Heat

|

J/(kg·k)

|

0.78x10

3

|

||

ABOUT INNOVACERA

INNOVACERA is a professional high-tech enterprise, cooperate with Chinese University in advanced materials, many products are awarded as high-tech products and obtain patents.

Xiamen INNOVACERA engages in R&D, manufacturing and selling the products of advanced ceramic materials, including Alumina, Zirconia, Boron Nitride, Silicon Nitride, Machinable Glass Ceramic and other advanced materials. Through different manufacturing processes, we supply metallized ceramic components, alumina heater, ceramic pump components and other ceramic components as request.

EXHIBITION

---

>>> We delivery the order on time, competitive price, high quality and long service to our customers.

FAQ

Q1. Do you offer samples?

A: Yes, we'll offer you samples if we have stock, but some will charge sample fee. Shipping cost will pay by customer.

Q2. What is your terms of payment?

A: T/T in advance, Western Union, Alipay, Paypal.

Q3. How about your delivery time?

A: Depends on the requirement of the producst, according to the materials, dimensions and the manufacture process.

Q4. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: What else products do you offer?

A: We provide the products of advanced ceramic materials, including Alumina, Zirconia, Boron Nitride, Silicon Nitride, Machinable Glass Ceramic and other advanced materials.