- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Jeta

-

Model Number:

-

JT-HY330

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

8500*1800*1900mm

-

Weight:

-

5500 KG

-

Max Speed:

-

400m/min

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automaticity:

-

Full automatic

-

Name:

-

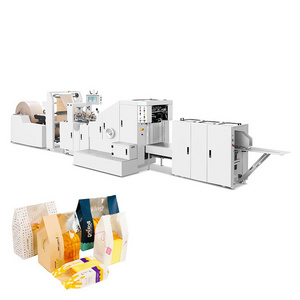

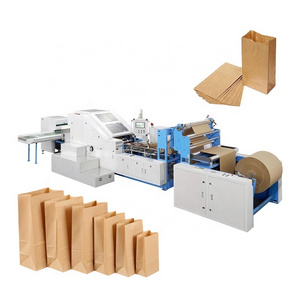

v bottom grocery paper bag making machine

-

Product name:

-

Automatic sharp bottom paper bag machine

-

Suitable material:

-

Brown Kraft

-

Usage:

-

Paper bag, food bag ,shopping bag

-

Model:

-

JT-HY330

-

Certification:

-

CE Certificatio

-

Delivery time:

-

As you wish

-

Advantage:

-

Low Consumption High Efficiency

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

GARBAGE BAG

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Jeta

-

Model Number:

-

JT-HY330

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

8500*1800*1900mm

-

Weight:

-

5500 KG

-

Max Speed:

-

400m/min

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automaticity:

-

Full automatic

-

Name:

-

v bottom grocery paper bag making machine

-

Product name:

-

Automatic sharp bottom paper bag machine

-

Suitable material:

-

Brown Kraft

-

Usage:

-

Paper bag, food bag ,shopping bag

-

Model:

-

JT-HY330

-

Certification:

-

CE Certificatio

-

Delivery time:

-

As you wish

-

Advantage:

-

Low Consumption High Efficiency

Useage:

This CE standard full automatic high speed v bottom grocery paper bag making machine is used for forming the paper bag in one process from roll paper, edge folding, tube forming, cutting, gluing, bottom folding, bottom gluing and finishing bag. Easy operation, low power consumption, high efficiency. It is an ideal machine for producing food bags like bread bags, KFC bags and McDonald’s bags.

This CE standard full automatic high speed v bottom grocery paper bag making machine is used for forming the paper bag in one process from roll paper, edge folding, tube forming, cutting, gluing, bottom folding, bottom gluing and finishing bag. Easy operation, low power consumption, high efficiency. It is an ideal machine for producing food bags like bread bags, KFC bags and McDonald’s bags.

Features:

*

[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine

.

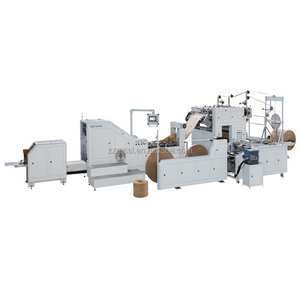

* This machine adopts touch screen man-machine interface, regardless of correction, trimming can be arbitrarily set, m alarm and operation state displayed on screen, easy to operate. The operation interface, English can be switched with m each other.

* Set the original German servo motor control with long motor, is making more stable.

* Printing color tracking system, using the German color photoelectric tracking precision, with automatic calibration w function.

* Photoelectric sensor limiting automatic control system, speed correction roll on saving the machine adjusting time and m reduce waste.

* Magnetic powder tension control with automatic constant tension control system, automatic calculation of roll diameter m to achieve constant tension control.

* Material handling with pneumatic lifting structure combination, can save manpower and reduce the loading and m unloading time.

* This machine adopts Germany original electrical system, to ensure the machine more stable, reliable operation of the m precision of the high-speed users from any menace from the "rear".

* Safety protection design of the machine has a new humanity; full face cover design, fully guarantee the safety and m product operator environment.

* This machine adopts touch screen man-machine interface, regardless of correction, trimming can be arbitrarily set, m alarm and operation state displayed on screen, easy to operate. The operation interface, English can be switched with m each other.

* Set the original German servo motor control with long motor, is making more stable.

* Printing color tracking system, using the German color photoelectric tracking precision, with automatic calibration w function.

* Photoelectric sensor limiting automatic control system, speed correction roll on saving the machine adjusting time and m reduce waste.

* Magnetic powder tension control with automatic constant tension control system, automatic calculation of roll diameter m to achieve constant tension control.

* Material handling with pneumatic lifting structure combination, can save manpower and reduce the loading and m unloading time.

* This machine adopts Germany original electrical system, to ensure the machine more stable, reliable operation of the m precision of the high-speed users from any menace from the "rear".

* Safety protection design of the machine has a new humanity; full face cover design, fully guarantee the safety and m product operator environment.

|

Model

|

JT-HY270

|

JT-HY330

|

|

Paper Thickness Range

|

30-100 GSM

|

30-100 GSM

|

|

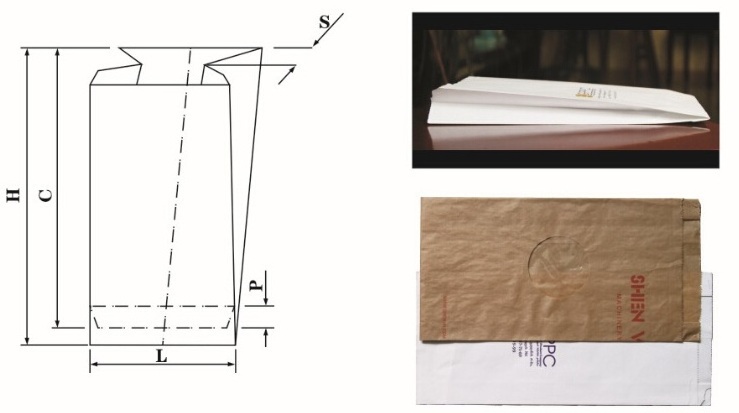

Paper Bag Width Range

|

80-270mm

|

80-330mm

|

|

Paper Bag Length Range

|

150-420mm

|

175-720mm

|

|

Side Folding Range

|

12-60mm

|

12-60mm

|

|

Production Precision

|

±0.2mm

|

±0.2mm

|

|

Machinery Speed

|

150-400 pcs /min

|

150-400 pcs /min

|

|

Maximum paper roll Width

|

900mm

|

900mm

|

|

Maximum. Paper roll Diameter

|

1200mm

|

1200mm

|

|

Total Power

|

16 KW

|

16 KW

|

|

Machine Weight

|

4500KGS

|

5500KGS

|

|

Machine Size

|

8500*1500*1900mm

|

8500*1800*1900mm

|

Hot Searches

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/22c65a5d5893304db66b95efbe1aaf82.jpg!/rotate/180)

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/67bb2dd17841372db2af280236f739af.jpg!/rotate/180)

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/0e9f852aed9b3102b62b4ddb1c784153.jpg!/rotate/180)

![[JT-HY330] Machine for Making Kraft Paper Bag / Paper Bags Production Machine / Craft Paper Bag Making Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/194a700227c331e7aae3219ed77bbef7.jpg!/rotate/180)

![[JT-HY270]CE Paper Bag Making Min Machine German Paper Bag Making Machine Manual Paper Bag Making Machine Price](https://cdn.bestsuppliers.com/seo_products_img/jeta/17c1ba615af43136bdaced2ec254d76c.jpg!/rotate/180/sq/300)