The forklift adopts s elf-propelled structure. This structure has the advantages of large rotational torque, smooth running, small inertia and non-slip. There are double insurance limit switches at the two ends of forklift.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

custmoized

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

20 T

-

Power (kW):

-

300

-

name:

-

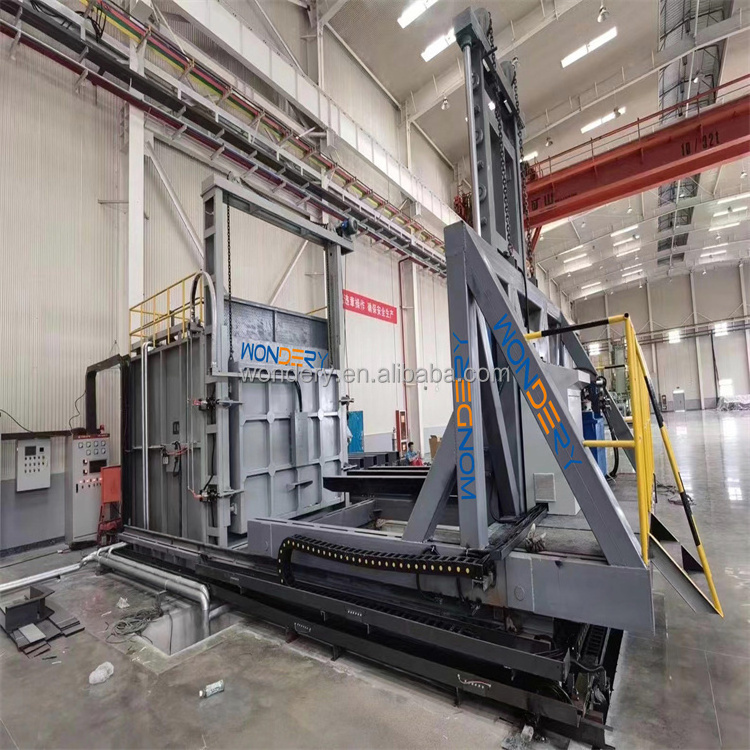

car bottom furnace

-

Energy:

-

Electric resistance

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

rate temperature:

-

1150 degree

-

type:

-

forklift type

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

bogie protection system:

-

limit switch at both ends

-

PLC control:

-

Siemens S7-200 PLC

-

control zone:

-

3 zones

-

loading capacity:

-

15 ton

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

WONDERY

-

Voltage:

-

custmoized

-

Dimension(L*W*H):

-

based on furnace size

-

Weight (T):

-

20 T

-

Power (kW):

-

300

-

name:

-

car bottom furnace

-

Energy:

-

Electric resistance

-

refractory lining:

-

silicate aluminum fiber precompressed blocks

-

rate temperature:

-

1150 degree

-

type:

-

forklift type

-

bogie driving mechanism:

-

reducing gear and motor or manual system

-

bogie protection system:

-

limit switch at both ends

-

PLC control:

-

Siemens S7-200 PLC

-

control zone:

-

3 zones

-

loading capacity:

-

15 ton

Product Application

The Forklift Car Bottom Heat Treatment Fast Quenching Process Furnace i s mainly used for fast quenching heat treatment of various steel workpieces.

trolley bogie hearth furnace trolley bogie hearth furnace trolley bogie hearth furnace trolley bogie hearth furnace

|

Specifications For Forklift Car Bottom Heat Treatment Fast Quenching Process Furnace

|

|

|

||

|

No.

|

Item

|

Technical Parameters

|

||

|

1

|

name

|

Forklift Car Bottom Heat Treatment Fast Quenching Process Furnace

|

||

|

2

|

fuel

|

electric

|

||

|

3

|

Power supply

|

380V 3phase 50HZ or customized

|

||

|

4

|

Rated temperature

|

1150℃

(working temperature: 800-1100℃)

|

||

|

5

|

Control zone

|

3 zones

|

||

|

6

|

Effective working size

|

4000×1000×2400mm(L×W×H)

|

||

|

7

|

Heating element connection

|

Y

|

||

|

8

|

Temperature uniformity

|

±10℃

|

||

|

9

|

temperature control accuracy

|

±1.5℃

|

||

|

10

|

Loading capacity

|

15 tons

|

||

Main Features

1) High Performance Bogie Hearth Electric Resistance Furnace For Annealing Treatment is an all-fiber structure, saving about 60% of power consumption compared with the traditional brick hearth.

2) Heating components: high temperature resistance alloy wires and strips.

3) Low noise, energy-friendliness, and stable performance.

4) Advanced CAD design.

5) Years of experiences in heat treatment process.

Forklift Mechanism

Push Rod Sealing Mechanism

Name:

push rod sealing mechanism

Brand: domestic quality brand

Original: CHINA

The door and furnace door is tightly sealed together to prevent heat loss.

Material : 0Cr27AL7Mo2 (strip);

The resistance strips are produced through special molds, and are installed in the furnace wall by porcelain nails. And there is a

porcelain gasket between the fiber wall and the resistance strips to avoid short-circuit.

Control Cabinet

Name: GGD type electrical control cabinet

Brand: CHINT, SIEMENS, Schneider, Omron, etc.

Original: China, Germany, French, Japan, etc.