- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

condar

-

Material:

-

316L

-

Feature:

-

Corrosion Resistance

-

Size:

-

6.0mm-9.525mm

-

Package:

-

Plastic Bag+carton Box

-

Surface:

-

Lapping

-

Product:

-

Stainless Steel Bead

-

Product name:

-

Polished 316 Stainless Steel Float Ball Use For Auto Sparge

Quick Details

-

Grade:

-

300 Series

-

Application:

-

hardware

-

Hardness:

-

HRC 26

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

condar

-

Material:

-

316L

-

Feature:

-

Corrosion Resistance

-

Size:

-

6.0mm-9.525mm

-

Package:

-

Plastic Bag+carton Box

-

Surface:

-

Lapping

-

Product:

-

Stainless Steel Bead

-

Product name:

-

Polished 316 Stainless Steel Float Ball Use For Auto Sparge

Polished 316 Stainless Steel Float Ball Use For Auto Sparge

Polished 316 Stainless Steel Float Ball Use For Auto Sparge

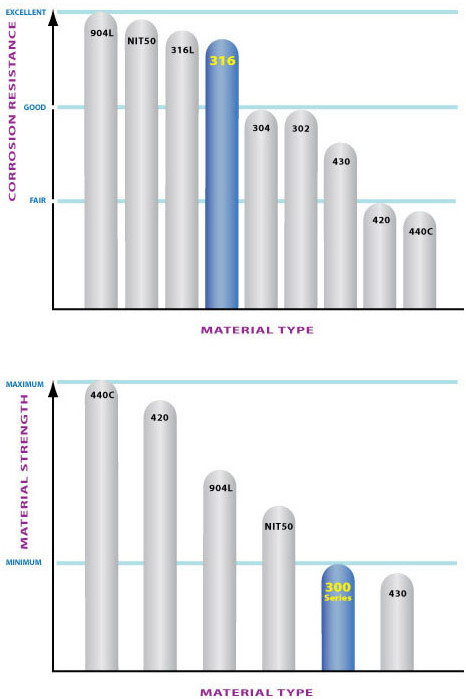

Stainless Steel Balls 316 Grade 100 are commonly used in trigger sprayers bearings, dispenser valves, body jewelry, lotion pumps, quick-disconnect couplings and aerospace applications. Also known as marine grade or surgical stainless steel, type 316 stainless steel is highly resistant to corrosion and pitting in aggressive environments with exposure to acidic compounds, chemicals, saltwater, and chlorides. Stainless 316 precision ball bearings are widely used in the food, fruit, and brewing industries, as well as marine and medical applications. Stainless steel 316 is tough but it can be machined, drilled, and tapped with moderate difficulty.

Excellent corrosion resistance, good oxidation resistance, high resistance to pitting and crevice corrosion, excellent durability, non-hardenable by heat treatment, solution treatment annealing, excellent weldability, excellent formability, forgeable, excellent toughness, ductile, cold workable, extremely low magnetic properties

Precision ball bearings, dispenser and aerosol valves, lotions pumps, locking mechanisms, agitators, animal feeders, trigger sprayers, finger pump mechanisms, food processing and medical applications, breweries.

Refer to our "Guide to STAINLESS" for grades, shapes and various properties.

product details:

AISI type 316 stainless steel balls offer excellent corrosion resistance and resistance to sulphuric acid compounds. This austenitic steel includes 2-3% molybdenum. Type 316 balls are used in trigger sprayers, bearings, dispenser valves, body jewelry, lotion pumps, quick-disconnect couplings and aerospace applications. Type 316LVM balls are used in jewelry, human implant and other medical applications.

|

AISI 316 |

|

|

SIZE RANGE |

0.50mm (.020") up to 2" |

|

GRADES |

50, 100, 200, 500, 1000, 2000 |

|

|

|

|

CHEMICAL COMPOSTION |

|

|

CHROMIUM |

16%-18% |

|

CARBON |

.08% MAX. |

|

NICKEL |

10%-14% |

|

MANGANESE |

2% MAX. |

|

SILICON |

1% MAX. |

|

PHOSHOROUS |

.045 % MAX. |

|

SULPHUR |

.03% MAX. |

|

MOLYBDENUM |

2%-3% |

|

|

|

|

MECHANICAL PROPERTIES |

|

|

TENSILE STRENGTH |

80,000 TO 120,000 PSI |

|

YIELD STRENGTH |

45,000 PSI |

|

ELONGATION IN TWO INCHES |

10%-15.0% |

|

REDUCTION IN AREA |

55.0%-65.0% |

|

MODULUS OF ELASTICITY |

28,000,000 PSI |

|

DENSITY |

.288 LBS./CU.IN. |

|

|

|

|

PHYSICAL CHARACTERISTICS |

|

|

CORROSION RESISTANCE |

EXCELLENT |

|

MAGNETIC |

NO |

|

Product Name |

Stainless steel ball 316L(Ocr19Ni12MO2) |

|||||||

|

Specification |

Φ0.5mm—Φ50.8mm |

|||||||

|

Grade |

G100-G1000 |

|||||||

|

Feature |

Austenitic steel, the most suitable for industries with high corrosion requirements,hardness <=28 degrees, non-magnetic, strong ability to resist rust. |

|||||||

|

Applications |

Valves, perfume bottles, medical equipment, nail polish bottle, cosmetic packaging, air conditioners and other household appliances. |

|||||||

|

Chemical composition |

C |

Ni |

Si |

M n |

P |

S |

Cr |

Mo |

|

<=0.08 |

12.0-15.0 |

<=1.0 |

<=2.0 |

0.045 |

0.03 |

16.0-18.0 |

2.0-3.0 |

|

1. Made of magnetic material and have a higher through hardness than other stainless steel balls.

2. AISI440C stainless steel balls are considerably resistant to corrosion from water, steam, oil, gasoline and alcohol.

3. Balls are passivated.

4. International standard: X105CrMo17 / 440C / 1.4125 / Z100CD17 / 95X18 / 9Cr18Mo / SUS440C

Features & Specifications

(1) Raw material traceability.

(2) Steady heat treatment technology.

(3) High precision (good roundness/roughness/hardness).