With vaccum holes on the mandrel to adsorb paper while automatic running

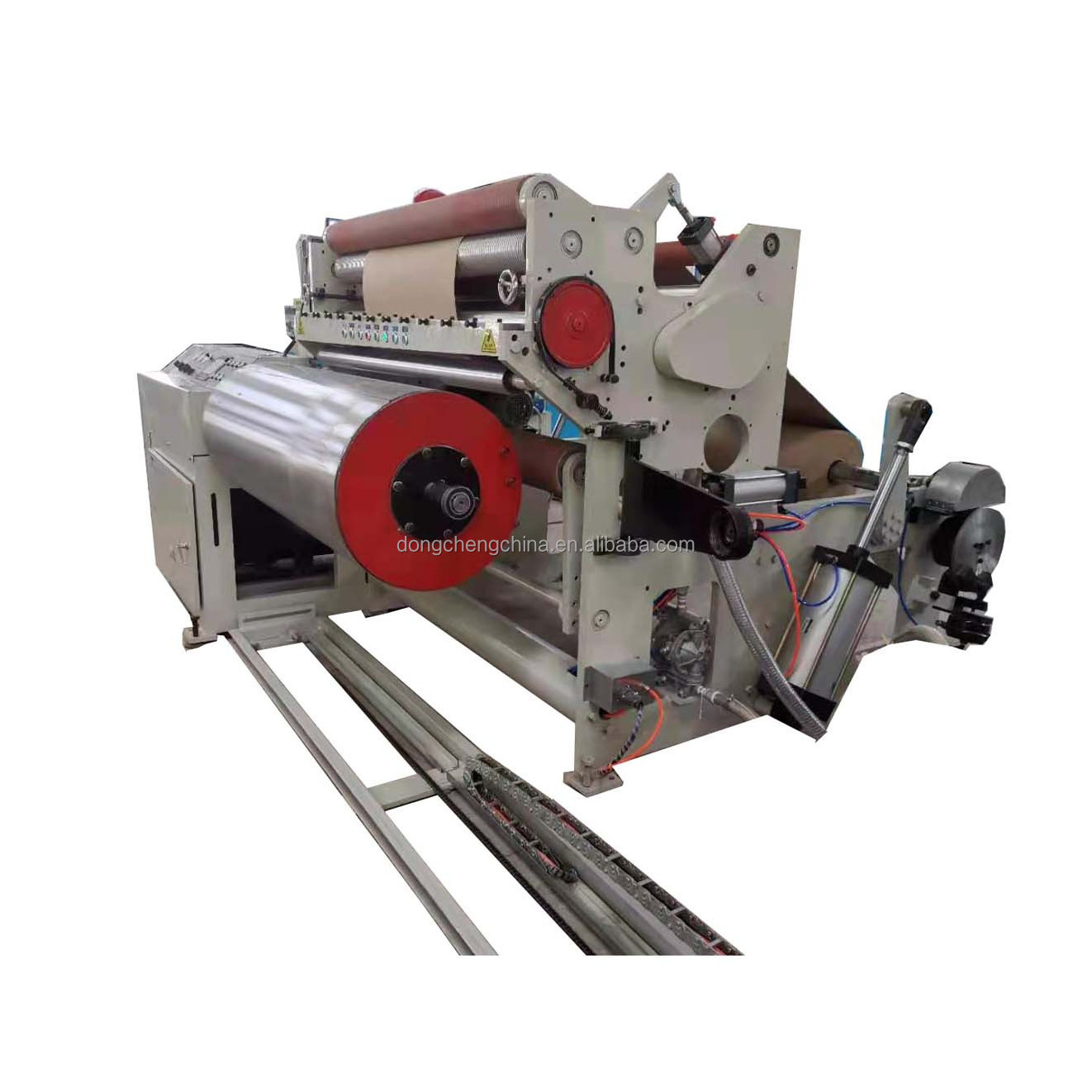

Pneumatic extension

|

Parameter/Model

|

ZPJ-1300

|

ZFJ-1600

|

ZPJ-1600

|

ZFJ-2200

|

||

|

Paper tube length

|

Max.1300mm

|

Max.1600mm

|

Max.1600mm

|

Max.2200mm

|

||

|

Paper Tube diameter

|

280~600mm

|

Max.1350mm

|

280~600mm

|

Max.1350mm

|

||

|

Paper tube thickness

|

1~35mm

|

76mm

|

1~35mm

|

76mm

|

||

|

production efficiency

|

200~500pcs/day

|

Hydraulic

|

200~500pcs/day

|

Hydraulic

|

||

|

Cutting Type

|

automatic circle blade cutting

|

50~1600mm

|

automatic circle blade cutting

|

50~2200mm

|

||

|

Tube Unloading tpe

|

pulling carriage

|

Max.1350mm

|

pulling carriage

|

Max.1350mm

|

||

|

Mandrel type

|

Pneumatic extension

|

Hydraulic

|

Pneumatic extension

|

Hydraulic

|

||

|

Gluing type

|

Automatic

|

200m/min

|

Automatic

|

200m/min

|

||