- Product Details

- {{item.text}}

Quick Details

-

Power:

-

150kw-200kw

-

Dimension(L*W*H):

-

72*6.5*5.8M

-

Weight:

-

5000 KG

-

Marketing Type:

-

New Product

-

introduction:

-

pasta maker machine

-

Main machine:

-

Extruder

-

install power:

-

200KW/150KW

-

Capacity:

-

260-500kg/h / 800-1200kg/h

-

Size:

-

72*6.5*5.8m/61*6.3*5.5m

-

local service location:

-

none

-

Feature:

-

High Efficiency

-

Material:

-

stainless steel

-

Final product:

-

pasta/macaroni/spaghetti/italian noodle

-

Operation:

-

Fully Aotomatic

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Arrow

-

Voltage:

-

220V/380V / 440V or Customization

-

Power:

-

150kw-200kw

-

Dimension(L*W*H):

-

72*6.5*5.8M

-

Weight:

-

5000 KG

-

Marketing Type:

-

New Product

-

introduction:

-

pasta maker machine

-

Main machine:

-

Extruder

-

install power:

-

200KW/150KW

-

Capacity:

-

260-500kg/h / 800-1200kg/h

-

Size:

-

72*6.5*5.8m/61*6.3*5.5m

-

local service location:

-

none

-

Feature:

-

High Efficiency

-

Material:

-

stainless steel

-

Final product:

-

pasta/macaroni/spaghetti/italian noodle

-

Operation:

-

Fully Aotomatic

Product Description

|

Model

|

Host Power

|

Output

|

|

ETT65 Extruded Instant Noodle Process Line

|

55KW

|

150-250kg/h

|

|

ETT78 Extruded Instant Noodle Process Line

|

75KW/110KW

|

300-400kg/h

|

|

ETT98 Extruded Instant Noodle Process Line

|

200KW/250KW

|

600-800kg/h

|

|

LT100 Extruded Instant Noodle Process Line

|

75KW

|

70-100kg/h

|

|

Model

|

Install Power

|

Output

|

|

LTP-100 Pasta Instant Noodle Process Line

|

114.55

|

100-120kg/h

|

|

LTP-200 Pasta Instant Noodle Process Line

|

147.12

|

200-230kg/h

|

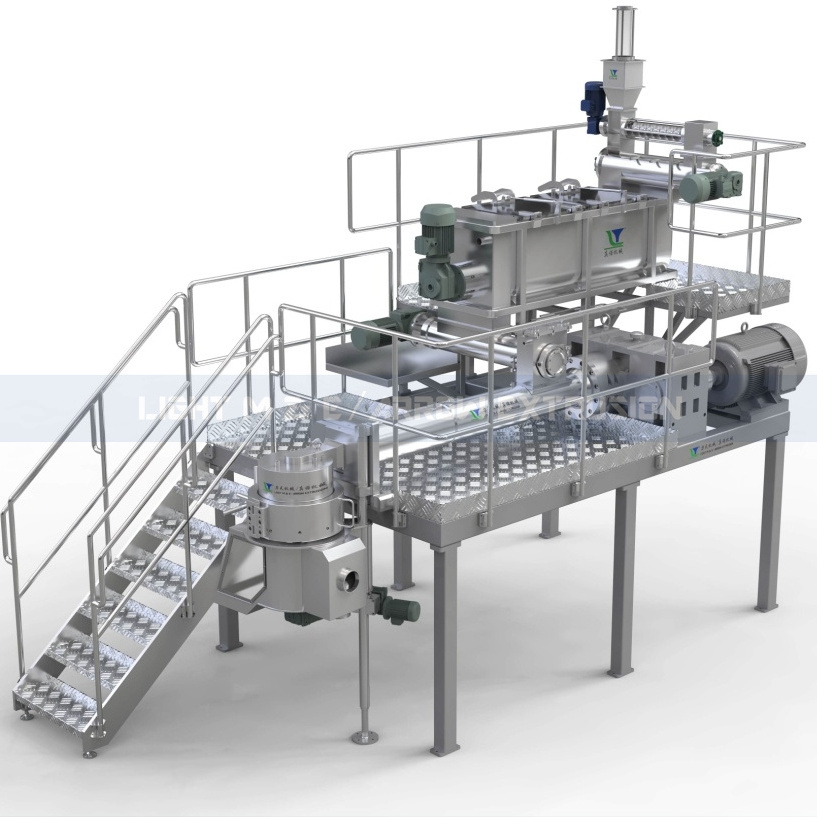

The Pasta Macaroni Vermicelli Instant Noodle Process Line

is a large-scale project and it can be customized to meet the specific needs of customers in terms of model and output. The line typically includes various stages, such as dosing and extrusion, cutting, drying, and packaging. The system can be equipped with a central control system to enable automatic operation, real-time monitoring, and reduce labor costs. This can help to improve efficiency and productivity, resulting in higher output and lower production costs. It is a suitable project for commercial and industrial use.

Application Display

Our machines produce high-quality pasta and extruded noodle samples with various shapes and sizes. The finished products have a smooth surface and a consistent texture, making them ideal for use in a variety of dishes.

Machine Details

Pasta Extruder

Efficiently extrudes different

shapes

and sizes of pasta. Easy to clean with stainless steel and quick-connect pipelines.

Double Screw Extruder

The double screw design allows for more precise control of the extrusion process, resulting in a more consistent product.

Supporting feet:

The supporting feet are strong and stable.

Distributor:

spread the material evenly on the mesh belt, and the thickness of the material spreading is uniform.

Dehumidification fan:

independent dehumidification fan, which is good for dehumidification.

Door panel:

box-type thermal insulation door, easy to open, easy to clean, and good sealing performance.

The pellet process line

uses potato starch, potato flour, corn starch, corn powder, wheat flour, cassava starch etc. as main materials, by the process of mixing, extruding, shaping and drying to produce dried double layer 3D pellets.

Hot Searches