- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Depends

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Depends

-

Warranty:

-

3 years,all life service

-

Machinery Capacity:

-

500L~50,000L

-

Product Name:

-

Glycol water tank for cooling conical fermenter brew system

-

Washing system:

-

Washing CIP cleaning, Omni spray washing

-

Material:

-

Stainless Steel 304

-

Control method:

-

Manual, semi-automatic, full-automatic

-

Tank outside:

-

Hairline polishing

-

Tanks inside:

-

Pickling and passivating treatment

-

Cone:

-

160 Degree Bottom

-

Cooling jacket:

-

Dimple Plate

-

Terms of Payment:

-

T/T or L/C

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Colombia, Algeria, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan

-

Certification:

-

CE/ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hulk Equipment

-

Voltage:

-

Adjustable

-

Power:

-

Depends

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Depends

-

Warranty:

-

3 years,all life service

-

Machinery Capacity:

-

500L~50,000L

-

Product Name:

-

Glycol water tank for cooling conical fermenter brew system

-

Washing system:

-

Washing CIP cleaning, Omni spray washing

-

Material:

-

Stainless Steel 304

-

Control method:

-

Manual, semi-automatic, full-automatic

-

Tank outside:

-

Hairline polishing

-

Tanks inside:

-

Pickling and passivating treatment

-

Cone:

-

160 Degree Bottom

-

Cooling jacket:

-

Dimple Plate

-

Terms of Payment:

-

T/T or L/C

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Colombia, Algeria, Sri Lanka, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan

-

Certification:

-

CE/ISO

Glycol water tank for cooling conical fermenter brew system

If you want to have reliable temperature control over your fermentation and storage temperatures, we recommend looking into a complete glycol system for your beer.

A properly set-up/sized glycol system will allow you to independantly control your fermentation vessels, storage tanks.

Product Description

|

Item No.

|

A Complete Set of

glycol water System will include below components

|

|

|

|

|||

|

1

|

Glycol water tank

|

|

|

|

|||

|

2

|

Cold water tank (for brewhouse capacity upper 1000L/batch)

|

|

|

|

|||

|

3

|

Industrial Chiller

|

|

|

|

|||

|

4

|

Glycol water Pump

|

|

|

|

|||

|

5

|

Cold water Pump (optional with item 2)

|

|

|

|

|||

|

6

|

Glycol water pipeline

|

|

|

|

|||

When will you need the glycol system?

2. Fermentation:

During this step, yeast will begin to consume sugars and release heat as a result.

Like an anxious driver flooring the gas pedal, this can lead to overheating during the process.

HULK glycol system will help put on the brakes, letting you have better control of internal temperatures and fermentation as a whole, and giving you more quality control over your beer.

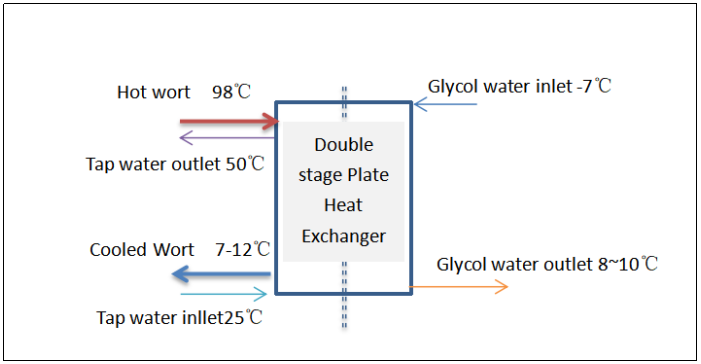

· Wort production process, glycol water working together with tap water to cool down the wort from around 98 degree to 7~12 degree.

Notes: tap water can flow back to HLT for further using.

Installed picture of Plate heat exchanger

there are 2 types of PHE:

A - Single stage (cold water VS wort)

B - Double stage (Glycol water VS wort VS tap water)

Glycol Water Tank with fermentors

Industrial Chiller

All our Beer brewing Equipments, are equipped with high quality sanitary parts, specially customized for each of our customer.

Glycol & Water Proportion

To save on costs, you’ll want to make sure that you use a proper mix of glycol and water when setting up your cooling system.

Too much glycol will leave you with a freezing point far below what’s necessary while wasting funds on refrigerant.

Too little, and you risk the entire system freezing, leaving the fermentation process to proceed unchecked!

Generally, depending on the total effective volume of tank, we recommend the propotion of

glycol and water is 1:3

, which can ensure the lowest temperature going to

-20 degree

without freezing.

Brewing beer is both rewarding and fun, especially if you enjoy designing systems that work at peak efficiency.

Make sure you follow proper procedures when working with cooling systems, and use HULK glycol system to keep your equipment working at top performance.

This will have you worrying less about the process and focusing more on brewing your best craft beers!

Related Products

We have separate chaptor pages for other related system, please click below for further details.

You only need to let us know your basic requirements.

Our

HULK guys

will collect all these turnkey brewery system information into an independent Quotation PDF file for your reference.

Why Choose HULK

We develop relationships that make a positive difference in our customer's life!

We create new and unexpected possibilities, providing innovative solutions for your future!

See below to know how customers evaluate HULK.

Our Service

We provide you with full advisory turnkey brewery services and discuss the matter with you thoroughly in order to find the best solution for your Beer Brewing project.

Providing 2D&3D Beer brewing tanks, brewhouse, brewery production line drawing service, on-going technical support, and lifetime on-line service is the core of HULK Value.

Packing & Delivery

All Brewhouse brewing system products will be packed up with foam and film safely.

- Assembles and fittings are carefully packed and boxed in crates

- Detailed packing list will be emailed to you once the goods are loaded, which is much convenient for you to check and unload goods into position quickly

Contact Us

Hulk brewery equipment company, with over 10 years sales and R&D experience, desire to provide comprehensive brewing business solutions for you. We are happy to deal with OEM & Customized orders from customers all over the world. Keep developing, improving, listening, and learning from our customers, a long-term cooperation is the bone of hulk.

Our success is not only due to the quality of our work, it’s down to attitude, our approach and the way we treat our clients.

Hot Searches