- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

DBHC-TC500

-

Voltage:

-

220V 50Hz

-

Dimension(L*W*H):

-

6000*1500*1950mm

-

Weight:

-

800 KG

-

Max Speed:

-

20-250pcs/min, 120pcs/min, 220pcs/min

-

Product name:

-

DBHC-TC500

-

Print Material:

-

Machine suitable for BOPP,CPP,PP,LDPE,HDPE etc materials

-

After-sales Service Provided:

-

Online Support

-

Service:

-

Line Service

-

Bag length:

-

50-2000mm

-

Bag width:

-

25-1600mm

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Patch Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

DBHC-TC500

-

Voltage:

-

220V 50Hz

-

Dimension(L*W*H):

-

6000*1500*1950mm

-

Weight:

-

800 KG

-

Max Speed:

-

20-250pcs/min, 120pcs/min, 220pcs/min

-

Product name:

-

DBHC-TC500

-

Print Material:

-

Machine suitable for BOPP,CPP,PP,LDPE,HDPE etc materials

-

After-sales Service Provided:

-

Online Support

-

Service:

-

Line Service

-

Bag length:

-

50-2000mm

-

Bag width:

-

25-1600mm

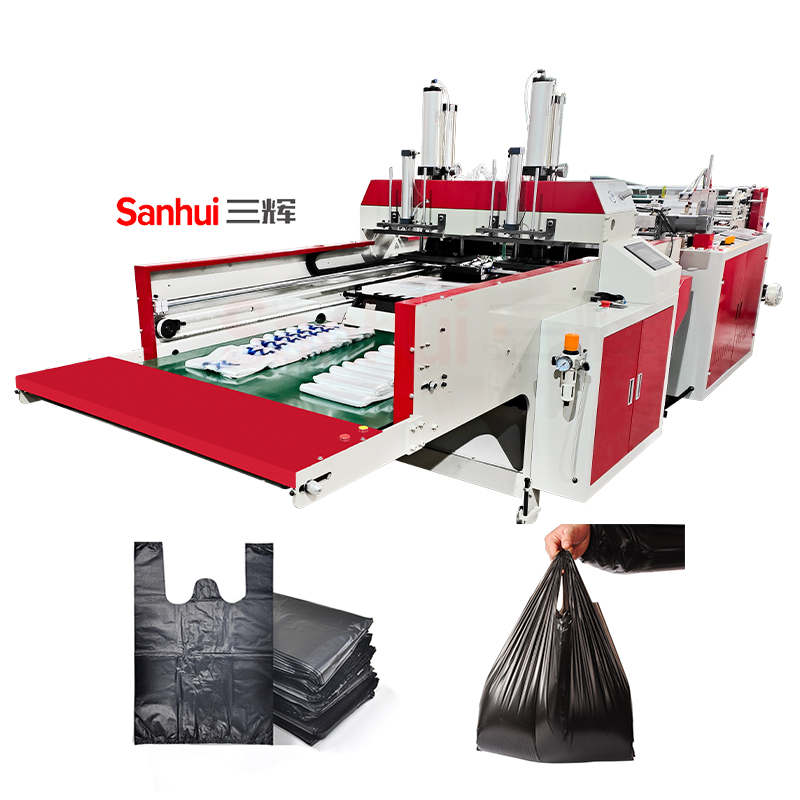

Products Description

Introduction

This automatic bottom sealing poly bag making machine is applied to manufacturing and printing the colored vest bags made of HDPE,LDPE roll film. It adopts PLC control, double servo (step) motor fixed length and the liquid crystal touch screen actual display to finish the feeding, sealing, cutting, punching holes and transporting only in one process. It is of high degree of automation and good economic result.

Machine Feature

1.Unwinding tension with AC inverter automatic control.

2.Easy operate and adjustment side fold device.

3.Turnover sealing knife,easy clean design.

4.The whole set of bags has design of swaying,no paste between two bags mouth.

5.Multitem automatic warning,automatic stop design.

2.Easy operate and adjustment side fold device.

3.Turnover sealing knife,easy clean design.

4.The whole set of bags has design of swaying,no paste between two bags mouth.

5.Multitem automatic warning,automatic stop design.

|

Model

|

DBHC-TC500

|

|

Bag Making Speed

|

140-200pcs/minX2

|

|

Bag Width

|

300mmX2

|

|

Bag Length

|

650mm

|

|

Bag Thickness

|

0.015-0.035mm

|

|

Total Power

|

7kw

|

|

Air pressure

|

5kg/cm2

|

|

Machine Weight

|

1400kg

|

|

Machine Size

|

6000X1400X1600mm

|

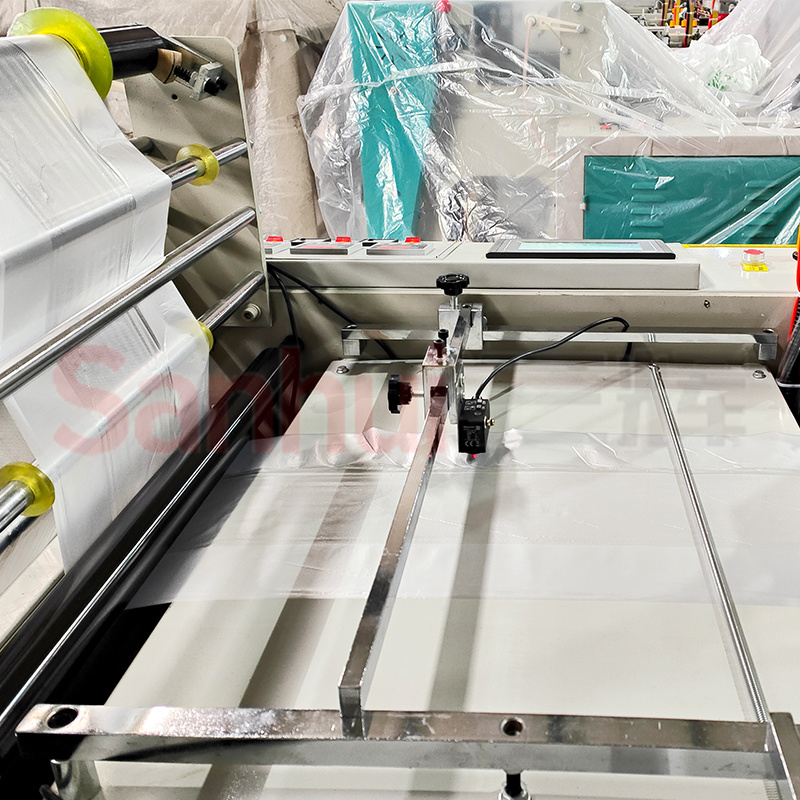

Machine Inroduction

①

Unwinding part

②

automatic tension control

③

Sealing and cutting knife device

③ Sealing and cutting knife device

④

Automatic control

⑤

Hydraulic air cylinder punch

⑥

Automatic collect table

Detail display

a.

Easy operate

unwinding part,

reduce labor intensity

a.Unwinder part has the EPC and automatic tension control.

3

Sealing and cutting knife device

a.

Double sealing knife

Each sealing knife and feed device are controlled independently.

Each sealing knife and feed device are controlled independently.

b.

Sealing knife "turnover" device ,which easy to clean the knife ,which is better to keep the maintenance easy.

a.

One set EPC system to control two lines.

b.

This EPC system will enhance the productivity of machine.

c.When roll film feeding so fast that the film will move little left and right, with this EPC device to be control the film

a.Each stack of bag is very clean, and waste film from bag could be clean away

b.

It making sure each punching of the T-shirt shape is powerful

a.

Collect table adopts automatic collecting bag feeding.

b.

With gripper device,which is controlled,

which makes bag much more tidy.

Machine Display

Sample Display

Our Company

Packaging and Shipping

Hot Searches