- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

as per model

-

Year:

-

2023

-

Power (kW):

-

11 kW

-

Weight (KG):

-

2000 KG

-

Name:

-

waste tire recycling plant/tire recycling equipment prices

-

Raw material:

-

Waste Tyre Waste Plastic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Rubber Processing Machinery

-

Function:

-

Tire Powder Recycling Machine

-

Color:

-

Customers' Demand

-

End product:

-

Rubber Particle

-

Machine Type:

-

Fully Automatically Tire Recycling Machine

-

Capacity:

-

200kg/h-3000kg/h

-

Usage:

-

Used Tire Recyling

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuguang

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

as per model

-

Year:

-

2023

-

Power (kW):

-

11 kW

-

Weight (KG):

-

2000 KG

-

Name:

-

waste tire recycling plant/tire recycling equipment prices

-

Raw material:

-

Waste Tyre Waste Plastic

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Rubber Processing Machinery

-

Function:

-

Tire Powder Recycling Machine

-

Color:

-

Customers' Demand

-

End product:

-

Rubber Particle

-

Machine Type:

-

Fully Automatically Tire Recycling Machine

-

Capacity:

-

200kg/h-3000kg/h

-

Usage:

-

Used Tire Recyling

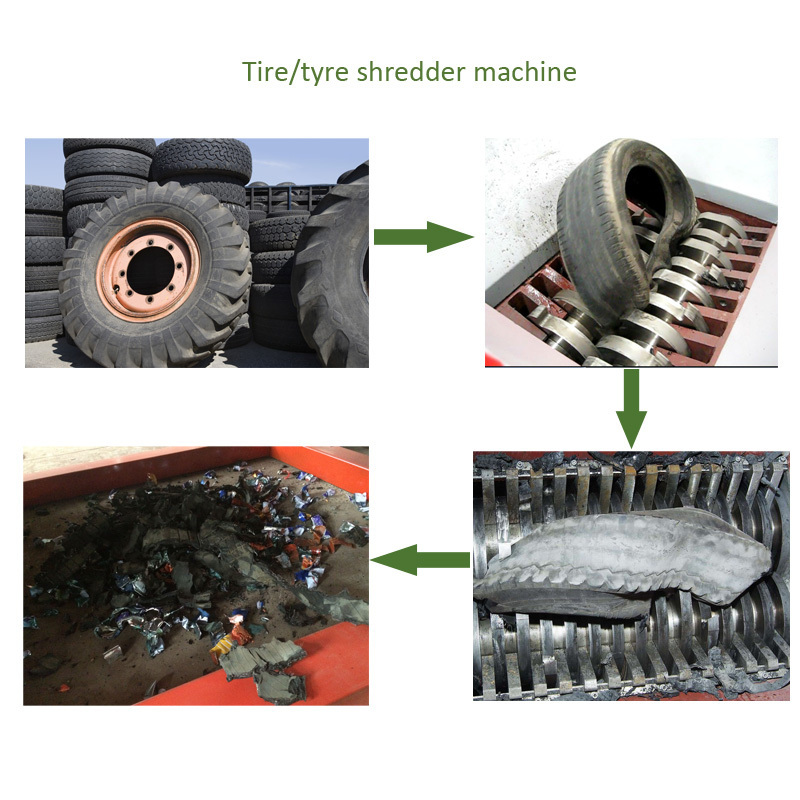

Tire shredder machine is used to shred the whole tire into rubber chips. Processing materials: waste tires, car tires, truck tires, trailer tires, whole tires with diameters of 600 mm and 1200 mm, etc. The final rubber chip size is determined according to customer requirements. we will customize the machine configuration of thetire shredder machine according to the specific requirements of each customer.

Working principle:

1.First, the steel wire tire decomposing equipment decomposes the steel wire tire into blocks.

2.Then the tire block is broken into (5-10cm) blocks by the tire shredder.

3.After the steel wire separator: the rubber and the steel wire are separated and processed into rubber particles. (10mm-20mm).

4. In the rubber pellet machine: crush the rubber particles to a smaller size (1mm-7mm).

5.After passing through the vibrating screen: sort the rubber particles of different sizes, and send the oversized particles back to the crusher Carry out secondary pulverization,.

6.Then fiber separator: remove foreign matter and fibers, then enter the rubber mill at room temperature for fine grinding, processed into fine rubber powder with a fineness of 5-80 mesh,

7.Finally bagged after a magnetic separation process Sales.

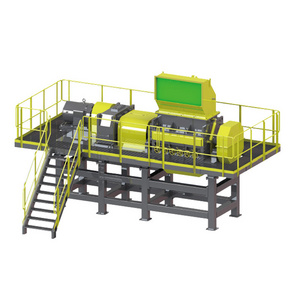

This whole plant will include Tire debeader---Tire shredder----Rubber crusher---Wire seperator ----Rubber particles machine--- Air separation equipment----Particle sieving machine.

Equipment can be configured according to actual needs

Consist of:

| No. | Machine | Model | Quantity | Power |

| Whole tire cut processing, get <50*50mm rubber crumb | ||||

| 1 | Wire de-bead | SX-1200 | 1 | 7.5KW |

| 2 | Big tire shredder | SG | 1 | based on model |

| 3 | Small tire shredder(optional) | SG | 1 | based on model |

| Rubber power processing, get 10-20 mesh rubber power | ||||

| 4 | Rubber crusher | PSJ-600 | 1 | 30KW |

| 5 | Wire separate | PSJ-450 | 1 | 22KW |

| 6 | Tire granule machine | PSJ-600 | 1 | 30KW |

| 7 | Selecte machine | SSJ-400 | 1 | 3KW |

| 8 | Screen machine | SSJ-400 | 1 | 1.5KW |

You can choose here below attached shredder model based on your detail demands:

SG-600,SG-800,SG-1000,SG-1200,SG-1500,SG-1800,SG-2000 model shredder.

You can choose here below attached two types wire de-bead:

|

|

|

| Hydraulic type | Electric Type |

Features:

1), iron/steel removing ratio>99.5%, fiber removing ratio>98%

2),adopt automatic control system for whole line, reduce labor cost;

3),no sewage and waste gas discharge, environment protection.

4), available capacity range of our tyre recycling lines at present: 400~3000kg/h

5), available finial rubber powder size: 20~30mesh.

Pictures:

1.Wire de-bead: to pull the wire inside of tires out for further process.

2.Shredder: put whole tyre into shredder to shred it into rubber crumb

3.Rubber crusher: crush rubber crumb into smaller size

4.Wire separator: separate wire from rubber particles

5.Tyre granulate machine,select machine,screen machine: crush and screen rubber particles into more small paticles,and separate nylone