- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

500 KG

-

Application:

-

Gold Froth Flotation Machine

-

Usage:

-

Mining Separatoion

-

Volume:

-

0.35-20 m³

-

Power:

-

16 kw

-

Color:

-

Customerized

-

MOQ:

-

1 Set

-

Quality:

-

100% Tested

-

Installation:

-

Technical Guidance

-

Product name:

-

Flotation Seperation Machine

-

Advantage:

-

Easy to Operate

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Changyi

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

500 KG

-

Application:

-

Gold Froth Flotation Machine

-

Usage:

-

Mining Separatoion

-

Volume:

-

0.35-20 m³

-

Power:

-

16 kw

-

Color:

-

Customerized

-

MOQ:

-

1 Set

-

Quality:

-

100% Tested

-

Installation:

-

Technical Guidance

-

Product name:

-

Flotation Seperation Machine

-

Advantage:

-

Easy to Operate

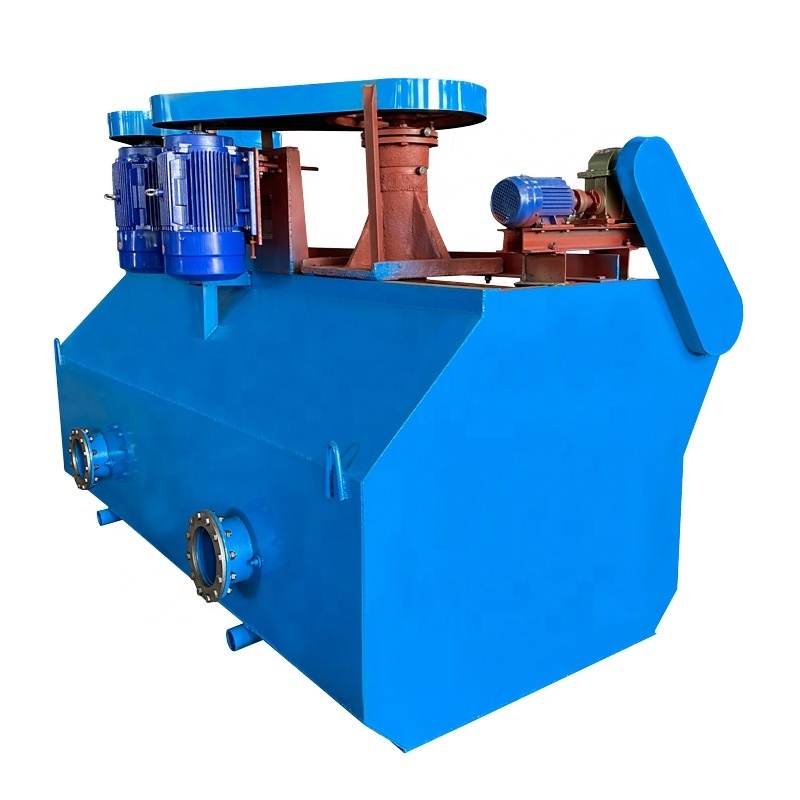

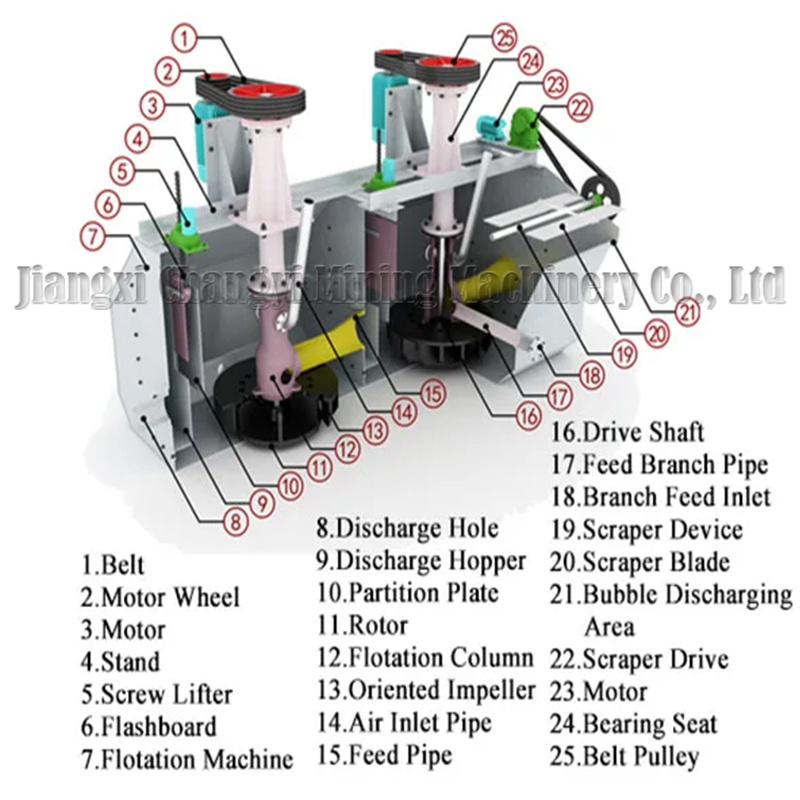

Product Description

Flotation machine is the abbreviation of floating concentrator, which refers to the mechanical equipment to complete the flotation process. In the floatation machine, the slurry is treated by mixing and aerating, so that some of the ore particles are selectively fixed on the bubbles, and the floating surface is scraped out to form foam products, while the rest is retained in the pulp to achieve the purpose of separating minerals. There are many structural forms of flotation machine, and the most commonly used one is mechanical stirring flotation machine.

Features of

Floatation Machine

(1) Large inspiratory capacity, small energy consumption;

(2) Self-priming air, self-priming pulp ability, horizontal configuration, do not need foam pulp;

(3) The circular speed of the impeller is low, the service life of easily worn parts is long, the gap between the impeller and the cover plate is large, and the increased gap between the impeller and the cover plate due to wear has less impact on the suction volume;

(4) The slurry in the tank is circulated up and down in a fixed flow direction, which is conducive to the suspension of coarse minerals.

Working Principle

The floatation machine is driven by the triangle belt of the motor to drive the impeller to rotate, resulting in centrifugal action to form negative pressure. On the one hand, the sufficient air is mixed with the slurry. On the one hand, the slurry is mixed with the medicine, and the foam is refined at the same time, so that the mineral adheres to the foam and floats to the slurry surface to form a mineralized foam. Adjust the height of the gate and control the liquid level, so that the useful foam is scraped out by the scraper.

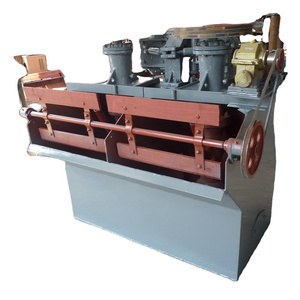

Details Images

It is mainly used for the separation of copper, zinc, lead, nickel, gold and other non-ferrous metals, and can also be used for the roughing and cleaning of ferrous metals and nonmetals.

Technical Parameters

|

Model

|

Effective volume

(m³)

|

Capacity

(m³/min)

|

Cell size

(mm)

|

Single slot weight

(t)

|

|

XK-0.35

|

0.35

|

0.18-0.4

|

0.7*0.7*0.7

|

0.5

|

|

SF-0.37

|

0.37

|

0.2-0.4

|

0.7*0.7*0.75

|

0.5

|

|

JJF-2

|

2

|

1-3

|

1.4*1.4*1.1

|

1.7

|

Note: Data only for reference, according to customer requirements for design and production.

Hot Searches