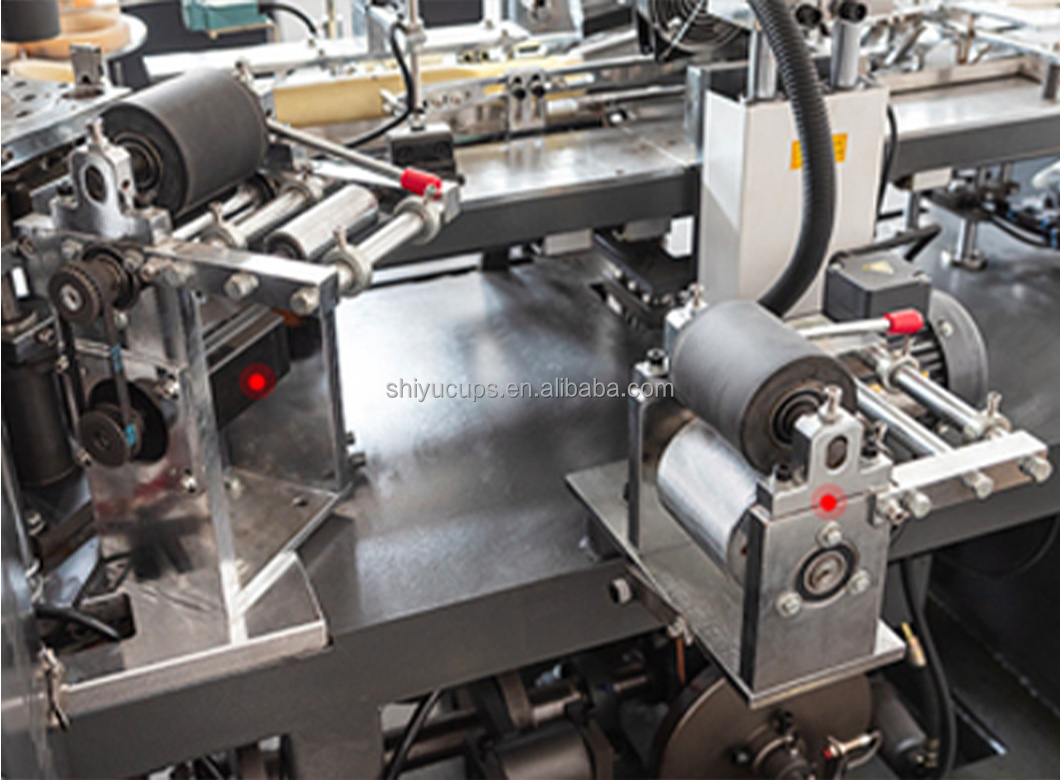

Control panel with good quality switches , temperature controller and speed converter. All the operation of machine can be finished easily by this panel

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

50/60HZ,380V/220V

-

Power:

-

4kw

-

Dimension(L*W*H):

-

2115*1000*1700mm

-

Weight:

-

1680 kg

-

Cup size:

-

4~16oz

-

working air source:

-

Air Pressure 0.5Mpa

-

cup side welding:

-

ultrasonic heater

-

Rated Speed:

-

70-90pcs / min

-

suitable paper weight:

-

140-350gsm

Quick Details

-

Production Capacity:

-

90 pcs/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

50/60HZ,380V/220V

-

Power:

-

4kw

-

Dimension(L*W*H):

-

2115*1000*1700mm

-

Weight:

-

1680 kg

-

Cup size:

-

4~16oz

-

working air source:

-

Air Pressure 0.5Mpa

-

cup side welding:

-

ultrasonic heater

-

Rated Speed:

-

70-90pcs / min

-

suitable paper weight:

-

140-350gsm

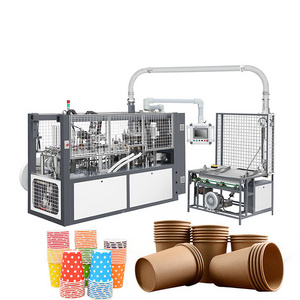

The SY-100 medium speed paper cup forming machine is based on the vertical axis paper machine. Through innovation and improvement, the stability and production speed of the whele machine have been greatly improved. It is suitable for the production of single and double-sided coated hot and cold beverage paper cups through continuous processes such as feeding, middle sealing into cylinder, cup mouth lubrication, upper curling, cup bottom, bottom heating, rolling, and finished product blowing. cream paper cups,

The SY-16 intelligent medium speed paper forming machine is an upgraded version of the vertical axis paper cup machine; ( The vertical axis paper machine has a capacity of 60-65 per minute, and the ZF. HC16 reaches 80-95 per minute)The overall steel plate body and the oil-eading system long-term normal and stable operation of the equipment;

|

Specification of paper cup

|

40ml-16OZ

|

|

Output

|

70-90pieces/min

|

|

Main motor power

|

4KW

|

|

Air Pressure Request

|

0.4m3/min, 0.5Mpa

|

|

Applicable raw paper

|

140-250g/㎡

|

|

Machine weight:

|

1680kg

|

|

Voltage Requirement

|

380v 50Hz/220 50Hz

|

|

Air Source

|

0.4m³/min

|

|

Package Size

|

2115×1000×1700mm

|

|

Cup side Welding

|

Ultrasonic heater

|

Control Panel

Electric System

Quality Brand electric System like Delta . Schneider

Main Turn plate

This model is equipped with 10 Cup molds, which operates faster than the old 8 Cup molds

Bottom Heater System

The new design adds a bottom heating system more than the old design which make the paper cup sealing effect is more better.

Bottom Paper Feeding Unit

New design : The steel plate presses the bottom paper to make the paper feeding more stably and smoothly

Hot Searches