- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Voltage:

-

380V

-

Weight:

-

4000 kg

-

Product name:

-

Roof Sheet Forming Machine

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Name:

-

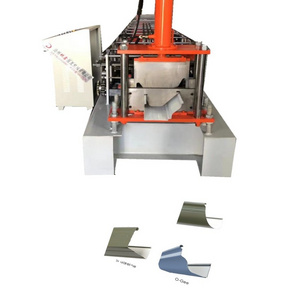

Accessary Roll Forming Machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

Colored Steel Roof Making Machine

-

Control system:

-

plc

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Voltage:

-

380V

-

Weight:

-

4000 kg

-

Product name:

-

Roof Sheet Forming Machine

-

After-sales Service Provided:

-

Engineers

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Name:

-

Accessary Roll Forming Machine

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Keywords:

-

Colored Steel Roof Making Machine

-

Control system:

-

plc

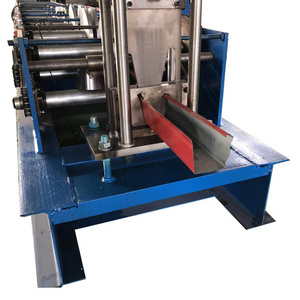

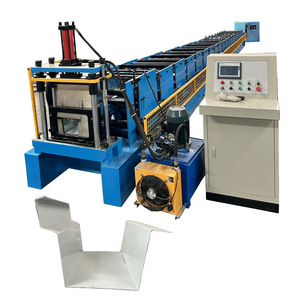

Products Description

Portable Seamless Gutter Machine Steel Gutter Making Machine

Our company specializes in the production of stainless steel color steel plates, stainless steel plates, and precision plate forming machines. U-shaped equipment is one of our equipments, we can make samples according to your design

|

Description

|

Explaination

|

|

Working speed

|

10-15 m/min(Shear time is not included)

|

|

Pressed plate thickness

|

0.3-3mm

|

|

Control mode

|

Panasonic PLC

|

|

Discharging rack

|

3T manual decoiler

|

|

Number of molding passes

|

12 lanes(Adjust according to the version)

|

|

Roll material

|

After finishing, the surface of 45# steel is chrome plated.

|

|

Shaft material and diameter

|

45# Steel finishing,Shaft diameter is¢85mm

|

|

Main engine power

|

5.5kw

|

|

Power of hydraulic station

|

4kw

|

|

Hydraulic pressure

|

12Mpa

|

|

Cutting mode

|

Shear after forming

|

|

Scissors material

|

Cr12Mov, quench HRC 58-62℃

|

|

Length tolerance

|

3m±1.5mm

|

|

Voltage

|

380V, 50HZ,3 phase(According to customer requirements can be adjusted)

|

|

Transmission mode

|

1.0 inch single row chain(Adjust according to the version)

|

|

Equipment form

|

slab-wall structure

|

|

Equipment color

|

blue and yellow

|

|

Equipment size

|

L*W*H— 8m*1.5m*1.2m

|

|

Date of delivery

|

80 days

|

|

Payment method

|

30% advance charge,70% pay off on delivery

|

Hot Searches