- Product Details

- {{item.text}}

Quick Details

-

Engine Brand:

-

HANGFA

-

Travel Speed:

-

15Km/h

-

Grade Ability:

-

30 Degree

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

kepai

-

Dimension(L*W*H):

-

3880*2980*2480 mm

-

Marketing Type:

-

Hot Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Yellow / red / geen / blue

Quick Details

-

Type:

-

Impact Roller

-

Power:

-

266000

-

Weight:

-

16000kg, 16000kg

-

Engine Brand:

-

HANGFA

-

Travel Speed:

-

15Km/h

-

Grade Ability:

-

30 Degree

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

kepai

-

Dimension(L*W*H):

-

3880*2980*2480 mm

-

Marketing Type:

-

Hot Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Yellow / red / geen / blue

P roduct description

Impact compactor, also known as impact roller ,Earthwork compactor and impact roller compactor, is a new type of towed roller that belongs to the roller.

The impact roller is pulled by the loader to drive an impact wheel, and the cement road and the roadbed are crushed and compacted by the weight of the impact wheel itself and the impact force during the advancement.

The development and application of impact roller has accelerated the development of geotechnical compaction technology and provided a new idea for solving the problem of subgrade quality hazard: such as effectively reducing post-construction settlement of subgrade and ensuring the overall stability of embankment; The roadbed and embankment of the forming subgrade are inspected and added to the inspection, and the overall strength and uniformity of the subgrade are improved. The pre-filling treatment of the collapsible loess foundation or the weak foundation is carried out to make the foundation meet the bearing capacity and Stable requirements; rebuild the impact crushing technology for old roads such as gravel pavement and cement concrete pavement, which can speed up the construction progress and meet the project quality requirements. At present, Almost all developed and developing countries, have applied impact rolling technology.

Impact rolling technology features

The impact roller uses a non-circular wheel to perform static pressure, enthalpy and periodic impact on the earth and stone material along the ground, and generates a strong shock wave with seismic wave propagation characteristics downward. Taking the impact compaction of the 25kJ tri-fold double-wheel impact roller on the slag and gravel roadbed as an example, after the roller is driven at a speed of 12km/h for 30 times, the average vertical earth pressure at the measured depth of 0.8m is 1366kPa, which is equivalent to The impact force generated by the ground is 200t~250t, and the impact function is super-heavy compaction work, which can increase the compactness of the deep underground soil and increase the compactness of more than 90% of the heavy standard. Some earth and stone materials have an effective compaction thickness of 1.5m, which has better compaction effect than the existing vibratory compaction machinery, and makes the pressed earth and stone filler closer to the elastic state.

Compared with the conventional road roller, the impact roller has different compaction process. Basically, it does not adopt the construction method of the existing roller compactor or partial overlap rolling, but the directional behavior of the deep diffusion of the impact force to the soil, and proposes a new impact mill. Pressure method and construction process. The two sides of the impact roller are 0.9m wide, and the inner circumference of the two wheels is 1.17m. The driving is twice, and the width of the punching is 4m. Each time the impact force is distributed to the soil body at an angle of (45°-Φ/2) according to the edge of the touch-off area of ??the roller. The second round of each pass passes through the center of the first two rounds of inner margins, forming a theoretical punching gap of 0.13 m each. When the second pass of the second pass is moved backwards by 0.2 m, the gap of the first pass is all rolled. The third pass is restored to the position of the first pass, and is sequentially carried out to the final pass. Various earth and stone roadbeds can be ground for 20~40 times to form a uniform reinforcement layer with a thickness of 1.0m~1.5m.

1. Reduce the post-construction settlement rate of embankments

2. Improve the overall strength and uniformity of the roadbed

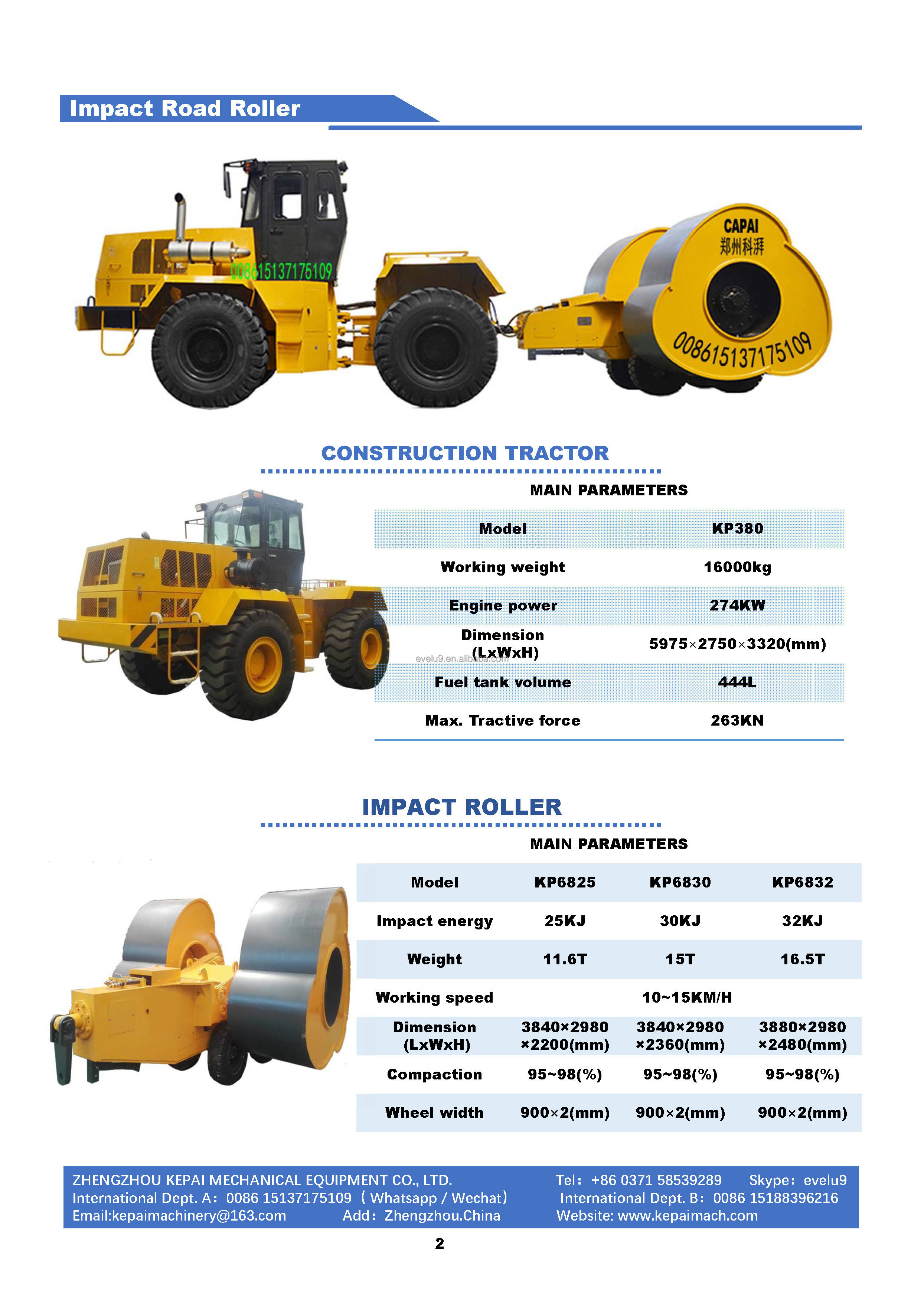

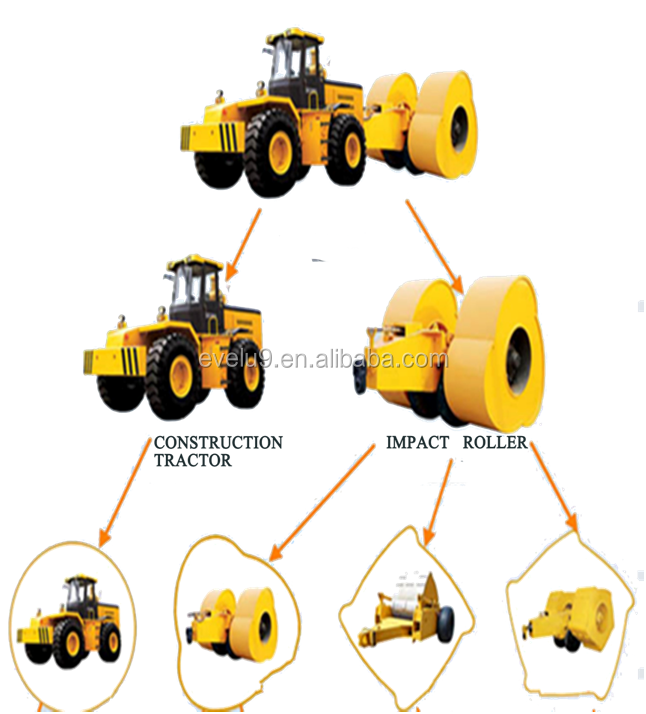

IMPACT COMPACTION EQUIPMENT COMPOSITION:

IMPACT ROLLER :

Main Technical Parameters of IMPACT ROLLER

CONSTRUCTION TRACTOR

Main Technical Parameters of CONSTRUCTION TRACTOR

| PACKING & SHIPPING |

OUR SERVICES AND SPARE PARTS

CLIENT COMMENT: