- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TT1000

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

50*8*6m

-

Year:

-

2021

-

Weight (KG):

-

20000 kg

-

Power (kW):

-

366Kw or customized

-

Name:

-

Scrap Second Hand Tyre Used Rubber Tires Recycling Machines

-

Shredder model:

-

Crushing and shredding

-

Function:

-

Makes rubber products smaller,and recycling waste scraps

-

Final product size:

-

Customize

-

Keyword:

-

High efficiency and high safety

-

Raw material:

-

All kinds of rubber products

-

Our Service:

-

Lifetime online service, technicians can be sent to the operation

-

Blade material:

-

9CrSi/D2/SKD-11/ Customized

-

Motor brand:

-

Siemens, Schneider, Panasonic,and China local famous brand.

-

Machine control:

-

PCL

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Tianyu

-

Marketing Type:

-

New Product 2022

-

Model Number:

-

TT1000

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

50*8*6m

-

Year:

-

2021

-

Weight (KG):

-

20000 kg

-

Power (kW):

-

366Kw or customized

-

Name:

-

Scrap Second Hand Tyre Used Rubber Tires Recycling Machines

-

Shredder model:

-

Crushing and shredding

-

Function:

-

Makes rubber products smaller,and recycling waste scraps

-

Final product size:

-

Customize

-

Keyword:

-

High efficiency and high safety

-

Raw material:

-

All kinds of rubber products

-

Our Service:

-

Lifetime online service, technicians can be sent to the operation

-

Blade material:

-

9CrSi/D2/SKD-11/ Customized

-

Motor brand:

-

Siemens, Schneider, Panasonic,and China local famous brand.

-

Machine control:

-

PCL

Recycling Background

At present, the number of waste automobile tires accumulated in the world has reached

3 billion

, and this number is still increasing at a rate of

1 billion per year increase

. Through the separation and crushing of tire opening equipment, various waste rubber products are pulverized into particles to realize the recycling and reuse of waste rubber, which not only can obtain

objective benefits

, but also

reduce environmental pollution.

The tire recycling line

is a

complete production line

for a series of waste tire recycling

operations such as

cutting, crushing, magnetic separation, fine crushing, grinding, and rubber powder bagging

.The output is

therefore recycled for good use in new applications which are able to substitute virgin materials. The rubber is

used in numerous

applications.

Application of End Products of Tire Recycling Machine

1. 8-20 mesh: it can be used for runway, road cushion, pad, lawn, elastic layer of pavement, and other sports venues.

2. 30-40 mesh: it can be used for producing reclaimed rubber and slab, and modified rubber powder, etc.

3. 40-60 mesh: it is known as fine powder, mainly used for filling rubber products, and plastic modification, etc.

4. 60-80 mesh: it is known as superfine powder, mainly used for automobile tire, rubber products, and building materials, etc.

1. 8-20 mesh: it can be used for runway, road cushion, pad, lawn, elastic layer of pavement, and other sports venues.

2. 30-40 mesh: it can be used for producing reclaimed rubber and slab, and modified rubber powder, etc.

3. 40-60 mesh: it is known as fine powder, mainly used for filling rubber products, and plastic modification, etc.

4. 60-80 mesh: it is known as superfine powder, mainly used for automobile tire, rubber products, and building materials, etc.

Products Description

Continuous waste tyre recycling plant

is equipped with

auto feeding system

&

auto discharge system

which in turn facilitates uninterrupted working of plant. Hence greater products yield can be obtained with minimum labor cost. This plant not only process 10-100 tons of waste tyre per day but can be also operated without any stop.

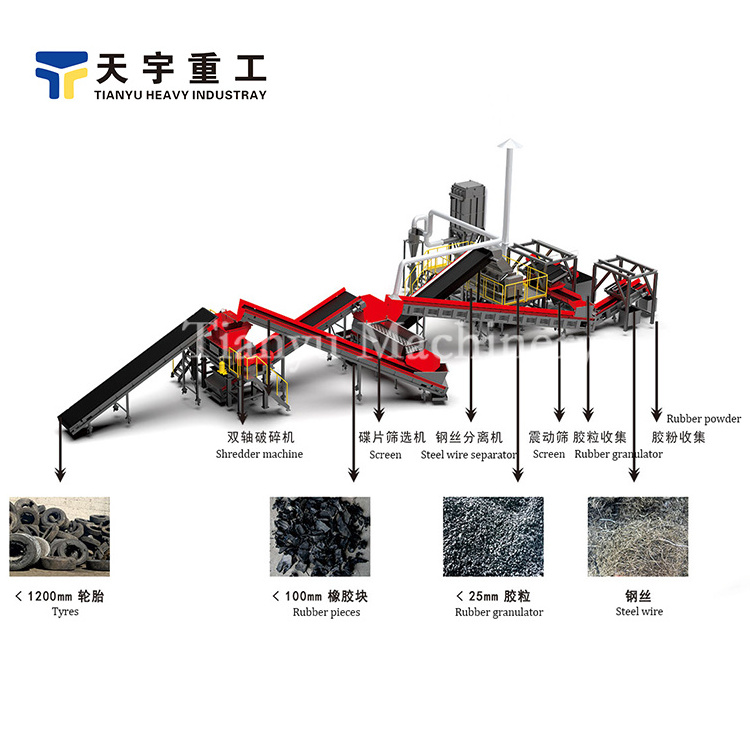

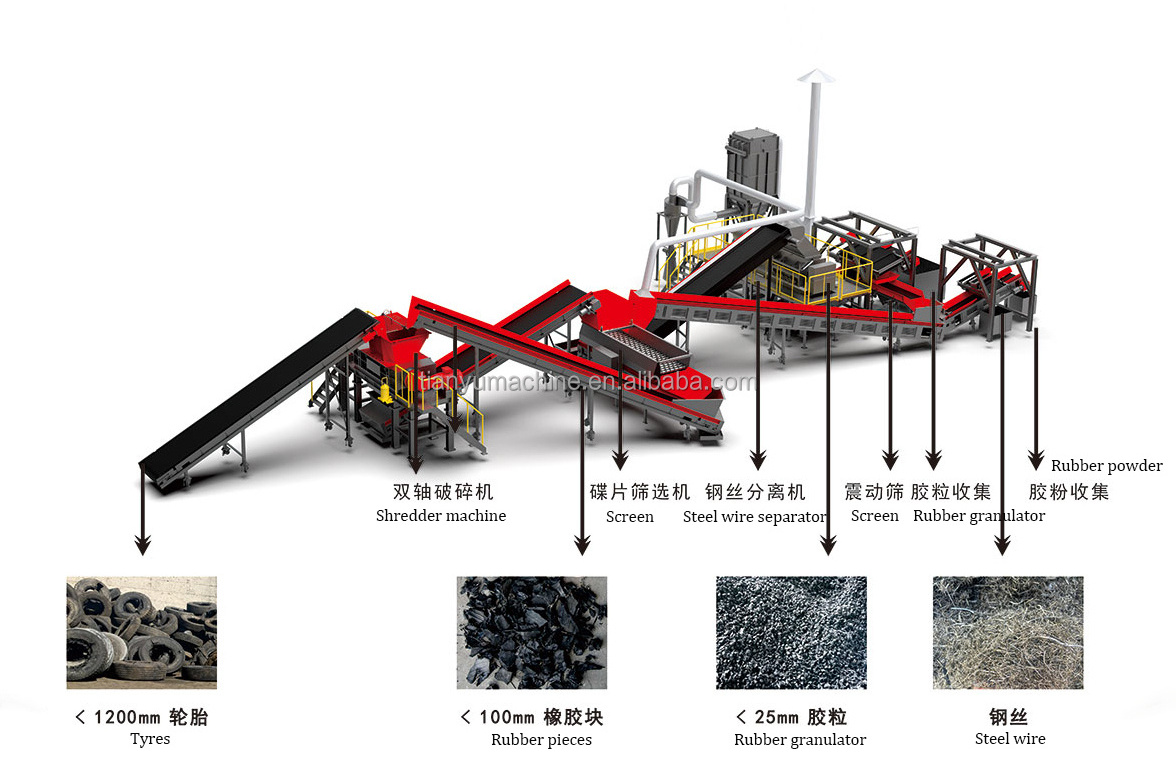

Technical Process

Full-auto tire recycling line is a complete production line for a series of waste tire recycling operations such as cutting, crushing, magnetic separation, fine crushing, grinding, and rubber powder bagging.

Technical Detail

ADVANTAGES

1. Complete automation of the ground rubber feeding.

2. Ability to grind to small sizes with high efficiency.

3. Self-cleaning buffer storage to load compounding line.

4. Ability to process sticky and soft rubbers.

5. Possibility to automatically align grinding capacity to extruder request.

1. Complete automation of the ground rubber feeding.

2. Ability to grind to small sizes with high efficiency.

3. Self-cleaning buffer storage to load compounding line.

4. Ability to process sticky and soft rubbers.

5. Possibility to automatically align grinding capacity to extruder request.

Technical Parameters

Case Requirements

|

Material:

|

Waste tires

|

|

Input size:

|

Diameter of tires ≤Φ1200mm

|

|

Output:

|

40-60mesh

|

|

Processing capacity:

|

Input: 1ton/hour;

|

|

Operation:

|

Full Automatic

|

|

Total Rated Power:

|

366kw; Power consumption: 366*0.7=256kwh

|

|

Workers needed

|

2-3 workers

|

|

Manufacturing time:

|

40 Working days after receiving the deposit

|

Installation Dimension

|

Name

|

Length

|

Width

|

Height

|

|

Unit(m)

|

45-50

|

8

|

6

|

Configuration

|

No.

|

Type

|

Name

|

Quantity (set)

|

Total Power((KW)

|

|

|

|

|

|

|

|

1

|

LSJ1200

|

Steel wire drawing machine

|

1

|

11

|

|

2

|

CSJ500

|

Belt conveyor

|

4

|

1.5

|

|

3

|

CSJ1300

|

Belt conveyor

|

1

|

3

|

|

4

|

SSJ1200

|

Double shaft shredder (rotary sieve)

|

1

|

75*2

|

|

|

|

|

|

|

|

5

|

CSJ1000

|

Belt conveyor

|

1

|

3

|

|

6

|

LC1000

|

Storage hopper

|

1

|

------

|

|

7

|

GS800

|

Steel wire separator (DC53 blades)

|

1

|

55

|

|

|

|

|

|

|

|

8

|

FSJ800

|

Rubber Granulator (DC53 blades)

|

1

|

45

|

|

|

|

|

|

|

|

9

|

CXJ300

|

Magnetic separator

|

2

|

0.75

|

|

10

|

ZDS2500

|

Vibrating screen

|

2

|

0.75

|

|

11

|

XWF1000

|

Fiber separator

|

1

|

9

|

|

12

|

XFJ260

|

Fine grinder

|

3

|

22

|

|

13

|

RDC1000

|

Dust collector

|

3

|

5.5

|

|

14

|

|

Water cooling system

|

1

|

|

|

15

|

|

Electric control cabinet

|

3

|

|

Customer Case

Technical Performance

Suitable for shredding materials, such as

Waste Tyre:Bicycle tyres, car tyres, train tyres.

Final product size can be customized.

FAQ

In order to better give you professional answers, when sending the inquiry, please describe your parameters or technical requirements (such as: processing materials, output size, capacity, etc.) and attach your contact information (such as phone number, e-mail, whatsapp, etc.)

1. How long is the product warranty period ?

A: the product warranty period is 24 months since shipping date.

2. I am a foreign customers, if the machine works wrong, how your company solved ?

A: We have professional engineers abroad , after receiving your request, we will solve your problems at first time.

3.Where can we buy the machine's parts?

A: Our company can provide machine`s parts for your any time .

4. Voltage in your country(price here based on 380v,50hz,3phase )?

A:220v/240v/380v/440v/480v or other customized available.

5.: Are you trading company or manufacturer?

A: We are manufactory , and we can give you lower price than those trade companies. Besides, customers from Alibaba can get a discount.

1. How long is the product warranty period ?

A: the product warranty period is 24 months since shipping date.

2. I am a foreign customers, if the machine works wrong, how your company solved ?

A: We have professional engineers abroad , after receiving your request, we will solve your problems at first time.

3.Where can we buy the machine's parts?

A: Our company can provide machine`s parts for your any time .

4. Voltage in your country(price here based on 380v,50hz,3phase )?

A:220v/240v/380v/440v/480v or other customized available.

5.: Are you trading company or manufacturer?

A: We are manufactory , and we can give you lower price than those trade companies. Besides, customers from Alibaba can get a discount.

Hot Searches