- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

27.12mhz

-

Welding Area:

-

1000*25MM

-

Dimensions:

-

1500*1000*2000

-

Usage:

-

Stretch Ceiling Welding,Tent Welding

-

Weight (KG):

-

900 KG

-

Power (kW):

-

12

-

Stretch ceiling High Frequency welding:

-

Tarpaulin high frequency welding machine

-

Tarpaulin/Canvas Stretch Ceiling:

-

High Frequency Welding Machine

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Showroom Location:

-

None

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Stretch Ceiling High Frequency Welding Machine

-

Voltage:

-

380V

-

Frequency:

-

27.12mhz

-

Welding Area:

-

1000*25MM

-

Dimensions:

-

1500*1000*2000

-

Usage:

-

Stretch Ceiling Welding,Tent Welding

-

Weight (KG):

-

900 KG

-

Power (kW):

-

12

-

Stretch ceiling High Frequency welding:

-

Tarpaulin high frequency welding machine

-

Tarpaulin/Canvas Stretch Ceiling:

-

High Frequency Welding Machine

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Showroom Location:

-

None

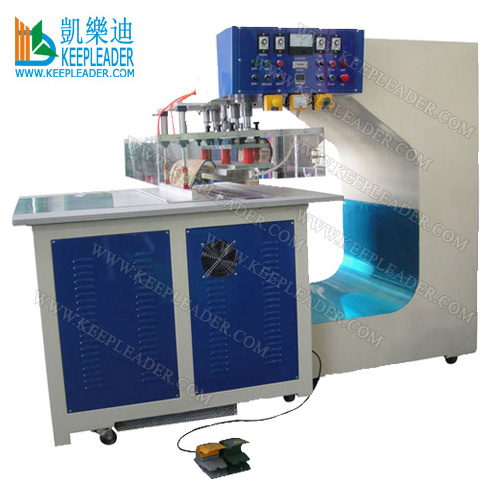

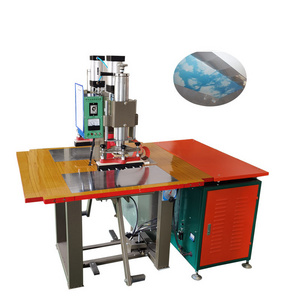

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine can customized welding size, material trough deth, configuration, and structure for each practical welding application

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine

|

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine |

|

|

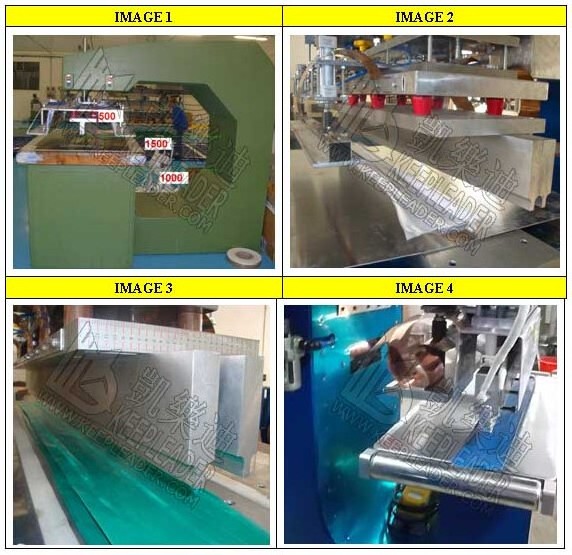

Mainly application |

|

|

Applied for tarpaulin, sun shading canvas, painting canvas, film curtain, canopy,Stretch ceiling,awning,truck cover,car tent, sunblind,Billboard, PVC film, PVC sheet and other around of this kind of membrane structure material welding or sealing |

|

|

Character |

|

|

High Q value oscillation tube the welding length is optional, maximum length:2000*25mm for 25kw The machine is G shape, have longer throat to hold the material High sensitive anti-sparkle device NL5557 to avoid damaging the mould. High quality imported apparatus European-model high frequency vibration box, more reliable and stable in output Laser position device for precision counterpoint Have boosting roller at two side for easy feeding materail Mounted five caster with four brakes Automatic thermostat to keep the temperature at best performance in welding High precision high frequency knob for visible control Low voltage control panel for safty purpose Anodized mould and tooling for longer life-span Top amounted cylinder for vertical pressing, which is more uniform pressure Foot pedal control and button control is optional Over current protection circuit to avoid burning the oscillation tube Power ranges 4kw up to 25kw for various welding length |

|

|

Technique specifications |

|

|

Model |

KLR-12KW-SN |

|

Power |

12kW |

|

Power supply |

220V/380V 50/60HZ |

|

Frequency |

27.12MHZ |

|

Input power |

20KVA |

|

Rectifier |

SILICON DIODE |

|

Oscillation tube |

E3130 |

|

Max pressure |

1000kg |

|

Gap of electrodes |

200MM |

|

Moving distance of active horn |

170MM |

|

Size of upper electrode |

1000*80MM |

|

Size of down electrode |

1200*120MM |

|

Welding time |

0~10S Adjustable |

|

Net weight |

900KG |

|

Overall dimension |

1500*1000*2000 |

MFR: KEEPLEADER™ have modified and designed PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Standard equipment:

|

Name |

Origin |

Brand |

|

Air driven components |

Taiwan |

Airtac |

|

AC contactor |

Korean |

LG |

|

Relay |

Japan |

Omron |

|

Electron Tube |

Japan |

Toshiba |

|

Time controller |

Taiwan |

CKC |

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine has features of #1: trough depth customized #2: Dual lines in one process, or single line seam sealing #3: adjustable welding space in two lines #4: Heating device equipped as demanding #5: impelling rolls at two side of bench

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

Service process at KEEPLEADER™

the clients offer information of the workpieces being welded (eg: picture, materials, sizes, requirements, etc) if have samples, it’s better to send KEEPLEADER™ some sample to perform the welding test, if can be welded, we provide offer sheet, once confirmed, sing a contract, the clients paid the deposit, KEEPLEADER™ start equipment building, after passing the acceptance, and receive the balance payment, KEEPLEADER™ delivery the device to clients

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine is packed in plywood case, which is fumigation free for international sea transportation

After purchasing at KEEPLEADER™ is first step of our after-service, all of machines at KEEPLEADER™ has one year guarantee, we provide free samples for defected parts to do replacement except for human damage, under information for your notice

01: KEEPLEADER™ always posts the new technical file in our homepage that can help our client in new technical information of machines’ design, character, application, operation, maintenance,

and related, KEEPLEADER™ also welcome our clients feed back the machines’ working condition that can get one to one service

02: If the machine you purchased has any defects, please contact sales representative at KEEPLEADER™, we will assign our experienced engineer analyze your case and provide technical support, in case of damaged parts that cannot repair, KEEPLEADER™ will provide a new parts to replace the defect

03: For any replacement and maintenance, KEEPLEADER™ has user manual and training video

04: KEEPLEADER™ can go to oversea for on-site training

05: KEEPLEADER™ can provide electric diagram if in need

06: PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine has "user manual" and "tutorial video"

PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine is molecular bonding in field of electronic oscillation heated, only applied in the sealing area and quick cooling down without disformation around for molecular material sealing connection, whkch is widely used in producing inflatable product, sun shading, tent, truck cover, pool liner, banner, billboard

Our company aim to provide world wide brand of PVC Tent/Tarpaulin/Canvas Stretch Ceiling High Frequency Welding Machine , it is our eternal pursuit for exchange our sincerity, hard work and sweat for customer satisfaction, welcome your inquires, we, keepleader firmly grasps the opportunity of rapid economic development, adhere to the business philosophy of “forging ahead, surpassing” respecting talents, focusing on products and pursuing higher goals based on unremitting efforts

Attn: Ms Helen / E-mail: sales (at) keepleader.com / Website: www.keepleader.com / www.hfwelds.com