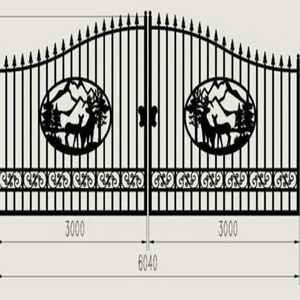

Our designer team designs

the reliefs on the surface of cast aluminum gates or railings in detail according to the styles and dimensions provided by the

customers, So that the customers can know the 3D effect of his products more clearly.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Hua Art

-

Model Number:

-

wrought iron door

-

Product name:

-

Wrought Iron Gate

-

Material:

-

Wrought iron,steel,aluminum

-

Color:

-

Customized Color

-

Keywords:

-

Wrought Iron Entry Door

-

Type:

-

Double Door

-

Function:

-

Corrosion-resistance

-

Name:

-

Main Gate Designs

-

Surface treatment:

-

Galvanized+Powder Coated

-

Feature:

-

Durable

-

Size:

-

Customized Size

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, Others

-

Application:

-

Villa, Garden, Courtyard, Apartment, Entry

-

Design Style:

-

Modern

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Hua Art

-

Model Number:

-

wrought iron door

-

Product name:

-

Wrought Iron Gate

-

Material:

-

Wrought iron,steel,aluminum

-

Color:

-

Customized Color

-

Keywords:

-

Wrought Iron Entry Door

-

Type:

-

Double Door

-

Function:

-

Corrosion-resistance

-

Name:

-

Main Gate Designs

-

Surface treatment:

-

Galvanized+Powder Coated

-

Feature:

-

Durable

-

Size:

-

Customized Size

Products Description

|

Product name

|

Wrought Iron Gate

|

|

Color

|

Black, Brown, Gold, Others

|

|

Size

|

W8'xH8' / W10'xH8'/ W12'xH8'/ Any size can be customized

|

|

Material

|

Wrought iron, Steel, Aluminum

|

|

Accessories

|

Special security lock, Handle,Latch, viewer if necessary

|

|

Door leaf thickness

|

1-1/5'' (36mm) / 2'' (50mm)/ Any thickness can be customized

|

|

Door panel Design

|

Any relief design can be made on both sides

|

|

Drawing design

|

We can provide 3D design

|

|

Surface finish

|

Baked coating/powder coating

|

|

Anti-rusting Way

|

Never rusted

|

|

Delivery Time

|

Within 35-45 working days after your payment

|

|

Payment Term

|

T/T, 50% deposit, and balance paid before delivery

|

|

OEM&ODM

|

Service available

|

Details Images

1.Professional relief design

2.Professional mold CNC machining center

Our designer will input the designed relief drawings into our mold processing center and the mold will be carved out according to

the design drawings.

the design drawings.

3. Electric furnace melting

Put the raw material standard aluminum ingot "Material: A102" into an electric furnace and melt it into motten aluminum after

being subjected to a high temperature of 800 degrees

being subjected to a high temperature of 800 degrees

4. Installation mold

Install the mould on the workbench of large vacuum casting equipment.

5.Product mold modeling

Put the carved mold into the large vacuum casting equipment to completely cover the mold with sand, and use the vacuum casting

principle to completely solidify the sand.

principle to completely solidify the sand.

6. Product mold modeling

Through the principle of vacuum casting,the sand has been solidified into the design of the product and the mold assembly is completed through the upper mold and the lower mold.

7. Cast aluminum pouring

Pour molten aluminum (800 degrees) into the mold. The molten aluminum will soon be poured into every part of the product and

slowly solidify.

slowly solidify.

8. Demold

After about 40 minutes after the aluminum water in the mold, the product has been completely formed and solidified.The mold can be

opened to take the product we need.

opened to take the product we need.

9. Cast aluminum product thickness

Among the gates we are currently using.The normal thickness is 36mm (1 1/4") 50mm (2"), and any thickness can be customized.

10 .

Vacuum cast aluminum surface details

At present, only the vacuum casting aluminum method can achieve the surface relief of the product with delicate edges and corners

and no pores. The maximum size of our single product can be 2mx3m.

and no pores. The maximum size of our single product can be 2mx3m.

.

Related products

Hot Searches