- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

220V/380V

-

Power:

-

300KW

-

Dimension(L*W*H):

-

Configuration

-

Weight:

-

5000 kg

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Name:

-

Equipment for waste recycling paper

-

Raw material:

-

Waste box,waste paper

-

Finished Products:

-

Corrugated paper,kraft paper,etc

-

Basis weight:

-

80-200g/m2

-

Trimmed width(mm):

-

2500

-

Working speed:

-

60-100m/min

-

Design speed:

-

140m/min

-

Dynamic balance speed:

-

250m/min

-

Experience:

-

Since 1980

Quick Details

-

Production Capacity:

-

30-40t/d

-

Product Type:

-

Corrugated paper,kraft paper,etc

-

Processing Type:

-

Paper recycling machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

220V/380V

-

Power:

-

300KW

-

Dimension(L*W*H):

-

Configuration

-

Weight:

-

5000 kg

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Name:

-

Equipment for waste recycling paper

-

Raw material:

-

Waste box,waste paper

-

Finished Products:

-

Corrugated paper,kraft paper,etc

-

Basis weight:

-

80-200g/m2

-

Trimmed width(mm):

-

2500

-

Working speed:

-

60-100m/min

-

Design speed:

-

140m/min

-

Dynamic balance speed:

-

250m/min

-

Experience:

-

Since 1980

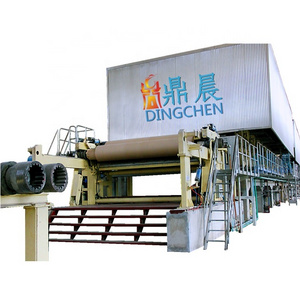

Paper Producing Plant Equipment For Waste Recycling Paper 30-40T/D

This paper making machine is designed for high quality kraft paper making,fluting paper making,etc.Our this machine adopts first grade auxiliries and most advanced technics in China. Paper from this paper machine is in high grade , smooth and well selling.

We can provide whole kraft paper production line , including pulp &paper making equipment and paper machine spare parts. All the equipment have international certifications.

1.Main technical data

Main product: kraft paper, corrugated paper, fluting paper

Raw material: Recycled paper, OCC,etc

Basic weight: 80-200g/m2

Trimmed Width: 2500mm

Working speed: 60-100m/min

Design speed: 14 0m/min

Production capacity: 30-40t/d

Dynamic balance speed : 250m/min

Wire width : 2900mm

2. Requirement of technology

Dryness after wire section: ≥20%

Dryness after press section: ≥45%

Dryness of entering sizing machine: ≥92%

Dryness after sizing machine: ≥65%

Dryness of finished paper: 92%

Sizing concentration: 8%

Sizing amount: 2.5~3 g/ m2 each face

Lateral shrinkage: ≤5%

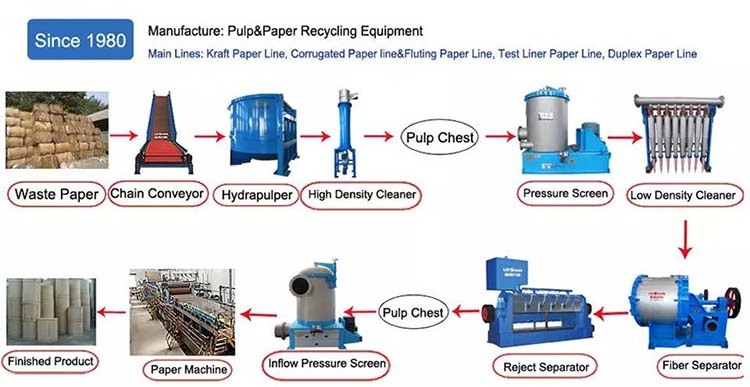

3. Paper making process:

This paper machine mainly use waste paper and carton as raw material.

The waste paper is pulping by hydraulic pulper ,then passed through the processed of high density cleaner,fiber separater,pressure screen,light impurity separator, multi-disc concentration,low density cleaner,disc refiner,then the finished pulp feed into the paper making machine ,press dehydration, dryer drying, paper rolling, rewinding and other processes, to produce recycled kraft paper.

Raw materials (waste paper)——chain conveyor——pulper——hign density cleaner——pressure screen——fiber separator——reject separator ——low density cleaner——inflow pressure screen——paper making machine——the big finished jumbo roll paper

4. Main structure

The machine consists of headbox, fourdrinier wire forming, press section, drying section, gas

hood section, sizing machine, calender, mechanical drive section, compressed air system,

lubrication system, hydra u lic pressure system, basic section, reeling machine. Paper machine

scheme drawing shows the main arrangement.

Our paper machine adopts most advanced technicas and is equipped with best quality accessories , so paper produced by our machine has high folding endurance, is well-selling and profitable.

5. Final paper rolls in rewinding part