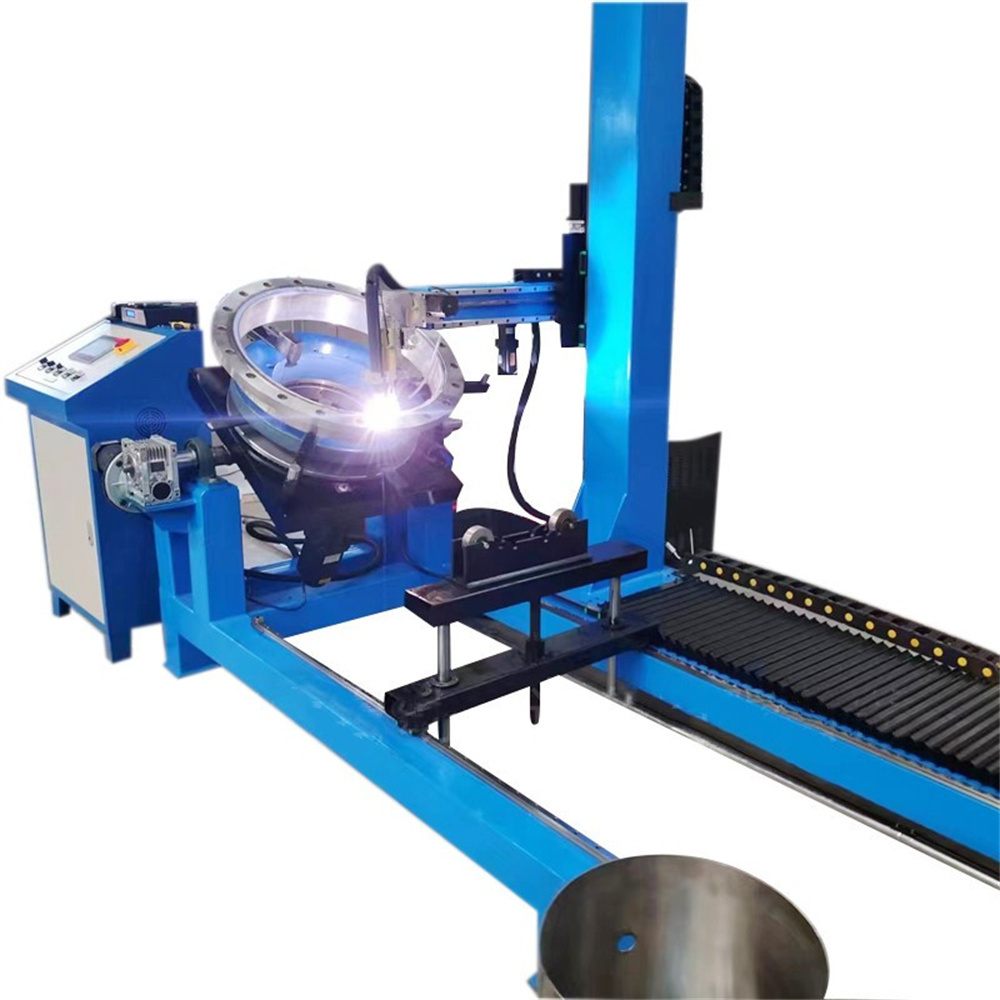

Structural features

The machine tool is composed of a bed, a power drive mechanism, a fixture, an intermediate support mechanism, a welding gun support and, a pneumatic lifting and fine-tuning regulator, a tail top, and a PLCcontrolsystem. It adopts a lower bed, which is convenient for workpiece loading and unloading, and has good stability. Place the assembled workpiece on the fixture and tighten it with pneumatic jacking; A series of welding processes can be carried out by adjusting the included angle between the welding gun and the horizontalrotation line according to the welding process. After welding, the welding torch will return automatically, the pneumatic clamping will be loosened at the same time, and the workpiece can be removed manually. This control centeris controlled by PLC.

- Product Details

- {{item.text}}

Quick Details

-

Welding Mode:

-

Crosswise

-

Welding Diameter:

-

10-100cm

-

Dimensions:

-

1600*1500*1900mm

-

Use:

-

Seam Welding

-

Voltage:

-

380V

-

Weight (KG):

-

480 KG

-

Power (kW):

-

25

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Lucosy

-

Forming Time:

-

0.5S

-

Welding Mode:

-

Crosswise

-

Welding Diameter:

-

10-100cm

-

Dimensions:

-

1600*1500*1900mm

-

Use:

-

Seam Welding

-

Voltage:

-

380V

-

Weight (KG):

-

480 KG

-

Power (kW):

-

25

FEATURES AT A GLANCE

Customized

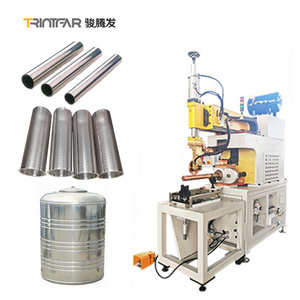

Automatic Straight Longitudinal Seam Welder Tank Circular Seam Welding Machine

Horizontal Linear Seam Integrated welding machine is an automatic welding system designed for double girth and straightseamwelding. The system is composed of welding machine tool, welding powersupply, wire feeding mechanism, PLCcontrolsystem, control cabinet, etc; It issuitable for circumferentialseam welding of workpiece and TIG argon arc welding method, with beautiful appearance.

Product Overview

PRODUCT SPECIFICATIONS

|

Part name

|

Qty

|

Automatic gun feeding mechanism

|

1

|

|

|

Bed

|

1

|

Control system, PLC

|

1

|

|

|

Main drive step transmission mechanism device

|

1

|

Workpiece rotating assembly

|

1

|

|

|

Workpiece positioning, clamping and fixing device

|

1

|

Argon arc welding automatic wire feeder

|

1

|

|

|

Welding gun fixing mechanism

|

1

|

Arc length tracker

|

1

|

|

|

Three dimensional adjustment mechanism of welding torch position

|

1

|

General 350 two guarantee welding machine

|

1

|

|

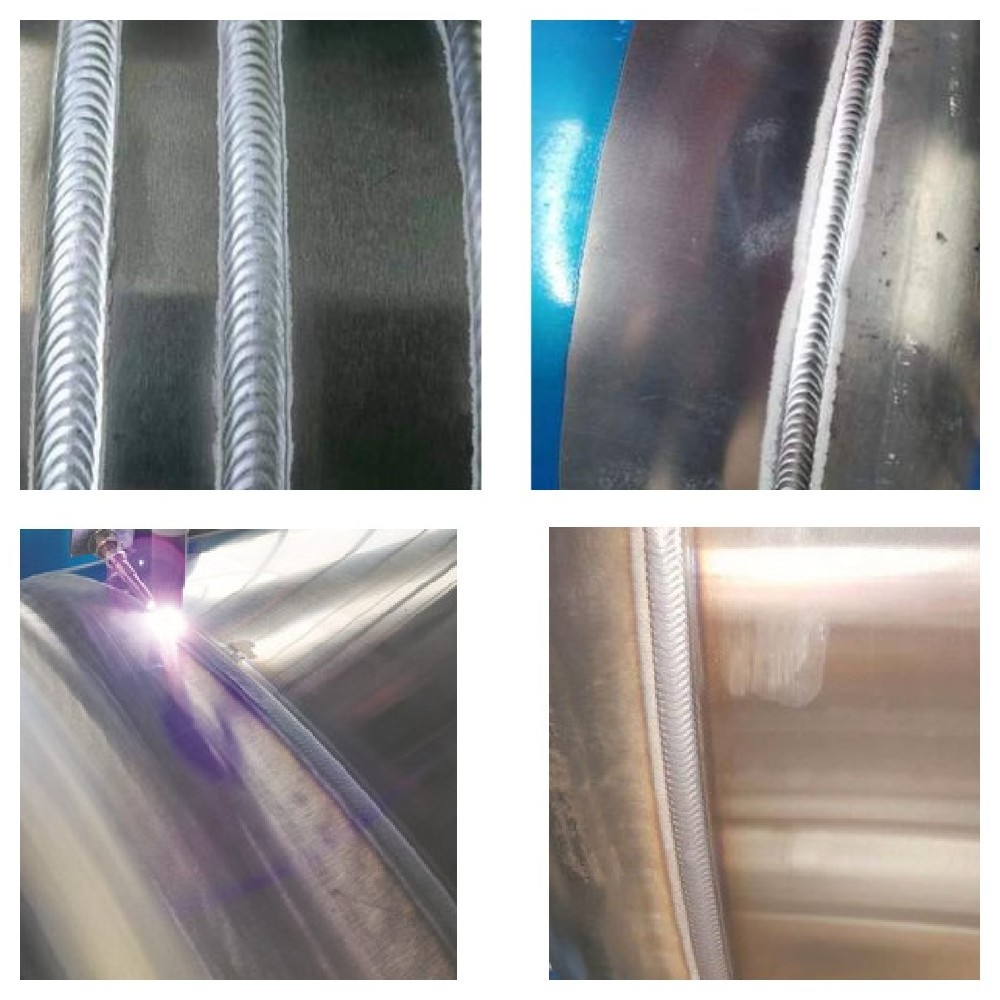

Welding Samples

Tank

Cylinder

Pipe

Successful Project

Project in India

Project in Malaysia

Project in Brazil

Hot Searches