- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/440V

-

Power:

-

4-132kw

-

Dimension(L*W*H):

-

According Green Sand Foundry Molding Line

-

Weight (KG):

-

5000

-

Product name:

-

rotor type sand mixer

-

Application:

-

green sand mixer

-

After-sales Service Provided:

-

Free spare parts

-

Foundry Machine:

-

Foundry Sand Mixer Muller

-

Technology:

-

Green Sand Casting Technology

-

Usage:

-

Foundry Castings Production

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

green sand mixer

-

Brand Name:

-

TZZJ

-

Voltage:

-

220V/380V/440V

-

Power:

-

4-132kw

-

Dimension(L*W*H):

-

According Green Sand Foundry Molding Line

-

Weight (KG):

-

5000

-

Product name:

-

rotor type sand mixer

-

Application:

-

green sand mixer

-

After-sales Service Provided:

-

Free spare parts

-

Foundry Machine:

-

Foundry Sand Mixer Muller

-

Technology:

-

Green Sand Casting Technology

-

Usage:

-

Foundry Castings Production

Products Description

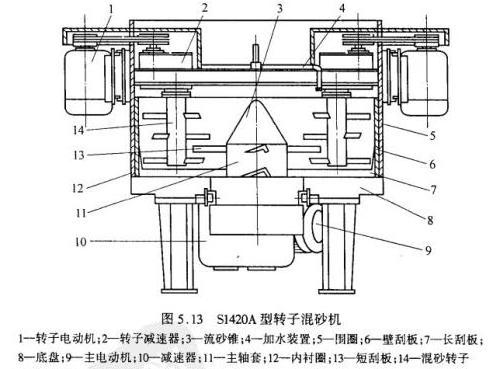

S14 series fixed rotor sand mixer use:

The rotor sand mixer

is mainly used for mixing sand in foundry workshops. It can be used to mix single sand for machine modeling, dry film sand, self-hardening sand, face sand and back sand, as well as glass, ceramics and refractory. Materials and other industries to mix all kinds of powder and granular materials.

Features of S14 series fixed rotor sand mixer:

1) The best cooperation between low-speed scraper and medium-speed rotor, large amount of sand mixing, strong mixing ability, good overall performance of molding sand.

2) New materials such as diabase cast stone, tungsten carbide surfacing, No. 2 filler, etc., have greatly improved the life of wearing parts.

3) Hydraulic coupling, alloy steel gear, No. 1 packing, lubrication control machine, ensure that the transmission system is stable and reliable, and can start under load.

4) The latest rotary discharge door opens flexibly and works reliably.

5) The symmetrically opened maintenance door greatly facilitates maintenance and cleaning.

6) The steel structure base makes the machine installation very convenient.

Uses

The rotor sand mixer

Mainly used for casting workshop sand mixed, either mixed single machine molding sand can be mixed dry film sand, hard sand, the sand surface and core sand, glass, ceramics, refractories, etc. Can also be usedindustry mixed a variety of powder, granular materials.

|

Model

|

Name

|

Disk diameter (mm)

|

First feeding amount (kg)

|

Productivity (t / h)

|

Power of main motor (Kw)

|

quality

|

|

S1410A

|

Rotor sand mixer

|

Ф1000

|

200

|

5

|

4

|

1000

|

|

S1412

|

Rotor sand mixer

|

Ф1200

|

330

|

6-8

|

7.5

|

2800

|

|

S1416A

|

Rotor sand mixer

|

Ф1600

|

660

|

12-18

|

15

|

3800

|

|

S1418

|

Rotor sand mixer

|

Ф1800

|

800

|

15-25

|

22

|

4500

|

|

S1420J

|

Rotor sand mixer

|

Ф2000

|

1000-1350

|

20-28

|

30

|

6500

|

|

S1420D

|

Rotor sand mixer

|

Ф2000

|

1200-1400

|

25-30

|

37

|

7000

|

|

S1420K

|

Rotor sand mixer

|

Ф2000

|

1350-1600

|

32-40

|

55

|

9500

|

|

S1422

|

Rotor sand mixer

|

Ф2240

|

1500-1700

|

38-45

|

55

|

11800

|

|

S1422E

|

Rotor sand mixer

|

Ф2240

|

1600-1900

|

47-55

|

75

|

12600

|

|

S1425

|

Rotor sand mixer

|

Ф2500

|

2200-2500

|

60-75

|

75

|

15000

|

|

S1425D

|

Rotor sand mixer

|

Ф2500

|

2300-2800

|

69-80

|

90

|

15500

|

|

S1425F

|

Rotor sand mixer

|

Ф2500

|

2500-3000

|

75-96

|

110

|

16500

|

|

S1428

|

Rotor sand mixer

|

Ф2800

|

4000-5000

|

120-150

|

132

|

22800

|

Product Show

Recommend Products

Packing&Shipping

Hot Searches