- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

insulating fire brick

-

Brand Name:

-

LUYANG, LUYANG

-

Bulk density(g/cm3):

-

06/08/0.9/1/1.1

-

temperature classification ,℃:

-

1300/1400/1500/1550/1600

-

Cold crushing strength,Mpa ≥:

-

1.2/1.8/2.5/3.3/3.5

-

Permanent Linear Change (% ≤)x24hrs:

-

0.6/0.6/0.8/0.9/0.9

-

Al2O3% (≥):

-

42/56/67/73/79

-

SiO2% (≥):

-

51/41/30/24/20

-

Fe2O3% (≤):

-

1/0.8/0.7/0.7/0.5

-

Product name:

-

Mullite Insulating Brick

-

Usage:

-

Fire Resistance Place

Quick Details

-

SiO2 Content (%):

-

55-24

-

Al2O3 Content (%):

-

42-73

-

MgO Content (%):

-

-

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

insulating fire brick

-

Brand Name:

-

LUYANG, LUYANG

-

Bulk density(g/cm3):

-

06/08/0.9/1/1.1

-

temperature classification ,℃:

-

1300/1400/1500/1550/1600

-

Cold crushing strength,Mpa ≥:

-

1.2/1.8/2.5/3.3/3.5

-

Permanent Linear Change (% ≤)x24hrs:

-

0.6/0.6/0.8/0.9/0.9

-

Al2O3% (≥):

-

42/56/67/73/79

-

SiO2% (≥):

-

51/41/30/24/20

-

Fe2O3% (≤):

-

1/0.8/0.7/0.7/0.5

-

Product name:

-

Mullite Insulating Brick

-

Usage:

-

Fire Resistance Place

Product Description

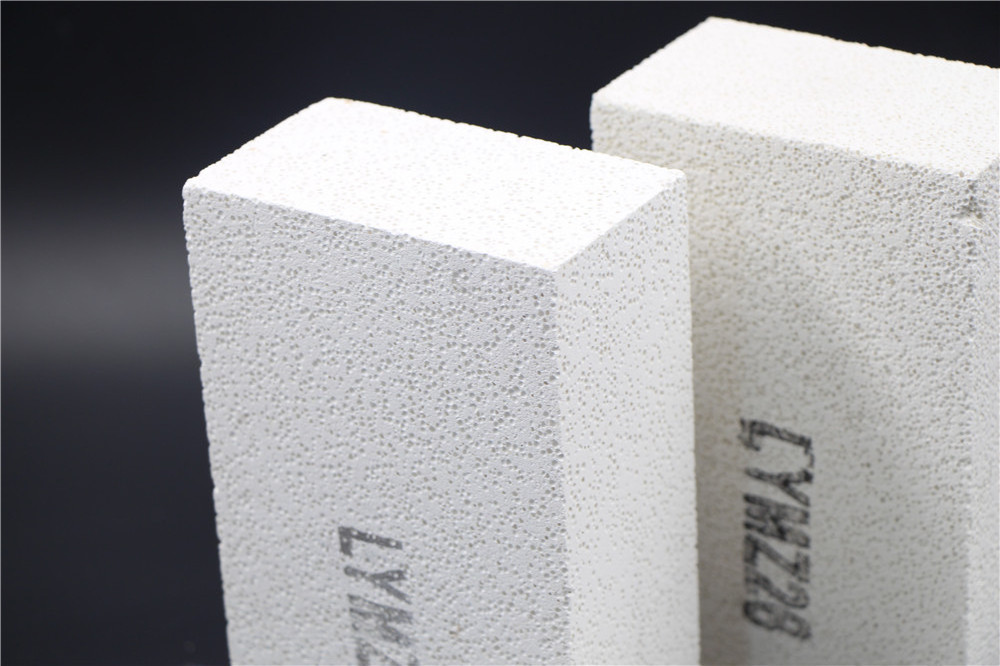

INSULATING FIREBRICK

Luyang Insulating Firebrick is made from high-purity refractory powder and organic fillers which burn out during manufacture to

give a uniform and controlled pore sture. The brick is compressed in vacuum and sintered under high temperature. Luyang Insulating

Firebrick is widely used as hot face refractory lining or back-up insulation in various kinds of industrial furnaces.

Features

Excellent thermal shock resistance

Accurate and customized dimension

High crushing strength

Low thermal conductivity

Low heat storage

Typical Applications

Metallurgy industry

Petrochemical industry

Ceramics industry

Aluminum industry

Glass industry

Luyang Insulating Firebrick is made from high-purity refractory powder and organic fillers which burn out during manufacture to

give a uniform and controlled pore sture. The brick is compressed in vacuum and sintered under high temperature. Luyang Insulating

Firebrick is widely used as hot face refractory lining or back-up insulation in various kinds of industrial furnaces.

Features

Excellent thermal shock resistance

Accurate and customized dimension

High crushing strength

Low thermal conductivity

Low heat storage

Typical Applications

Metallurgy industry

Petrochemical industry

Ceramics industry

Aluminum industry

Glass industry

|

Material

|

Luyang light weight insulating firebrick

|

|

Brand

|

LUYANG

|

|

Size

|

Standard sizing: 230 x 114 x 65 mm , Special size and OEM Service also provide !

|

|

Shape

|

Straight Brick, special-shaped brick, checher brick, trapezoidal brick, Bricks with taper, arch brick, skew brick, ect.

|

Specification

|

Description

|

GRADE 23 BRICK

|

GRADE 26 BRICK

|

GRADE 28 BRICK

|

GRADE 30 BRICK

|

||||

|

Classification Temperature (℃ )

|

1300

|

1400

|

1500

|

1550

|

||||

|

Chemical Composition (%)

|

|

|

|

|

||||

|

Al2O3

|

40

|

56

|

67

|

73

|

||||

|

SiO2

|

51

|

41

|

30

|

24

|

||||

|

Fe2O3

|

≤1.0

|

≤0.8

|

≤0.7

|

≤0.6

|

||||

|

Density (kg/m³)

|

600

|

800

|

900

|

1000

|

||||

|

Modulus of Rupture (MPa)

|

0.9

|

1.5

|

1.8

|

2.0

|

||||

|

Cold Crushing Strength (MPa)

|

1.2

|

2.4

|

2.6

|

3.0

|

||||

|

Permanent Linear Change (%)

|

1230℃ x 24h ≤0.3

|

1400℃ x 24h ≤0.6

|

1510℃ x 24h ≤0.7

|

1620℃ x 24h ≤0.9

|

||||

|

Thermal Conductivity (W/m·K)

|

|

|

|

|

||||

|

200℃

|

0.15

|

0.23

|

0.27

|

0.28

|

||||

|

350℃

|

0.18

|

0.24

|

0.30

|

0.35

|

||||

|

400℃

|

0.19

|

0.25

|

0.33

|

0.38

|

||||

|

600℃

|

0.23

|

0.27

|

0.38

|

0.40

|

||||

Application

|

Iron & steel making industry

|

Blast furnace, hot blast furnace(stove), pellet shaft furnace, hot metal ladle, steel ladle, tundish, eating furnace, soaking pit furnace, heat treatment furnace, refining furnace, reheating furnace, metal mixter furnace, cupola furnace etc thermal technology equipment.

|

|

Non-ferrous Metal industry

|

Smelting furnace, reverberatory furnace etc.

|

|

Building materials industry

|

Cement kiln, glass kiln, ceramic kiln, lime kilns, kiln car, tunnel kiln, rotary kiln.

|

|

Energy&Incineration

|

Coke oven, general boiler, power generation boiler, circulating fluidized bed boiler, electric furnace, carbon roasting furnace, waste incinerators

|

|

Others

|

Petrochemical industry furnace, Pizza oven

|

Hot Searches