- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

18.5KW

-

Dimension(L*W*H):

-

6050*4080*3320

-

Weight (KG):

-

1212

-

Brand:

-

Coloreeze

-

Powder Coating Booth:

-

Powder Coating Line Spray Booth

-

Fire Extinguisher Cylinder Painting:

-

Powder coating line for panel

-

3A Automatic Powder Spray:

-

Fire Extinguisher Cylinder Powder Painting Line

-

POWDER COATING SPRAY BOOTH:

-

POWDER COATING CYCLONE BOOTH

-

POWDER COATING BOOTH SYSTEM:

-

PAINT BOOTH CHINA

-

POWDER COATING LINE FOR PANEL:

-

HORIZONTAL PRODUCTION LINE FOR ALUMINUM

-

POWDER PAINTING BOOTH:

-

POWDER COATING BOOTH FOR MICRO OVEN BODY SHELL

-

POWDER COATING MACHINE:

-

POWDER COATING OVEN

Quick Details

-

Machine Type:

-

new, Spray Booths

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Coloreeze

-

Voltage:

-

220V

-

Power:

-

18.5KW

-

Dimension(L*W*H):

-

6050*4080*3320

-

Weight (KG):

-

1212

-

Brand:

-

Coloreeze

-

Powder Coating Booth:

-

Powder Coating Line Spray Booth

-

Fire Extinguisher Cylinder Painting:

-

Powder coating line for panel

-

3A Automatic Powder Spray:

-

Fire Extinguisher Cylinder Powder Painting Line

-

POWDER COATING SPRAY BOOTH:

-

POWDER COATING CYCLONE BOOTH

-

POWDER COATING BOOTH SYSTEM:

-

PAINT BOOTH CHINA

-

POWDER COATING LINE FOR PANEL:

-

HORIZONTAL PRODUCTION LINE FOR ALUMINUM

-

POWDER PAINTING BOOTH:

-

POWDER COATING BOOTH FOR MICRO OVEN BODY SHELL

-

POWDER COATING MACHINE:

-

POWDER COATING OVEN

Detailed Images

Specification

| 1. [ Name ] |

| Automatic production Powder Coating Line |

| 2. [ Product introduction ] |

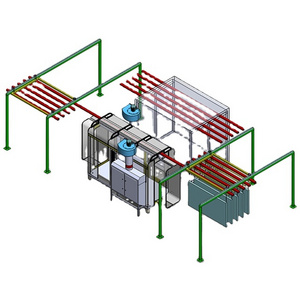

| Production powder coating line unit consists of automatic electrostatic powder spray gun, Single or double spray station automatic powder spray booth, and powder curing oven. It can be flexibly combined to meet your workpiece powder coating needs. |

| 3. [ Application range ] |

| V arious metal products, stainless steel products, a luminum profiles, Metal furniture and components etc. surface powder coating. |

| 4. [ Advantages and characteristics ] |

| The equipment investment is small, meeting the powder coating requirements of low-output workpieces. |

| Low production costs, saving powder and saving energy consumption. |

| High flexibility of w orkpiece suspension, spraying, curing, rotating and transferring etc. |

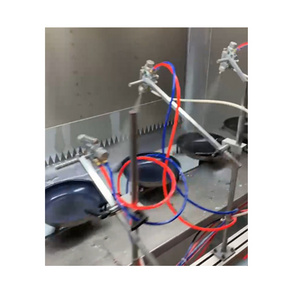

| The spray gun selects special type suitable for complex and irregular workpieces, which is easy to operate and has good spraying effect. |

| The spray booth and curing oven can be customized according to the requirements of types, sizes etc. |

| 5. [ Specifications ] |

| Contact us for a complete solution . |

| 1 Powder Coating Gun Selection: |

| Powder Coating Gun CLE-2FM |

| Powder Coating Gun MA3300D |

| Powder Coating Gun P9S |

| Powder Coating Gun NCLE-2FM |

| 2. Custom Spray Booth: |

| Customized spray booth overall size, detailed work area length, width and height; workpiece suspension. |

| 3. Custom Curing Oven : |

| Curing Oven size , detailed work area length, width and height ; |

| Heating energy , Gas Diesel or Electric |

| Hanging rail suspension or workpiece trolley ; |

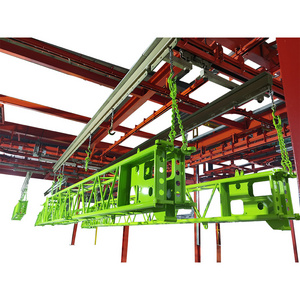

| 6 [Conveyor and Control System] |

| Suspension conveyor system is the key equipment for the spraying production line. The quality is directly affecting the normal operation of the production. |

| Control system: All kinds of components shall be marked at their fixed positions, and wire numbers shall be provided at both ends of each type of wire, and the sign and line number shall be the same as the schematic diagram. |

| The layout of the circuit in the electric control cabinet is neat and reasonable, and the arrangement of components is arranged according to the function. |

| The motor adopts circuit design with overload protection, short circuit protection and phase failure protection. |

| 6. [ Related Products ] |

| Full Automatic powder coating line |

| Linear traverse powder coating system |

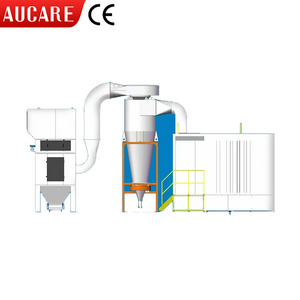

| Powder coating big cyclone spray booth |

| Powder coating curing oven |

Packaging

How to select!

How to select suitable powder coating booth?

Hot Searches