- Product Details

- {{item.text}}

Quick Details

-

Board Size:

-

OEM

-

Model Number:

-

Wonderful PCB&PCBA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WDF

-

Copper Thickness:

-

1OZ

-

Min. Hole Size:

-

0.2MM

-

Min. Line Width:

-

0.35/0.4MM

-

Min. Line Spacing:

-

0.4MM

-

Surface Finishing:

-

ENIG

-

Product name:

-

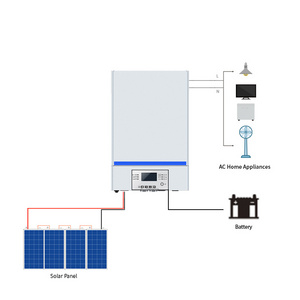

solar circuit board

-

Layer count:

-

1 to 28 layers

-

Material type:

-

FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers

-

Surface finishing:

-

HASL / HASL lead free, Immersion Silver/Gold, OSP, Gold plating

-

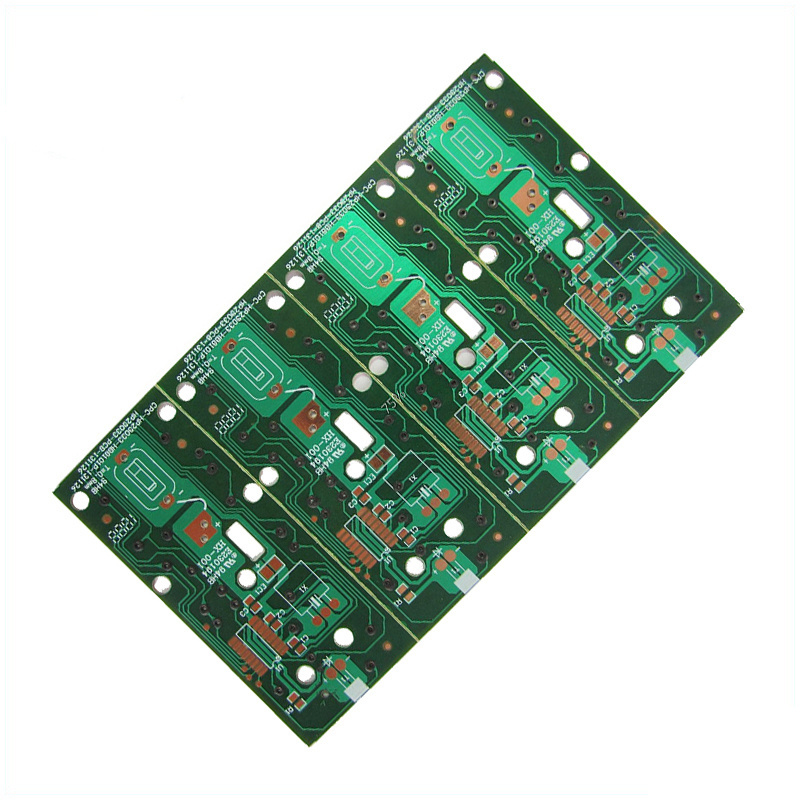

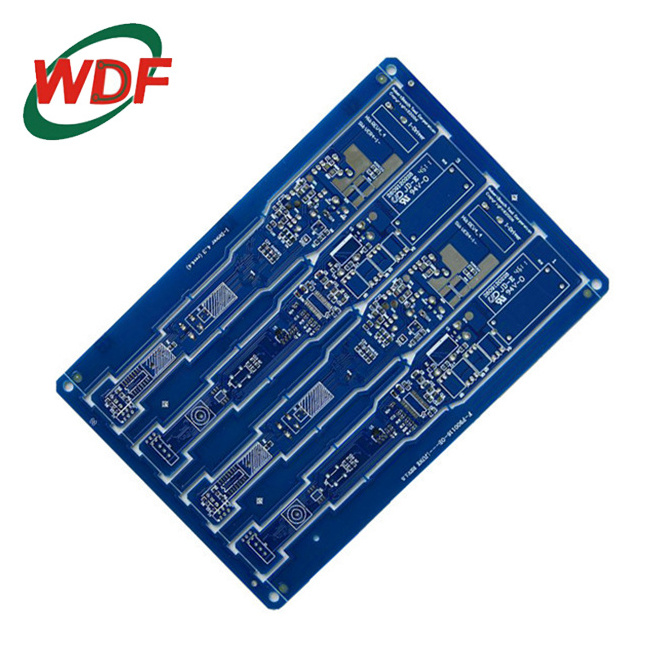

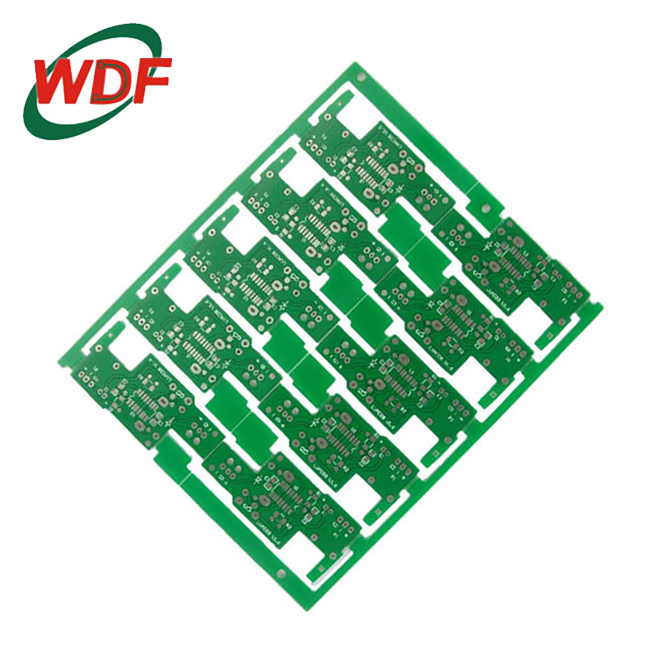

Solder Mask Color:

-

Green/Yellow/Black/White/Red/Blue

-

Profiling:

-

Punching, Routing, V-CUT, Beveling

-

Service:

-

OEM services provided

-

Certificate:

-

ROHS, ISO9001-2000, ISO14001

-

Price:

-

Factory direct price

-

Application:

-

Communications, automobile, consumer electronics

Quick Details

-

Number of Layers:

-

Other

-

Base Material:

-

FR-4

-

Board Thickness:

-

1.6MM

-

Board Size:

-

OEM

-

Model Number:

-

Wonderful PCB&PCBA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WDF

-

Copper Thickness:

-

1OZ

-

Min. Hole Size:

-

0.2MM

-

Min. Line Width:

-

0.35/0.4MM

-

Min. Line Spacing:

-

0.4MM

-

Surface Finishing:

-

ENIG

-

Product name:

-

solar circuit board

-

Layer count:

-

1 to 28 layers

-

Material type:

-

FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers

-

Surface finishing:

-

HASL / HASL lead free, Immersion Silver/Gold, OSP, Gold plating

-

Solder Mask Color:

-

Green/Yellow/Black/White/Red/Blue

-

Profiling:

-

Punching, Routing, V-CUT, Beveling

-

Service:

-

OEM services provided

-

Certificate:

-

ROHS, ISO9001-2000, ISO14001

-

Price:

-

Factory direct price

-

Application:

-

Communications, automobile, consumer electronics

If desired, we will source, organise and manage all aspects of the PCB design, so that your product meets all required standards and is fully optimised for easy and cost effective manufacturing.

A well designed circuit board means:

· A reduction in production problems

· Improved quality control

· Reduced costs

· Reduced manufacturing times

We work to supply small and large batches of competitively priced printed circuit boards to our customers.

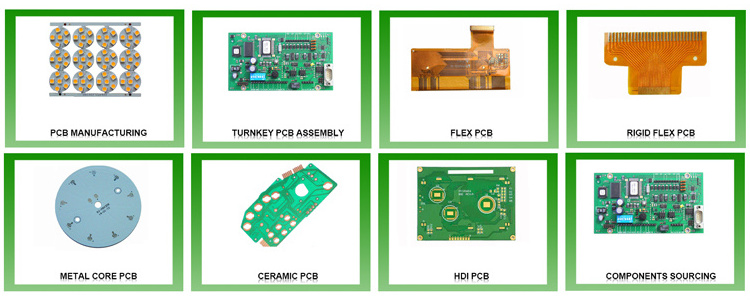

PCB&PCBA Capabilitise

PCB Capability

Number of Layer : 1 - 20 Layer

Maximum Processing Area : 680 × 1000MM

Material : FR1, 22F, CEM-1, CEM-3, FR4,

High TG, Aluminum, Ceramic, Rogers

2 Layer - 0.3MM ( 12 mil )

4 Layer - 0.4MM ( 16mil )

6 Layer - 0.8MM ( 32 mil )

8 Layer - 1.0MM ( 40 mil)

Min Board Thickness :

1

0 Layer - 1.1MM ( 44 mil )

12 Layer - 1.3MM ( 52 mil )

14 Layer - 1.5MM (59 mil )

16 Layer - 1.6MM ( 63 mil )

18Layer - 1.8MM ( 71 mil )

Thickness: ≤ 1.0MM,

Finished Board Tolerance:±0.1MM

Thickness

Tolerance : 1.0MM≤Thickness≤6.5MM

Tolerance ± 10%

Twisting and Bending : ≤ 0.75%, Min: 0.5%

Range of TG : 130 - 215 ℃

Impedance Tolerance : ±10%, Min: ± 5%

Hi-Pot TestMax : 4000V/10MA/60S

HASL, With Lead

HASL Free Lead

Flash Gold

Surface Treatment :

Immersion Gold

Immersion Silver

Immersion Tin

Gold Finger

OSP

PCB Assmbly Capability

Order Quantity : 1pc – 10,000,000+pcs

Build Time : 1 – 5 days, 1 – 2 weeks

or scheduled deliveries

PCB whose width/length is less

than 30mm should be panelized

PCB Spec Requirements :

Max board size: 500×450 mm

Board Type: Rigid PCBs, Flexible

PCBs, Metal core PCBs

Surface mount, Thro-hole

Mixed technology (SMT & Thru-hole)

Assembly Types :

Single or double sided placement

Conformal coating

Shield cover assembly for

EMI

emission

control

Solder Type : Lead-free – RoHS

Full Turnkey

Parts Procurement :

Partial Turnkey

Kitted/Consigned

SMT 01005 or larger

BGA 0.4mm pitch, POP (Package on

Component types : Package), WLCSP 0.35mm pitch

Hard metric connectors,

C

able&wire

SMT Parts

Presentation :

Bulk, Cut tape, Partial reel, Reel

Tube, Tray

Stencils : Laser-cut stainless steel

Free DFM Review, Box Build Assembly

Other Techniques :

100% AOI test and X-ray test for BGA

IC programming, Components cost-down

Function test as custom, Protection tech

It can be a challenge to find the optimal supplier for PCBs – meeting each and all customers’ expectations and requirements on price, quality, lead times, value-added services, and delivery.

Wonderful PCBs

is confidant that we meet each and every expectations for your each PCB.

Production Flow

|

Our advantage

|

|

|

|

|

||||

|

Material Technology

|

Our Production

|

|

|

General Production

|

||||

|

Regular/Special

|

1.Our (TG170)FR4:

high quality materials, excellent heat resistance, won't distort break in high temperature, no foaming, no burning, good performance in electrical charge, impact resistance, humidity-resistance 2.Our FR4 good performance in electrical charge, impact resistance, humidity-resistance 3.Our CEM no-burr 4.Our Rogers Good performance in high frequency 5.Our Aluminum Excellent heat dispersion |

|

|

1.General FR4

High heat work 2.General CEM Expand and deform in damp conditions |

||||

|

Factory

|

We have automatic production line. The automatic production line improves the precision and efficiency of PCB producing,it makes

surface brighter, cleaner and more smooth, and it helps reduce the cost. |

|

|

Artificial production line

|

||||

|

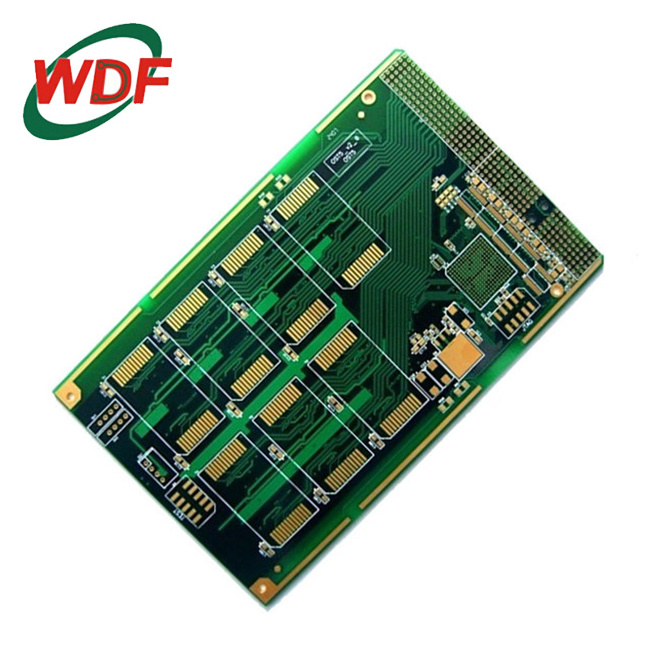

Blind/buried via board, High Density Interconnect(1+1,N+1)

|

Application of HDI technology reducing the thickness and the volume of PCB boards, increasing the density of 3-D wiring design.

|

|

|

Difficult manufacturer, high cost

|

||||

|

Impedance

|

Good performance in reliability and stability of signal sending and receiving

|

|

|

High cost

|

||||

|

Surface Technics

|

1.IMG:smooth surface, good adhesion, no oxidation under long using

2.gold plating(thick gold:1-50U"):good wear-resistance 3.HASL:better price, not easy oxidation, easy to welding, smooth surface 4.HAL: better price, not easy oxidation, easy to welding |

|

|

1.IMG:high price

2.Gold plating(thick gold):high price 3.HAL:surface is not flat, not suitable for BAG packaging |

||||

|

Copper Via/Surface(20-25UM,0.5-60Z)

|

Laser holing: Min 0.1MM, Mechanical holing: Min 0.2MM

|

|

|

Hard to reach 0.1MM

|

||||

|

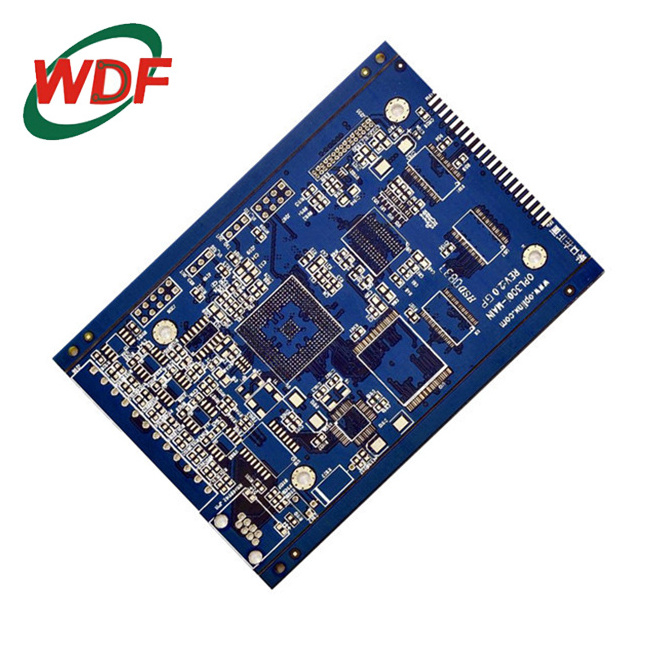

Multilayer board(4-20 L),BGA(CPU)

|

BGA:high density, high performance, multifunctional, increase thermal reliability, good performance in electroheat property, MIN

width/space: 3/3MIL Multilayer board:strong microporous, high reliability |

|

|

Difficult manufacturer,high cost

|

||||

|

Test

|

To assure quality, avoid wasting after installing and scraping, save cost, save the time of rework

|

|

|

Careless

|

||||

About Us

Contact Us

Hot Searches