- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Swiss

-

Brand Name:

-

YUBAO

-

Product Name:

-

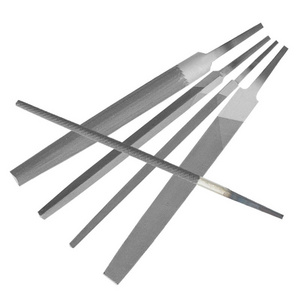

Swiss steel file

-

File Cut Type:

-

Double-cut

-

Teeth Type:

-

Medium-toothed

-

custom LOGO:

-

Yes

-

Material:

-

Special steel, forged and ground processed

-

Length Specifications:

-

140/180/200mm

-

File Shape:

-

Round/Square/Flat/triangle/Half Round/Willow Leaf

-

Application:

-

Polishing

Quick Details

-

Style:

-

Swiss Pattern File

-

Shape:

-

Round, Square, Flat, triangle, Taper, Half Round

-

Type:

-

Saw Files, Mini Files

-

Place of Origin:

-

Swiss

-

Brand Name:

-

YUBAO

-

Product Name:

-

Swiss steel file

-

File Cut Type:

-

Double-cut

-

Teeth Type:

-

Medium-toothed

-

custom LOGO:

-

Yes

-

Material:

-

Special steel, forged and ground processed

-

Length Specifications:

-

140/180/200mm

-

File Shape:

-

Round/Square/Flat/triangle/Half Round/Willow Leaf

-

Application:

-

Polishing

Products Description

|

Name

|

Swiss double head wax file

|

|

Tooth pattern

|

Geometric tooth pattern (1/2/3/4 represents the delicateness of tooth pattern, the larger the number, the delicate the tooth

pattern) |

|

Material

|

Special steel, forged and ground processed

|

|

Length Specifications

|

140/180/200mm

|

|

File Shape

|

Round/Square/Flat/triangle/Half Round/Willow Leaf

|

|

Notes

|

1.When rough processing, apply chalk gray on the fine file to reduce the space for confetti, which can keep the file sharp and avoid excessive confetti in the confetti groove and scratch the surface of the workpiece.

2.When finishing, use a file to be more particular, and you need to choose fine files and oily files.According to the processing balance, do not use blind force, slowly push back.As long as you strictly follow the correct operation method, you can completely process workpieces that meet.

|

|

Material

|

High Carbon Steel

|

|

Features

|

1. The cut teeth are uniform and the lines are clear: cutting and grinding is easier and labor-saving, greatly improving work

efficiency; 2. Wide range of applications: The file is made of high-quality molten steel, which has a longer service life and is finely processed by a lathe to make the file more uniform. It is a tool for grinding watches, jewelry, hardware, carving wax, etc. |

|

customization

|

support

|

|

sample

|

support

|

Our company

Welcome to Yubao!

Shenzhen Yubao Jewelry Equipment Co., Ltd. Our company was established in 1993.The company has a full set of jewelry production process equipment,currently.We have our own r&d team, technical team, sales team, and after-sales team with approximately 200 employees.Design molding baking mold casting polishing cleaning jewelry detection laser engraving welding customer logo marking oem packaging, etc. . It is also equipped with various forming tools,carvings, inlay, welding, polishing, car flowers, electroplating, testing, wax injection, mold release and other tools.

Certifications

Our factory

Our exhibition

Packing & Delivery

FAQ

Q1: Who are we?

A: We are manufacturers.Our headquarters is located in Guangdong, China. Since 1993, our company has been established for 30 years and has established multiple branches. And collaborate with multiple brand companies.

Q2: Can I get the sample?

A: Yes, we can provide free samples for some small products. You only need to pay the courier fee.

Q3: Regarding packaging and transportation.

A: Bulk or pallet packaging. Express delivery, sea or air freight.

Q4: How to install the product?

A: We have video instructions on the installation steps for products in the store. You can also ask our customer service personnel.

Q5: How to order our products?

A: Firstly, let us understand your needs or applications.

Secondly, we will provide a quotation based on your requirements or our suggestions.

Thirdly, the customer confirms the sample and pays a deposit for the official order.

Fourth: We arrange production.

Q6: Do you test all products before shipment?

A: Yes, we have 100% testing before delivery.

Q7: Do you have product technical support?

A: We have certifications such as ISO9001 and CE, and attach great importance to our product production process. We also have 10 QC researchers and engineers, with over 30 years of industry experience.

Hot Searches