- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1500*1500 mm

-

Voltage:

-

380V (CUSTOMIZED)

-

Power:

-

customized

-

Weight (KG):

-

4200

-

Keywords:

-

sawdust charcoal carbonization furnace

-

Carbonization time:

-

6-10 h

-

Capacity:

-

3 batches/day

-

Raw material:

-

Coconut Shell,sawdust,rick husk,wood,etc.

-

Heating source:

-

Firewood Coal Gas Electricity Burner

-

Final product usage:

-

Make Shisha Bbq Charcoal Briquettes

-

Carboniztion type:

-

Batch carbonization

-

Main structure:

-

hosting system with frame

-

Machine Size:

-

diameter:1.5*1.5 m

-

Feature:

-

Wood Charcoal Carbonization Stove Smokeless

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

flysun

-

Effective Volume:

-

2.64 m3

-

Dimension(L*W*H):

-

1500*1500 mm

-

Voltage:

-

380V (CUSTOMIZED)

-

Power:

-

customized

-

Weight (KG):

-

4200

-

Keywords:

-

sawdust charcoal carbonization furnace

-

Carbonization time:

-

6-10 h

-

Capacity:

-

3 batches/day

-

Raw material:

-

Coconut Shell,sawdust,rick husk,wood,etc.

-

Heating source:

-

Firewood Coal Gas Electricity Burner

-

Final product usage:

-

Make Shisha Bbq Charcoal Briquettes

-

Carboniztion type:

-

Batch carbonization

-

Main structure:

-

hosting system with frame

-

Machine Size:

-

diameter:1.5*1.5 m

-

Feature:

-

Wood Charcoal Carbonization Stove Smokeless

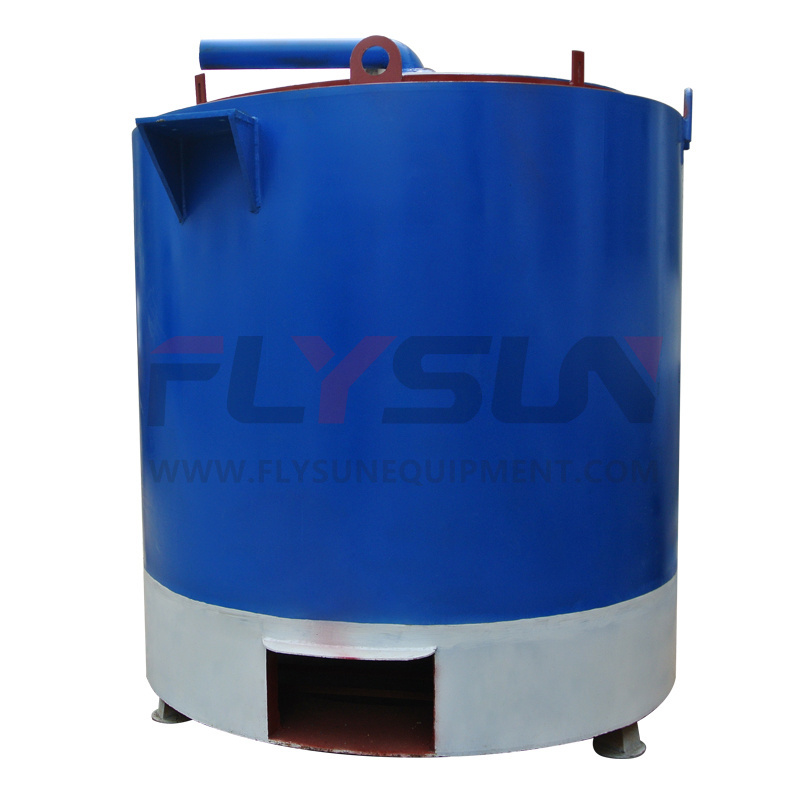

Sawdust Charcoal Carbonization Furnace Oxygen-free Carbonization Stove Charcoal Making Machine For Shisha

The Details of Sawdust Charcoal Carbonization Furnace Oxygen-free Carbonization Stove Charcoal Making Machine For Shisha:

Charcoal carbonizing furnace is a kind of equipment used to convert wood into charcoal. Its principle is to heat wood through high temperature, so that it decomposing in an oxygen-deficient environment, thus producing charcoal. Carbonizing furnace is usually composed of a furnace body and a combustion chamber. The combustion chamber is used to burn wood to produce high temperature flue gas, which is heated and decomposed through the wood in the furnace body. In this process, the water and volatile organic compounds in the wood are released, and the cellulose and hemicellulose of the wood are converted into charcoal.

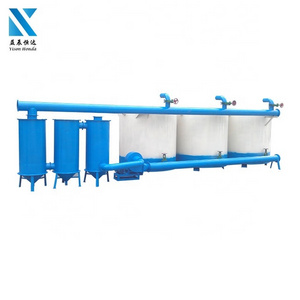

The carbonization furnace can be divided into hoisting carbonization furnace (Hositing system to cabronize bigger size materials), horizontal carbonization furnace (Without using electricity and suitable for big size materials), continuous carbonization furnace (can be fully automatic and continuous production, suitable for large-scale production required, it is used for carbonizing small-sized materials, such as shredded coconut shells, rice husks, wood chips, etc.)

Details of Sawdust Charcoal Carbonization Furnace Oxygen-free Carbonization Stove Charcoal Making Machine For Shisha:

Widely applicable to a variety of raw materials:

The main parameters of sawdust charcoal carbonization furnace:

| Model | FSC-1 | FSC-2 | FSC-3 | FSC-4 |

| Out stove size | φ2200mm Height:2300mm | φ2200mm Height:2300mm | φ2200mm Height:2300mm | φ2200mm Height:2300mm |

| Out stove qty. | 1 | 2 | 3 | 4 |

| Inner stove qty. |

φ1500/1480/1460mm Height:1500mm |

φ1500/1480/1460mm Height:1500mm |

φ1500/1480/1460mm Height:1500mm |

φ1500/1480/1460mm Height:1500mm |

| Hosting system with frame | 3 | 6 | 9 | 12 |

| Machine weight(kg) | 4200 | 9000 | 13600 | 17800 |

| Purification system | 1 | 2 | 3 | 4 |

| Caps with temperature decector | 3 | 6 | 9 | 12 |

| Capacity(m3) |

2.64 m ³ /batch 3 batches/day |

5.28m ³ /batch 3 batches/day |

7.92m ³ /batch 3 batches/day |

10.56m ³ /batch 3 batches/day |

| Cooling time | 12 | 12 | 12 | 12 |