- Product Details

- {{item.text}}

Quick Details

-

Thermal Conductivity:

-

0.055-0.180

-

Thickness:

-

6/10/15/20/25/30/40/50 mm

-

Width:

-

610-1220mm

-

Length:

-

600-1220mm(600/900/1000/1200)

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

3 (24hours)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

HP 1260 Board

-

Brand Name:

-

ROSEWOOL

-

Color:

-

White

-

AL2O3+SiO2:

-

97% min

-

AL2O3:

-

47%min

-

Na2O+K2O content:

-

0.2%

-

Organic content(%):

-

≤8%

-

Water content(%):

-

≤1%

-

Raw material:

-

Spuned Ceramic Fiber Bulk

-

Quality control:

-

ISO quality managerment

-

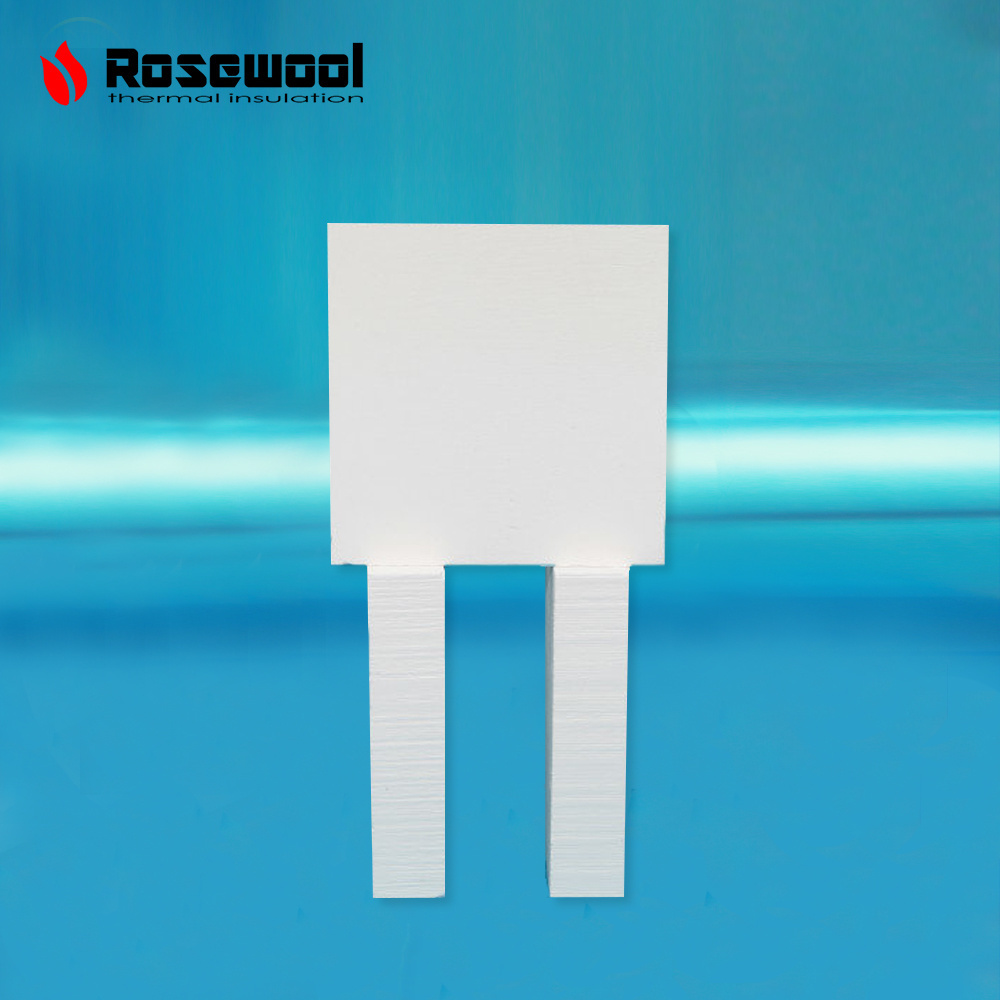

Product name:

-

ceramic fiber Insulation board

-

Density:

-

280-600kg/m3

Quick Details

-

Chemical Composition:

-

AL2O3+SIO2+ZrO2

-

Ultimate Strength (≥ MPa):

-

0.5MPa

-

Fiber Diameter:

-

3-5um

-

Thermal Conductivity:

-

0.055-0.180

-

Thickness:

-

6/10/15/20/25/30/40/50 mm

-

Width:

-

610-1220mm

-

Length:

-

600-1220mm(600/900/1000/1200)

-

Working Temperature:

-

1100C/1260C/1360C/1430C

-

Shrinkage (1800℉, 3h):

-

3 (24hours)

-

Place of Origin:

-

Henan, China

-

Model Number:

-

HP 1260 Board

-

Brand Name:

-

ROSEWOOL

-

Color:

-

White

-

AL2O3+SiO2:

-

97% min

-

AL2O3:

-

47%min

-

Na2O+K2O content:

-

0.2%

-

Organic content(%):

-

≤8%

-

Water content(%):

-

≤1%

-

Raw material:

-

Spuned Ceramic Fiber Bulk

-

Quality control:

-

ISO quality managerment

-

Product name:

-

ceramic fiber Insulation board

-

Density:

-

280-600kg/m3

1260C 300kg/m3 ceramic fiber rigid Insulation board for wood stove

ROSEWOOL ceramic fiber board are refractory and insulation material, take ceramic fiber as the main raw materials, after fiber processing, slag removing, then add some binder, through vacuum forming process and drying process, to be made into high strength fiber board.

|

Chemical Content |

Common Grade |

Standard Grade |

High pure Grade |

High alumina Grade |

Zirconium Grade |

|

AL2O3 |

44% |

46% |

47-49% |

52-55% |

39-40% |

|

AL2O3+SiO2 |

96% |

97% |

99% |

99% |

82-84% |

|

ZrO2 |

- |

- |

- |

- |

15-17% |

|

AL2O3+SiO2+ZrO2 |

- |

- |

- |

- |

99% |

|

Fe2O3 |

≤1.2% |

≤1.0% |

≤0.2% |

≤0.2% |

≤0.2% |

|

Na2O+K2O |

≤0.5% |

≤0.5% |

≤0.2% |

≤0.2% |

≤0.2% |

1. Excellent thermal stability.

2. Excellent chemistry quality.

3. Resistance to burning.

4. Low thermal conductivity

♦ The wall liner and back lining materials of high-temperature reaction, reheating equipment and various industrial furnace .

♦ Insulating and fire proof plate of furnace door and roof or house chimney and fireplace.

♦ Lows fire proof and insulation for chimney cake ovens, pizza oven.

♦ boilers and heater combustion chamber

We are Zhengzhou ROSEWOOL Insulation Refractory Co., Ltd specializing in the researching, developing and manufacturing, has more than 60 years of production experience.

1. 1 national R&D institution : Peking University has close relations of cooperation laboratory in product development and technology with us

2. 4 kinds : Our product range: ceramic fiber products (blanket, paper, board, module,also special shape), rock wool , glass wool , calcium silicate board.

3. 5 certificate : ISO900, CE, SGS, TUV, BV, etc.

4. 23 years : Our export experience more than 23 years.

5.

150,000 m2

: Our factory total areas.

Our value is: To the quality strives for the survival,

Energy saving cause parallel

If you have any question,please contact Rosewool any time.