- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Boyou

-

Voltage:

-

220V/380V

-

Power (kW):

-

3 kW

-

Marketing Type:

-

Other

-

Function:

-

mixer homogenizer emulsifer

-

Homogenizer:

-

bottom homogenizer

-

Homogenizer Speed:

-

0-3000 RPM

-

Top Mixer:

-

0-60 RPM

-

Stirrer Type:

-

wall scraper mixer

-

Heating Method:

-

Electric Steam Heating

-

Volume:

-

100L~10000L

-

Delivery Time:

-

30 days

-

Product name:

-

Automatic Vacuum Homogenizing Emulsifier/cake Gel Emulsifier Making Ma

Quick Details

-

Barrel Volume (L):

-

100L

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

1 - 60 r.p.m

-

Weight (KG):

-

300 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Boyou

-

Voltage:

-

220V/380V

-

Power (kW):

-

3 kW

-

Marketing Type:

-

Other

-

Function:

-

mixer homogenizer emulsifer

-

Homogenizer:

-

bottom homogenizer

-

Homogenizer Speed:

-

0-3000 RPM

-

Top Mixer:

-

0-60 RPM

-

Stirrer Type:

-

wall scraper mixer

-

Heating Method:

-

Electric Steam Heating

-

Volume:

-

100L~10000L

-

Delivery Time:

-

30 days

-

Product name:

-

Automatic Vacuum Homogenizing Emulsifier/cake Gel Emulsifier Making Ma

Products Description

stainless steel mixing tank vacuum emulsifier homogenizer mixer for cream tomato paste ointment emulsifying machine

Vacuum Emulsifier Homogenizer Mixer is making production under the vacuum condition, it makes use of the high

shear emulsifier to distribute one or several phases to another continuous phase rapidly and evenly. The materials will be

processed in the narrow space between stator and rotor by strong energy of motion produced by the mechanical effect. By the operation of hydraulic shearing, centrifugal extruding, impacting, breaking and turbulence for over 100 thousand times per minute, the materials will be dispersed and emulsified instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

shear emulsifier to distribute one or several phases to another continuous phase rapidly and evenly. The materials will be

processed in the narrow space between stator and rotor by strong energy of motion produced by the mechanical effect. By the operation of hydraulic shearing, centrifugal extruding, impacting, breaking and turbulence for over 100 thousand times per minute, the materials will be dispersed and emulsified instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

Features:

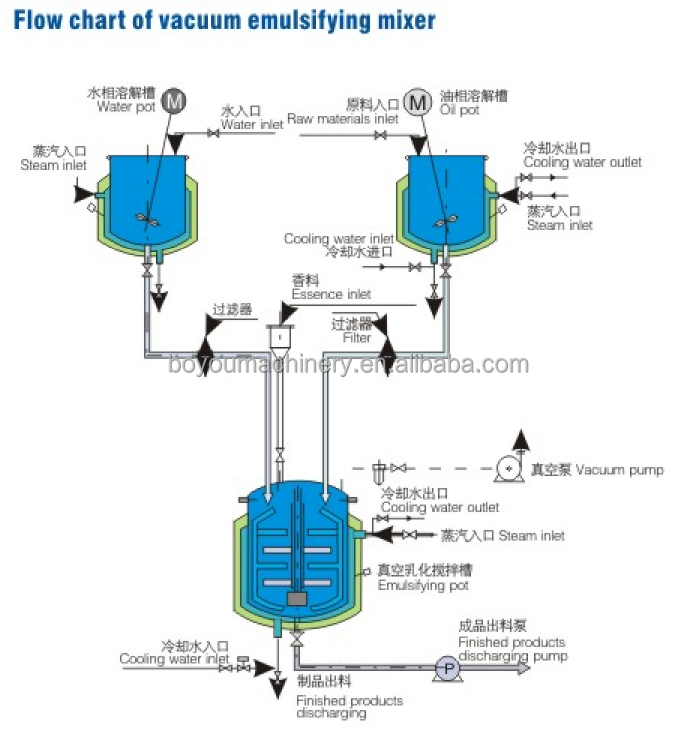

1. Vacuum Emulsifier Homogenizer Mixer is consists of 3 tanks, main tank and 2 preheating tanks;

2. with vacuum function;

3. with hydraulic lifting up and down systems;

4. electric heating or steam heating optional;

stainless steel mixing tank vacuum emulsifier homogenizer mixer for cream tomato paste ointment emulsifying machine

suitable for production of cream, tomato paste, ointment, lotions, paintings, adhesives etc.

Vacuum Suction Function to suck raw materials from the oil/water preheating tanks

1. Hydraulic lifting system for tank lid up and down;

2. Tank tilting function controlled by handwheel or motor;

1. Top wall scraper mixer with teflon scraper to prevent any materials from sticking to the pot;

2. Wall-scraper mixer speed 0-60RPM adjustable;

1. Bottom high shear homogenizer 0-3000 RPM adjustable;

2. temperature probe to monitor products temperature;

1. Water Preheating Tank;

2. Oil Preheating Tank;

to preheat raw materials to improve production efficiency;

1. Water/oil preheating tanks with bottom disperser mixing 1440RPM;

2. with heating function (electric or steam heating optional);

Product Paramenters

|

Model

|

Capacity

|

Top Mixer Power/Speed

|

Bottom Homogenizer Power/Speed

|

Heating Method

|

||||

|

VMB-10L

|

10 Liter

|

0.75KW / 0-60 RPM

|

1.5KW / 0-3000 RPM

|

Electric or Steam heating

|

||||

|

VMB-20L

|

20 Liter

|

0.75KW / 0-60 RPM

|

2.2KW / 0-3000 RPM

|

|

||||

|

VMB-50L

|

50 Liter

|

1.5KW / 0-60 RPM

|

3KW / 0-3000 RPM

|

|

||||

|

VMB-100L

|

100 Liter

|

2.2KW / 0-60 RPM

|

3KW / 0-3000 RPM

|

|

||||

|

VMB-200L

|

200 Liter

|

3KW / 0-60 RPM

|

5.5KW / 0-3000 RPM

|

|

||||

|

VMB-300L

|

300 Liter

|

4KW / 0-60 RPM

|

7.5KW / 0-3000 RPM

|

|

||||

|

VMB-500L

|

500 Liter

|

5.5KW / 0-60 RPM

|

11KW / 0-3000 RPM

|

|

||||

|

VMB-1000L

|

1000 Liter

|

11KW / 0-60 RPM

|

18KW / 0-3000 RPM

|

|

||||

|

VMB-2000L

|

2000 Liter

|

15KW / 0-60 RPM

|

22KW / 0-3000 RPM

|

|

||||

|

The above paramaters are for reference ONLY, customized machines are acceptable.

|

|

|

|

|

||||

Product packaging

Hot Searches