- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 650 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

ADH

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220

-

Dimension(L*W*H):

-

3750*1650*1800

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

Shearing plate material available:

-

20-600MM

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1.5

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 650 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

ADH

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220

-

Dimension(L*W*H):

-

3750*1650*1800

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

Shearing plate material available:

-

20-600MM

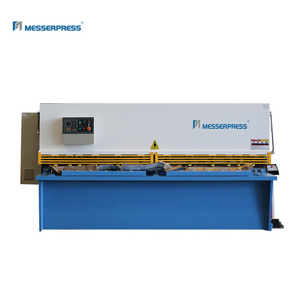

PRODUCT DESCRIPTION

SWING BEAM TYPE

·Steel plate welded structure

·Hydraulic transmission

·Nitrogen cylinder return

·Easy operation

·Reliable performance

·Beautiful appearance

·Light alignment device

·Overload protection

·Rolling material support ball

·Adopt safety protection fence

·Straightness: +0.10mm

·50% faster than others

·Blade material 6CrW2Si/H13

·Heat treatment:55-60HB

·Low noise(70bd)

·E21S,E200PS,DAC310S CNC system

FRONT VIEW

The frame and the tool holder adopt the overall welded structure,which is relieved by annealing,has high mechanical strength,good

rigidity and good precision retention.

rigidity and good precision retention.

BACK VIEW

The tool holder body adopts a three-point support rolling guide rail,and the three fulcrums are all in the form of rollers,which minimizes the friction force and ensures the gapless rolling during the movement of the tool holder.

BALL INTEGRATED FRONT TABLES

Rolling steel balls will be helpful to reduce surface scratches on the sheet.

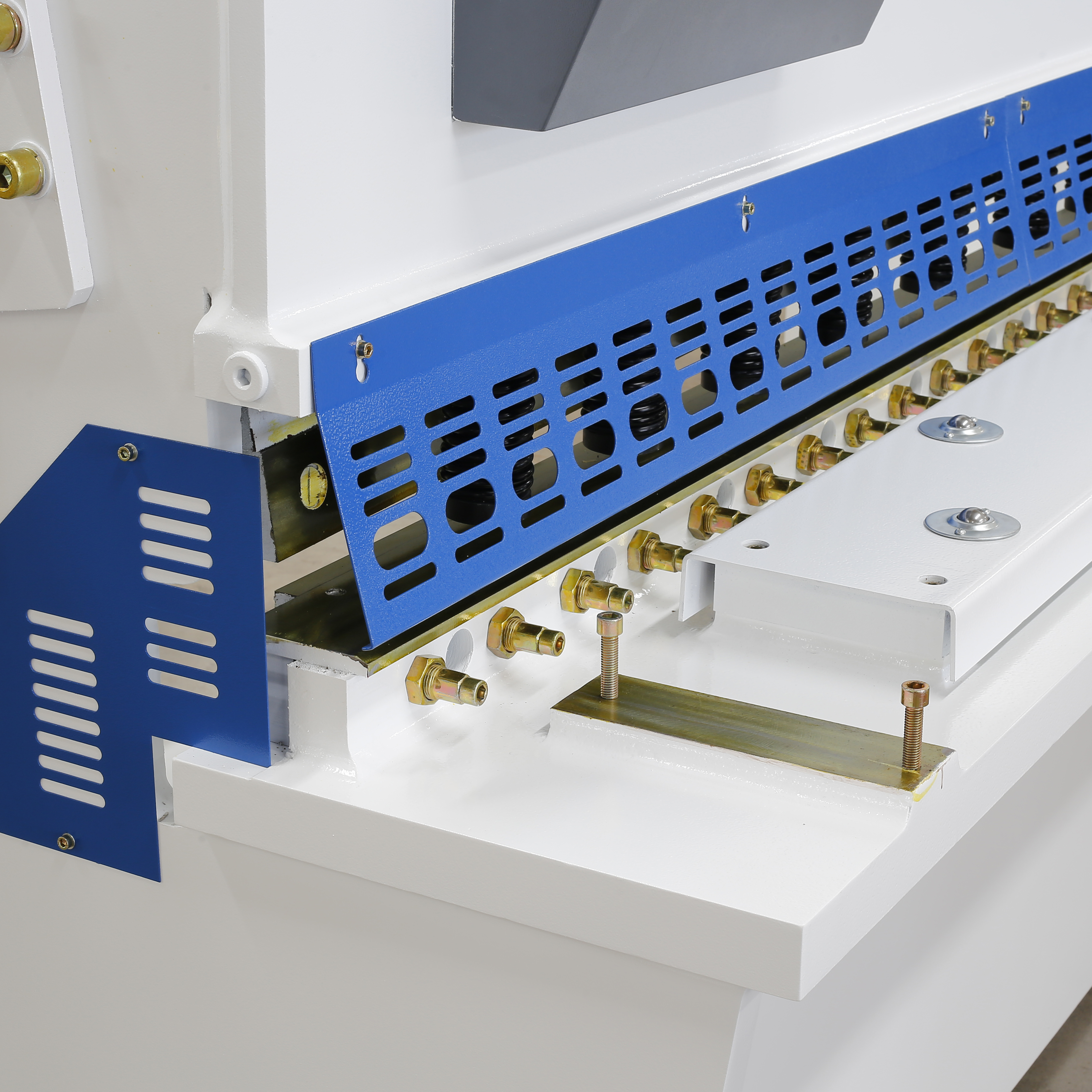

PRODUCT DETAILS

HYDRAULIC HOLD-DOWN PADS

·The lower end of the press cylinder is made of non-metal material,which has certain elasticity and large friction

coefficient.

·When cutting the sheet,the press pad can be in close contact with the material plate to provide sufficient

friction to effectively prevent the plate from being shaken during the shearing process.

coefficient.

·When cutting the sheet,the press pad can be in close contact with the material plate to provide sufficient

friction to effectively prevent the plate from being shaken during the shearing process.

BALL SCREW

·Taiwan HIWIN ball screw is adopted to ensure the movement of the backgauge in high precision.

SIEMENS MOTOR

·We're using the Siemens motor to ensure the service life of the machine.

BLADE

·Blade material 6CrW2Si.

·Only the highest quality cutting blades are used to ensure the longest service life and the least number of sharpenings.

·Only the highest quality cutting blades are used to ensure the longest service life and the least number of sharpenings.

HYDRAULIC VALVE

·The BOSCH(Rexroth) integrated hydraulic system is compact.

·The system pressure control adopts electro-hydraulic portional pressure valve,and the whole process pressure can be programmed and controlled to ensure stable and reliable machine performance.

·The system pressure control adopts electro-hydraulic portional pressure valve,and the whole process pressure can be programmed and controlled to ensure stable and reliable machine performance.

COOLING SYSTEM

·Cooling hydraulic oil.

EMERGENCY STOP

·The emergency stop button will be used if you need to stop the machine in emergent condition.

PREMIUM BACKGAUGE

·With high quality and precise backgauge which is controlled by servo motor.

ANGLE POSITIONING

·The angle positioning device has a scale rod,which is quickly processed and applied by a manual positioning lock to cut irregular sections.

· It can rotate 360.

· It can rotate 360.

REAR LIGHT CURTAIN

·For the protection of the backside.

CNC CONTROLLER

·HD LCD display, with both Chinese and English language options, a display programming parameters,faster and more convenient programming

·Backgauge control: Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device

·Cut Stroke: Built-shearing time relay, simple operation, cost savings

·Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons

·Blade gap: encoder feedback, time display blade gap size, simple operation

·Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

·All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

·CE certified to meet the needs of overseas markets.

·Color HD LCD display, with both Chinese and English language options, a display programming parameters, faster and more convenient programming

·CAN bus technology, servo control X, Y-axis, high control accuracy, resolution up to 0.001; simple to install wiring, improve system reliability.

·Built blade clearance, cutting stroke, concessions and other control functions delay.according to the actual need to set the parameters of the gap, cut away concessions and other real-time control.

·Having machine motion control features that simplify the electrical wiring cabinet.reduce costs and improve reliability.

·With self-diagnosis and real-time alarm functions, debugging and maintenance more convenient.

·Reservation security interface for easy expansion.

·Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs

·All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life.

·CE certified to meet the needs of overseas markets.

·

Bright LCD 128 x 64 display

·Backgauge control

·Gap control

·Stroke length limitation

·

Actual and Programmed position visualization

·Stock counter

·Programmable up to 100 steps

·Panel-based housing

·Servo control unipolar /AC two-speed control

OPTIONAL

|

STANDARD

|

OPTIONAL

|

|

·Hydraulic Valve: Rexroth

·Electrics: Schneider

·Oil Pump: Sunny ·Oil Cylinder: Made in China ·Main Motor: Siemens ·Ball Screw Rod:Zeen/PMl ·Linear Guide: Zeen/Schneeberger

·Front Support: Normal Type

·Back Support: Support Plate

·Line Alignment Device: Light

·Front Fence: Sheet Metal Type

·Rear Protection: Warning Tape

·Lubrication Device: Manual/Automatic Lubrication Device

·Blade: Standard materials: 9GrSi/6Crw2Si

·Pedal Switch: Simple Emergency Stop Type

·Controller: E21S

|

·Main Motor: WNM

·Ball Screw Rod: HIVVIN

·Linear Guide: HIWIN

·Front Support: Scale Adjustment Support/Angle Adjustment Suppcrt

·Line Alignment Device: Laser Marking Device/Line Alignment

·Front Fence: Light Curtain Protection/Section Upturned

·Rear Protection: Light Curtain Protection/Rear Fence

·Pneumatic Support: Pneumatic Rear Support

·Hydraulic Oil Cooling Device: Air Cooling Device

·Blade: H13

·Pedal Switch: Roller Pedal Switch |

TECHNICAL SPECIFICATION

|

Model

|

Cutting Thickness

|

Width

|

Oil Tank

|

Strokes

|

Backgauge range

|

Cutting Angle

|

Main Power

|

Weight

|

Overall Dimensions

|

|

unit

|

mm

|

mm

|

L

|

times/min

|

mm

|

°

|

KW

|

Ton

|

L×W×H mm

|

|

4*2500

|

4

|

2500

|

140

|

33

|

20-650

|

1.5

|

7.5

|

3.5

|

3035*1570*1720

|

|

4*3200

|

4

|

3200

|

190

|

15

|

20-650

|

1.5

|

7.5

|

5

|

3750*1640*1850

|

|

4*4000

|

4

|

4000

|

190

|

10

|

20-800

|

1.5

|

7.5

|

7

|

4550*1970*1900

|

|

4*5000

|

4

|

5000

|

320

|

8

|

20-800

|

1.5

|

7.5

|

13

|

5700*1900*2000

|

|

4*6000

|

4

|

6000

|

440

|

8

|

20-800

|

1.5

|

15

|

16.5

|

6500*2460*2250

|

|

6*2500

|

6

|

2500

|

190

|

15

|

20-650

|

2

|

7.5

|

5

|

3050*1650*1800

|

|

6*3200

|

6

|

3200

|

190

|

12

|

20-650

|

1.5

|

7.5

|

6

|

3750*1650*1800

|

|

6*4000

|

6

|

4000

|

190

|

9

|

20-800

|

1.5

|

7.5

|

8.2

|

4550*2000*1950

|

|

6*5000

|

6

|

5000

|

320

|

7

|

20-800

|

1.5

|

15

|

15

|

5540*2450*2300

|

|

6*6000

|

6

|

6000

|

440

|

5

|

20-800

|

1.5

|

15

|

19

|

6545*2470*2500

|

|

8*2500

|

8

|

2500

|

190

|

14

|

20-650

|

2

|

11

|

5.5

|

3060*1650*1800

|

|

8*3200

|

8

|

3200

|

190

|

10

|

20-650

|

1.5

|

11

|

6.5

|

3760*1650*1800

|

|

8*4000

|

8

|

4000

|

190

|

9

|

20-800

|

1.5

|

15

|

8.5

|

4560*1960*1920

|

|

8*5000

|

8

|

5000

|

320

|

8

|

20-800

|

1.5

|

18.5

|

15.5

|

5600*2360*2180

|

|

8*6000

|

8

|

6000

|

440

|

6

|

20-800

|

1.5

|

18.5

|

19.5

|

6600*2450*2500

|

|

10*2500

|

10

|

2500

|

190

|

10

|

20-800

|

2

|

15

|

6.5

|

3050*1960*1920

|

|

10*3200

|

10

|

3200

|

190

|

9

|

20-800

|

1.5

|

15

|

7.5

|

3800*1960*1920

|

|

10*4000

|

10

|

4000

|

400

|

8

|

20-800

|

1.5

|

22

|

10.5

|

4700*2100*2200

|

|

10*6000

|

10

|

6000

|

440

|

6

|

20-800

|

1.5

|

22

|

27.5

|

6600*2100*2300

|

|

12*2500

|

12

|

2500

|

400

|

12

|

20-800

|

2

|

22

|

9.5

|

3170*2150*2180

|

|

12*3200

|

12

|

3200

|

400

|

10

|

20-800

|

2

|

22

|

11

|

3800*2150*2180

|

|

12*4000

|

12

|

4000

|

400

|

8

|

20-800

|

1.75

|

22

|

13.3

|

4700*2285*2180

|

|

12*5000

|

12

|

5000

|

440

|

6

|

20-800

|

2

|

22

|

19

|

5800*2450*2400

|

|

12*6000

|

12

|

6000

|

440

|

5

|

20-800

|

2

|

22

|

31

|

6600*2600*2700

|

|

12*8000

|

12

|

8000

|

580

|

4

|

20-800

|

1.75

|

22

|

50

|

8600*3250*3200

|

|

16*2500

|

16

|

2500

|

400

|

11

|

20-800

|

2.5

|

22

|

10.5

|

3245*2290*2180

|

|

16*3200

|

16

|

3200

|

400

|

10

|

20-800

|

2

|

22

|

12

|

3870*2300*2180

|

|

16*4000

|

16

|

4000

|

600

|

8

|

20-800

|

1.75

|

22

|

17.3

|

4705*2575*2200

|

|

16*5000

|

16

|

5000

|

600

|

6

|

20-800

|

2.5

|

30

|

24

|

5900*2600*2700

|

|

16*6000

|

16

|

6000

|

600

|

5

|

20-800

|

2.5

|

30

|

32.8

|

6600*2700*2900

|

|

20*2500

|

20

|

2500

|

500

|

8

|

20-800

|

2.5

|

30

|

13.7

|

3300*2580*2300

|

|

20*3200

|

20

|

3200

|

500

|

7

|

20-800

|

2.5

|

30

|

15

|

4150*2600*2500

|

|

20*4000

|

20

|

4000

|

550

|

5

|

20-800

|

2.5

|

30

|

22

|

4850*2600*2800

|

|

25*2500

|

25

|

2500

|

550

|

7

|

20-800

|

3

|

37

|

16

|

3200*2700*2900

|

|

25*3200

|

25

|

3200

|

600

|

5

|

20-800

|

3

|

37

|

23

|

4200*2700*3000

|

WHO WE ARE

ADH Company, founded in 2002, is located in Ma'anshan City, Anhui Province, China. Our company covers an area of 450 Mu and mainly produces press brake machines, hydraulic shearing machines, laser cutting machines, laser automation, CNC turret punches, and sheet metal automation equipment.

ADH has three production bases, four testing centers, and three business divisions: press brake machine manufacturing, laser cutting machine manufacturing, and industrial automation manufacturing. lt is equipped with 9 heavy fioor boring machines, multiple 4-16m pentahedral gantry machining centers, a 16m large heat treatment annealing furnace, a shot blasting machine,a 20m electric welding platform, a 10000-ton bending machine special assembly platform.and some other heavy processing equipment, with an annual output of more than 5000 sets of various machine tools.

Our company has a complete set of product quality management systems, and each equipment can leave the factory only after passing the strict quality inspection process.

We have set up more than 150 offices and after-sales service outlets at home and abroad. Our service network covers the world, and our products are exported to more than 100 countries in South America, Southeast Asia, Europe, the Middle East, and other regions.

ADH, a rising brand, is committed to becoming a new driving force for the development of intelligent equipment. At the same time,we provide the best cutting and bending machine tools for customers all over the world.

Our company has a complete set of product quality management systems, and each equipment can leave the factory only after passing the strict quality inspection process.

We have set up more than 150 offices and after-sales service outlets at home and abroad. Our service network covers the world, and our products are exported to more than 100 countries in South America, Southeast Asia, Europe, the Middle East, and other regions.

ADH, a rising brand, is committed to becoming a new driving force for the development of intelligent equipment. At the same time,we provide the best cutting and bending machine tools for customers all over the world.

FABRICATION EQUIPMENT

SERVICE COMMITMENT

Our team of professional engineers carefully reviews every suggestion and provides the most suitable final solution for the user.

Our team ensures that all equipment delivered to customers meets the hiqhest quality standards

.

During the 1-3 year warranty period,we offer free replacement of parts for our customers.

We can quickly supply customized accessories to ensure our customers' machines run smoothly without interruption.

The main core components of the machine are sourced from internationally renowned brands.

We provide customized solutions that cater to the specific needs of our customers.

EXHIBITION

FAQ

Here are the most frequently asked questions by our customers.

Are you a factory or a trading company?

We are a manufacturer. Our company was founded in 2002, and has 20 years of production experience.

Where is your company?

Our company is in Maanshan, Anhui Province, which is only half an hour’s drive from Nanjing Lukou Airport. If you visit our company, we will arrange a special bus to meet you at the airport.

How long does it take to deliver the machine?

Generally, we will deliver the goods within 30 days. If the machine belongs to non-standard customized products, the time will be longer, but the longest time will not exceed 50 days.

What kind of payment do you accept?

Generally, we accept T/T and L/C payment, 30% deposit and 70% payment before delivery. If you are our special customer, we can accept better payment method.

What is the warranty period of your machine?

For conventional machines, our warranty period is one year. For special non-standard machines, we may provide a 2-3 year warranty,but this should be confirmed with our sales team in advance. During the warranty period, we provide free replacement parts.

Do you accept OEM customization?

Yes, we accept OEM customization, such as customized machine appearance, color, configuration, etc. Of course, the price of customized products should be a little higher. Please contact our business team for details.

Hot Searches