- Product Details

- {{item.text}}

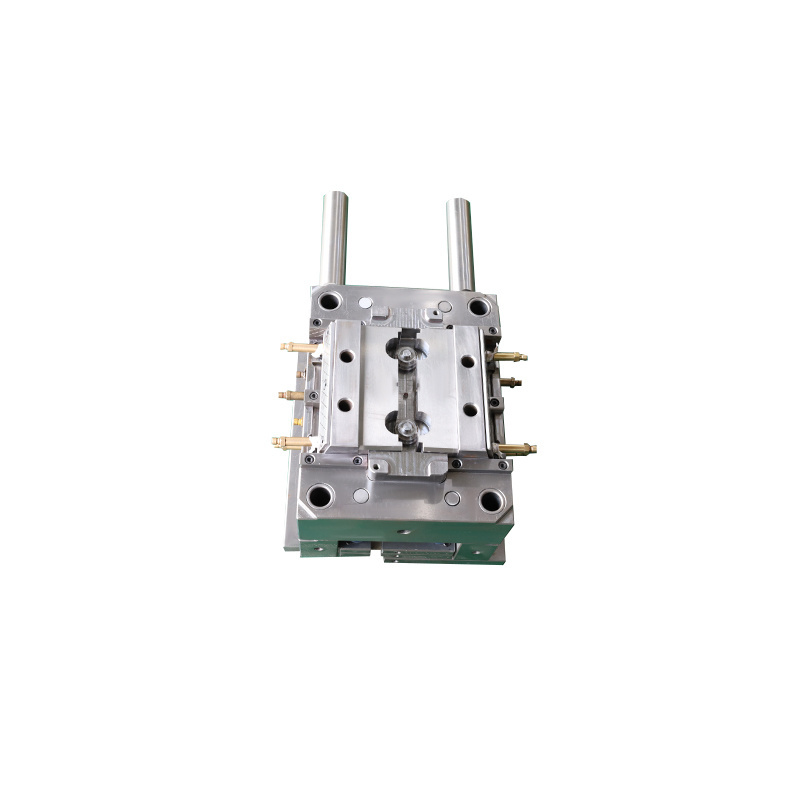

Quick Details

-

Model Number:

-

PY-S110

-

Surface treatment:

-

Polish, Etched,Texture

-

Plastic part material:

-

ABS,PP,PC,PA,NYLON,TPU

-

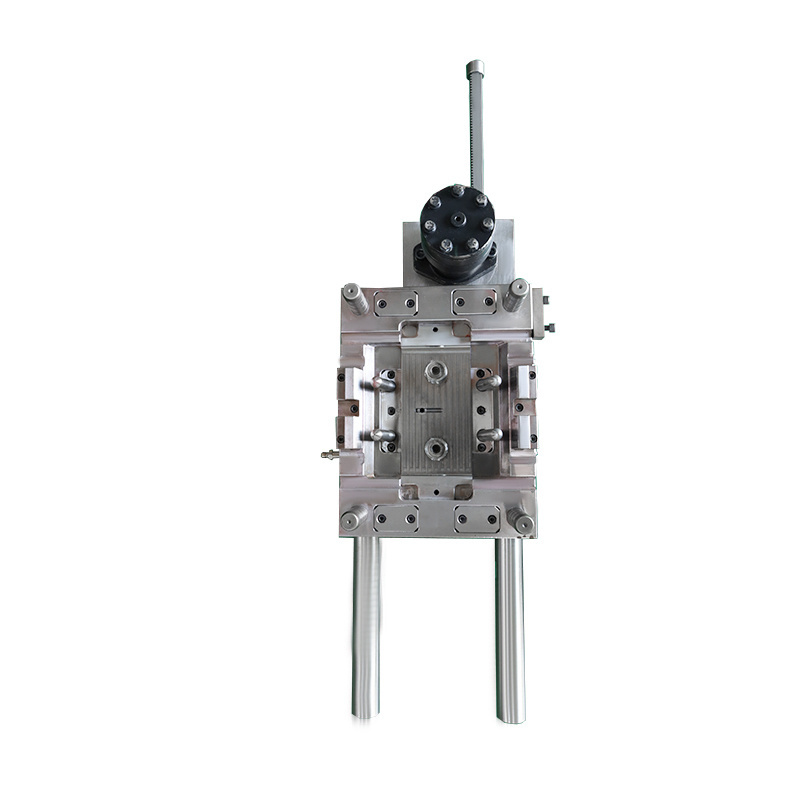

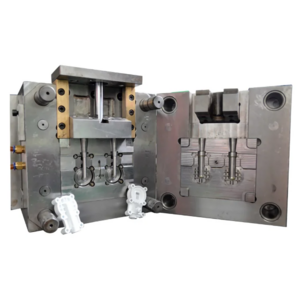

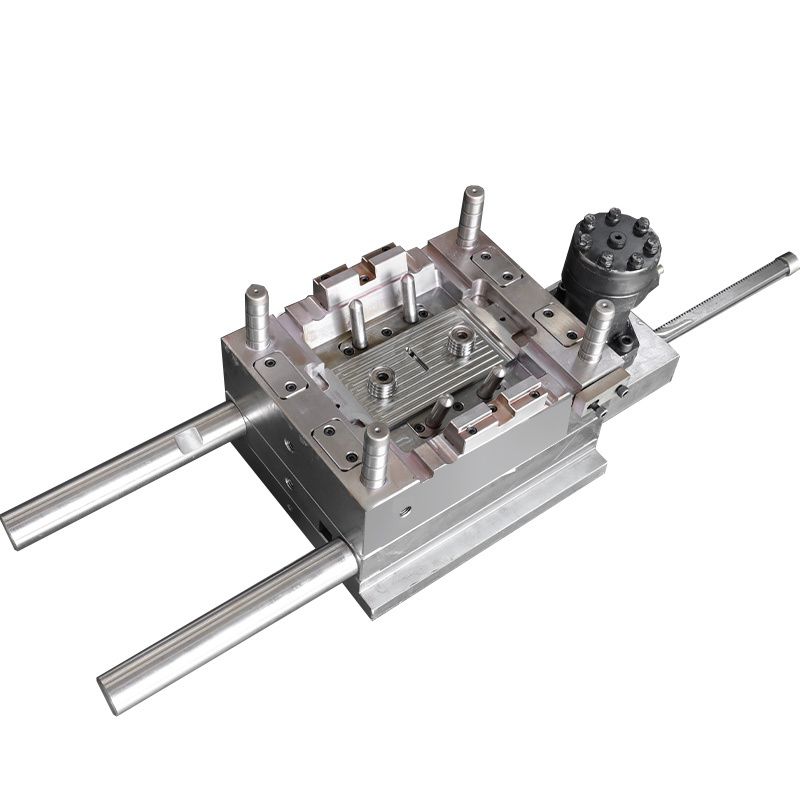

Mould material:

-

NAK80,S136,2344,718H

-

Mould base:

-

LKM,HASCO,FUTABA,DME

-

Runner:

-

Hot Runner,Cold Runner

-

Mould life:

-

300000-1000000 Shots

-

Cavity:

-

Single Cavity, Multi Cavity

-

Gate type:

-

Point gate,Edge gate,Sub gate in part,Fan gate

-

Certifications:

-

ISO 9001.2015,TS16949

-

Scope of application:

-

car, Instruments, Cell Phones, Electronics, Medical, Home Appliances

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PUYUAN

-

Model Number:

-

PY-S110

-

Surface treatment:

-

Polish, Etched,Texture

-

Plastic part material:

-

ABS,PP,PC,PA,NYLON,TPU

-

Mould material:

-

NAK80,S136,2344,718H

-

Mould base:

-

LKM,HASCO,FUTABA,DME

-

Runner:

-

Hot Runner,Cold Runner

-

Mould life:

-

300000-1000000 Shots

-

Cavity:

-

Single Cavity, Multi Cavity

-

Gate type:

-

Point gate,Edge gate,Sub gate in part,Fan gate

-

Certifications:

-

ISO 9001.2015,TS16949

-

Scope of application:

-

car, Instruments, Cell Phones, Electronics, Medical, Home Appliances

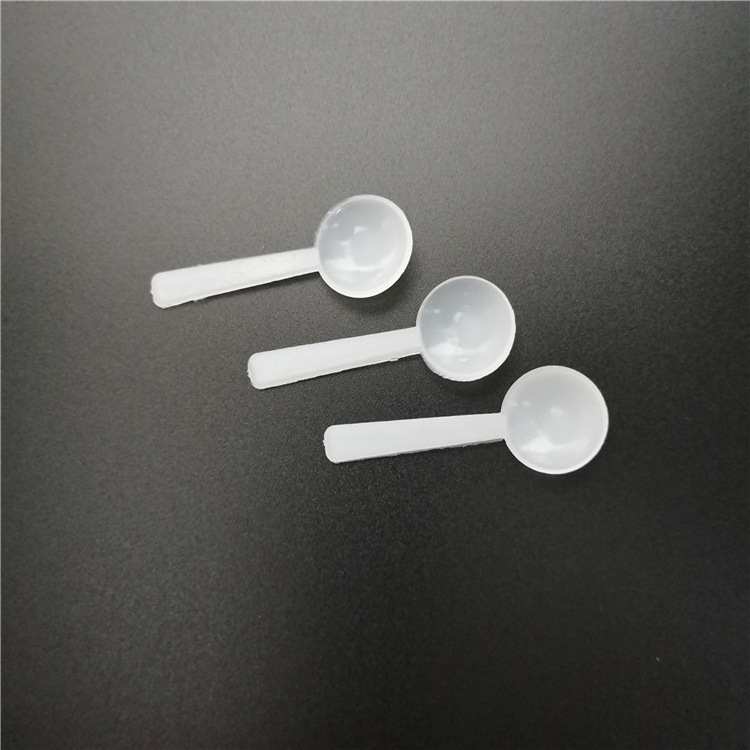

pp plastic spoon 10 gram powder scoops plastic cheap plastic injection mold makers

Product Paramenters

|

Product Name

|

molding plastic parts injection

|

|

Plastic Material

|

PP, ABS, ABS+PC, PC, TPE/TPE, PA66/PA6, PMMA, PBT, HDPE, etc..

|

|

Factory Certification

|

ISO 9001.2015,TS16949,etc...

|

|

Plastic Certification

|

RoSH, SGS, food grade, Medical grade, UL, UV

|

|

Mold building time

|

Mostly 2-5 weeks, can be flexible to meet with your urgent delivery

|

|

Surface Treatment

|

Texture, gloss, polishing, silk printing, painting, etc..

|

Products Description

Main Features of IMD/IML/IME plastic injection moulding:

1) It makes the product resistant to friction and prevents the surface from being scratched;

2) The colors of the products are far bright and no easy to fade for a long time;

3) Currently it is the most efficient method, it requires printing, high pressure forming, die cutting on the surface of the

film,then finally combined with plastic for molding, this avoids the second processing procedure and the labor time;

4) Especially in the printing process required for backlight, multi-surface, imitation metal, hairline processing, logic light

pattern, rib interference...which are unable to make, then that is the exact time to use IMD technology.

1) It makes the product resistant to friction and prevents the surface from being scratched;

2) The colors of the products are far bright and no easy to fade for a long time;

3) Currently it is the most efficient method, it requires printing, high pressure forming, die cutting on the surface of the

film,then finally combined with plastic for molding, this avoids the second processing procedure and the labor time;

4) Especially in the printing process required for backlight, multi-surface, imitation metal, hairline processing, logic light

pattern, rib interference...which are unable to make, then that is the exact time to use IMD technology.

Details Images

Our Advantages

Our Service:

1). We Export the Mould For

you Only

;

2). We Make the Mould and Do Injection Molding;

3). Provide Assembling Service as well.

4). We have rich experience in IML mold and injection molding.

2). We Make the Mould and Do Injection Molding;

3). Provide Assembling Service as well.

4). We have rich experience in IML mold and injection molding.

The Whole Mould Making Processings are done in our own factory.

(Grinding-Drilling-EDM-WEDM-CNC Machining-Polishing-Mould Testing...)

(Grinding-Drilling-EDM-WEDM-CNC Machining-Polishing-Mould Testing...)

Notes: Our factory is mainly providing Mould Making / Plastic injection molding / Assembly Service under OEM/ODM base.

Hot Searches