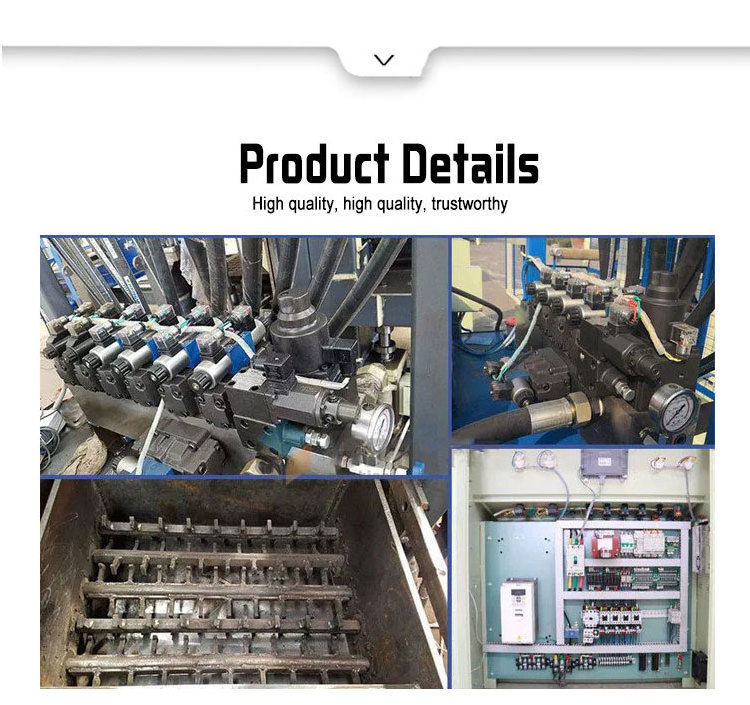

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China, SHN

-

Weight (KG):

-

1350 kg

-

Raw material:

-

Fly Ash

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product Name:

-

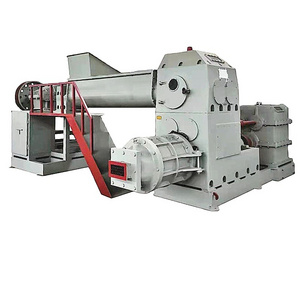

Concrete Block Machine Block Making Machine

-

Block Type:

-

Hollow Concrete Brick Machine

-

Name:

-

Cement Brick Block Making Machine

-

Brand Name:

-

Donyue

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Keywords:

-

Automatic Cement Block Moulding Machine

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

China, SHN

-

Weight (KG):

-

1350 kg

-

Raw material:

-

Fly Ash

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product Name:

-

Concrete Block Machine Block Making Machine

-

Block Type:

-

Hollow Concrete Brick Machine

-

Name:

-

Cement Brick Block Making Machine

-

Brand Name:

-

Donyue

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Keywords:

-

Automatic Cement Block Moulding Machine

Division I mainly produces cement brick machine, hollow brick machine, brick making

machine, etc., and supplies automatic baking-free brick machine.

machine, etc., and supplies automatic baking-free brick machine.

Advantage

1. Using reliable electric control technology, the operation is simple and the operation is reliable.

2. The machine body adopts special double-end synthetic output vibration technology to optimize the arrangement of vibrators, so that the exciting force is evenly distributed in the shaking table.

3. By adopting the form of compaction vibration, the concrete can be fully liquefied and exhausted within 2-3S to ensure the high density of products. It is especially suitable for producing high-strength standard bricks, which can be palletized after molding, saving a lot of pallet investment.

4. The vibration technology and arch-breaking device are used together to realize the integrated vibration control of cloth, so as to achieve the homogenization of cloth and optimization of forming.

5. The machine has strong applicability, can be used for multiple purposes, can be installed with different molds, and can produce wall blocks, standard bricks, hollow bricks, porous bricks and the like with various specifications.

2. The machine body adopts special double-end synthetic output vibration technology to optimize the arrangement of vibrators, so that the exciting force is evenly distributed in the shaking table.

3. By adopting the form of compaction vibration, the concrete can be fully liquefied and exhausted within 2-3S to ensure the high density of products. It is especially suitable for producing high-strength standard bricks, which can be palletized after molding, saving a lot of pallet investment.

4. The vibration technology and arch-breaking device are used together to realize the integrated vibration control of cloth, so as to achieve the homogenization of cloth and optimization of forming.

5. The machine has strong applicability, can be used for multiple purposes, can be installed with different molds, and can produce wall blocks, standard bricks, hollow bricks, porous bricks and the like with various specifications.

FULLY AUTOMATIC SYSTEM

Full automatic cement brick making machine adopts four bar guiding mode to ensure the accurate movement of

the indenter and mold.

the indenter and mold.

HOPPER

The new semi closed hopper is equipped with linear reciprocating plate, which can quickly and evenly add materials to the

mould of brick machine.

mould of brick machine.

PLC INTELLIGENTCONTROLI

S

Using imported color touch screen and programmable controller PLC control equipped with data input and output device control system including safety logic control and fault diagnosis system.

SIEMENS MOTOR

Thickened pure copper wire, silent device, achieve high operation, improve service life, safe and reliable.

ONE MACHINE FORMULTIPLE PURPOSES

Through changing the mould of brick machine, it can produce different specifications of porous brick, hollow block, inspection well, pavement brick and other cement products.

|

Overall dimensions of forming machine

|

1850*1880*224

|

|

|

|

|||

|

molding cycle

|

20-24s

|

|

|

|

|||

|

Vibration force

|

33.5

|

|

|

|

|||

|

Host power

|

13.45kw

|

|

|

|

|||

|

Main engine weight

|

6T

|

|

|

|

|||

|

Pallet size

|

850*550*20

|

|

|

|

|||

Hot Searches