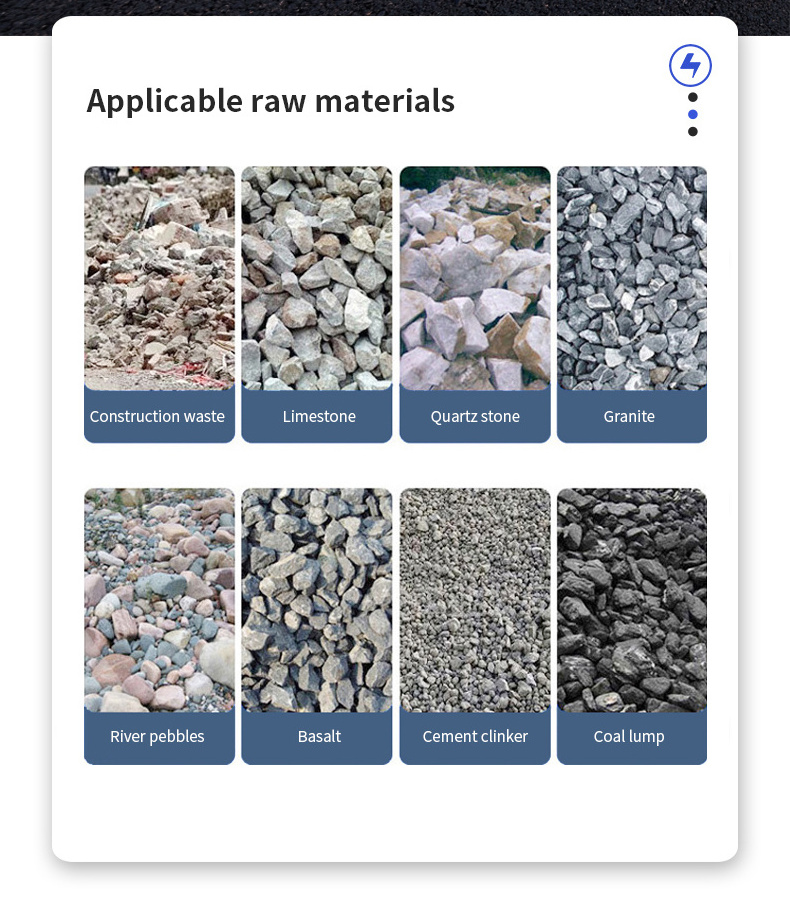

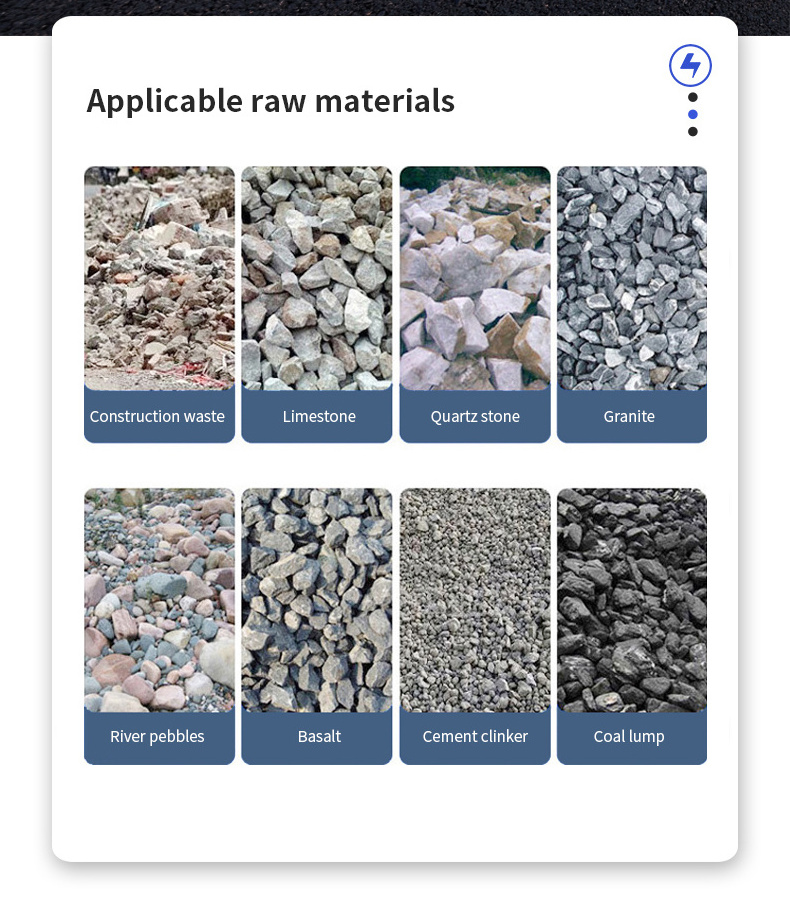

Granite, Basalt, Quartz, Gold Ore, Copper Ore, Iron Ore, River Pebbles, Marble.etc

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

130*100*100cm

-

Weight:

-

1200 KG

-

Product name:

-

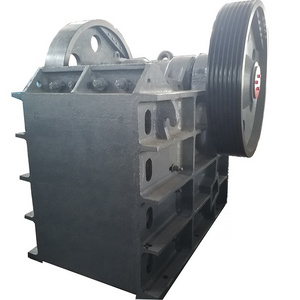

Jaw Crusher Machine

-

Raw material:

-

Stones Rocks Ores

-

Function:

-

Mining Crusher Equipment

-

Inlet port size:

-

200*300mm

-

input size:

-

180mm

-

output size:

-

15-50mm

-

Production Capacity:

-

2-6t/h

-

Eccentric shaft speed:

-

260r/min

-

Motor power:

-

7.5KW

Quick Details

-

Application:

-

Multi-function

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

IDEAL

-

Dimension(L*W*H):

-

130*100*100cm

-

Weight:

-

1200 KG

-

Product name:

-

Jaw Crusher Machine

-

Raw material:

-

Stones Rocks Ores

-

Function:

-

Mining Crusher Equipment

-

Inlet port size:

-

200*300mm

-

input size:

-

180mm

-

output size:

-

15-50mm

-

Production Capacity:

-

2-6t/h

-

Eccentric shaft speed:

-

260r/min

-

Motor power:

-

7.5KW

Small portable mobile stone crusher diesel engine jaw crusher with screen good price 150x250 mobile jaw crusher

Mobile crusher

station is a full hydraulic drive tracked vehicle chassis with mobile crushing screening equipment. The machine has the advantages of compact structure, reliable performance, beautiful appearance, high automation level. With full hydraulic drive tracked vehicle, optimization with high performance crusher, vibrating screen, electric control cabinet, generators and other equipment, form a complete crushing system. It's widely applicable to the road construction, city building, metallurgy, energy and other departments, for crushing, screening and other operations.

suitable for

stone, limestone, desulfurization slag, granite, aluminum ore, iron furnace slag, iron ore, coal mine, silicon-chrome alloy, construction waste, lapis lazuli, black talc, rock, high carbon ferrochrome, cobblestone, clay, silicon-iron block, limestone, etc.

Products Description

Mobile Impact Crushers are high quality and extremely efficient impact crushers characterized by optimal crushing capacity and superior cubical shaped product production. These mobile crushers are usually used in primary, secondary and tertiary crushing in multistage crushing applications. Moreover, they are usually used in aggregate production, quarrying and recycling applications. Their outstanding overall performance is due to the perfect interaction of all their internal components. Finally, designed to offer efficient and versatile solutions producing a high quality end product.

|

Model

|

IDJ-150*250

|

IDJ-200*300

|

IDJ-200*350

|

IDJ-250*400

|

|

Inlet port size

|

150*250mm

|

200*300mm

|

200*350mm

|

250*400mm

|

|

Input size

|

125mm

|

180mm

|

180mm

|

210mm

|

|

Output size

|

10-40mm

|

15-50mm

|

18-70mm

|

20-60mm

|

|

Production capacity

|

1-3t/h

|

2-6t/h

|

3-10t/h

|

5-20t/h

|

|

Eccentric shaft speed

|

250r/min

|

260r/min

|

260r/min

|

300r/min

|

|

Motor power

|

5.5KW

|

7.5KW

|

11KW

|

15KW

|

|

Weight

|

0.8t

|

1.2t

|

1.5t

|

2.8t

|

|

Model

|

IDJ-400*600

|

IDJ-500*750

|

IDJ-600*900

|

|

Inlet port size

|

400*600mm

|

500*750mm

|

600*900mm

|

|

Input size

|

340mm

|

425mm

|

500mm

|

|

Output size

|

40-100mm

|

50-100mm

|

65-160mm

|

|

Production capacity

|

16-60t/h

|

40-110t/h

|

50-180t/h

|

|

Eccentric shaft speed

|

275r/min

|

275r/min

|

250r/min

|

|

Motor power

|

30KW

|

55KW

|

55-75KW

|

|

Weight

|

7t

|

12t

|

17t

|

Product Overview

Working principle.

1. The motor drives the belt and pulley, which moves the moving jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the support and the moving jaw becomes bigger, thus pushing the moving jaw closer to the fixed jaw.

2. At the same time, the material is crushed or shredded to achieve the purpose of crushing.

3. When the movable jaw goes down, the angle between the bracket and the movable jaw becomes smaller. Under the action of the pull rod and spring, the movable jaw is separated from the fixed jaw. At this time, the crushed material is discharged from the lower opening of the crushing chamber.

4. With the continuous rotation of the motor, the cyclic movement of crushing and manipulation crushes and discharges the material to realize mass production.

1. The motor drives the belt and pulley, which moves the moving jaw up and down through the eccentric shaft. When the moving jaw rises, the angle between the support and the moving jaw becomes bigger, thus pushing the moving jaw closer to the fixed jaw.

2. At the same time, the material is crushed or shredded to achieve the purpose of crushing.

3. When the movable jaw goes down, the angle between the bracket and the movable jaw becomes smaller. Under the action of the pull rod and spring, the movable jaw is separated from the fixed jaw. At this time, the crushed material is discharged from the lower opening of the crushing chamber.

4. With the continuous rotation of the motor, the cyclic movement of crushing and manipulation crushes and discharges the material to realize mass production.

Details Images

Separate welding

Split welded cast steel frame, simple structure, avoid casting defects, strong impact resistance, more solid and reliable.

Discharge port

The adjustment range of discharge opening is large and can meet the needs of different users.

Unique flywheel design, stable and reliable operation

Granite, Basalt, Quartz, Gold Ore, Copper Ore, Iron Ore, River Pebbles, Marble.etc

Main Features

1.Move easily.

It can go to the crushing place directly. It can move not only on the smooth road, but also on the bumpy road.

2.Compact structure and simple operation.

Integrative equipment group with trailer save the working area. With generator, motor and control box on the trailer, it can work outdoor easily. Equipped with supporting facilities, it can be installed quickly and conveniently.

3.Save the cost.

By crushing the materials on site, the transportation cost is reduced.

4.Wide applicability.

The crushing plant can work as independent unit or work with other units to form a primary-secondary crushing system or primary-secondary-fine crushing system. It can also work as a production line with the screening equipment according to the requirement of customers (firstly screening then crushing, or firstly crushing then screening.)

5.Stable performance and convenient maintenance.

Equipped with crushers, vibrating feeders, and vibrating screens, the mobile crushing plant shows high quality and reliable performance. Materials are delivered by belt conveyors, which is simple to operate and easy to maintain. The machine is featured by low investment and high production efficiency.

6.Flexible configuration.

It can be customized according to customers' requirement on working site, materials and particle shape. Examples of customized machines include single units, combined units, units with self-discharged belt conveyors.

Product packaging

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Hot Searches