- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5300

-

Dimension(L*W*H):

-

550x1800x2300

-

Weight:

-

450 KG

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

Short Path Molecular Distillation Equipment

-

Model:

-

GMD-150

-

Type:

-

Wiped Film

-

Sealing:

-

Magnetic Sealing

-

Barrel diameter(mm):

-

150 mm

-

Evaporation Area:

-

0.25 ㎡

-

Process Capacity*:

-

8.0L/HOUR

-

Glass Material:

-

High Borosilicate Glass 3.3

-

Certification:

-

ISO, CE

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

GIOGLASS

-

Voltage:

-

220V/50 HZ

-

Power:

-

5300

-

Dimension(L*W*H):

-

550x1800x2300

-

Weight:

-

450 KG

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

Short Path Molecular Distillation Equipment

-

Model:

-

GMD-150

-

Type:

-

Wiped Film

-

Sealing:

-

Magnetic Sealing

-

Barrel diameter(mm):

-

150 mm

-

Evaporation Area:

-

0.25 ㎡

-

Process Capacity*:

-

8.0L/HOUR

-

Glass Material:

-

High Borosilicate Glass 3.3

-

Certification:

-

ISO, CE

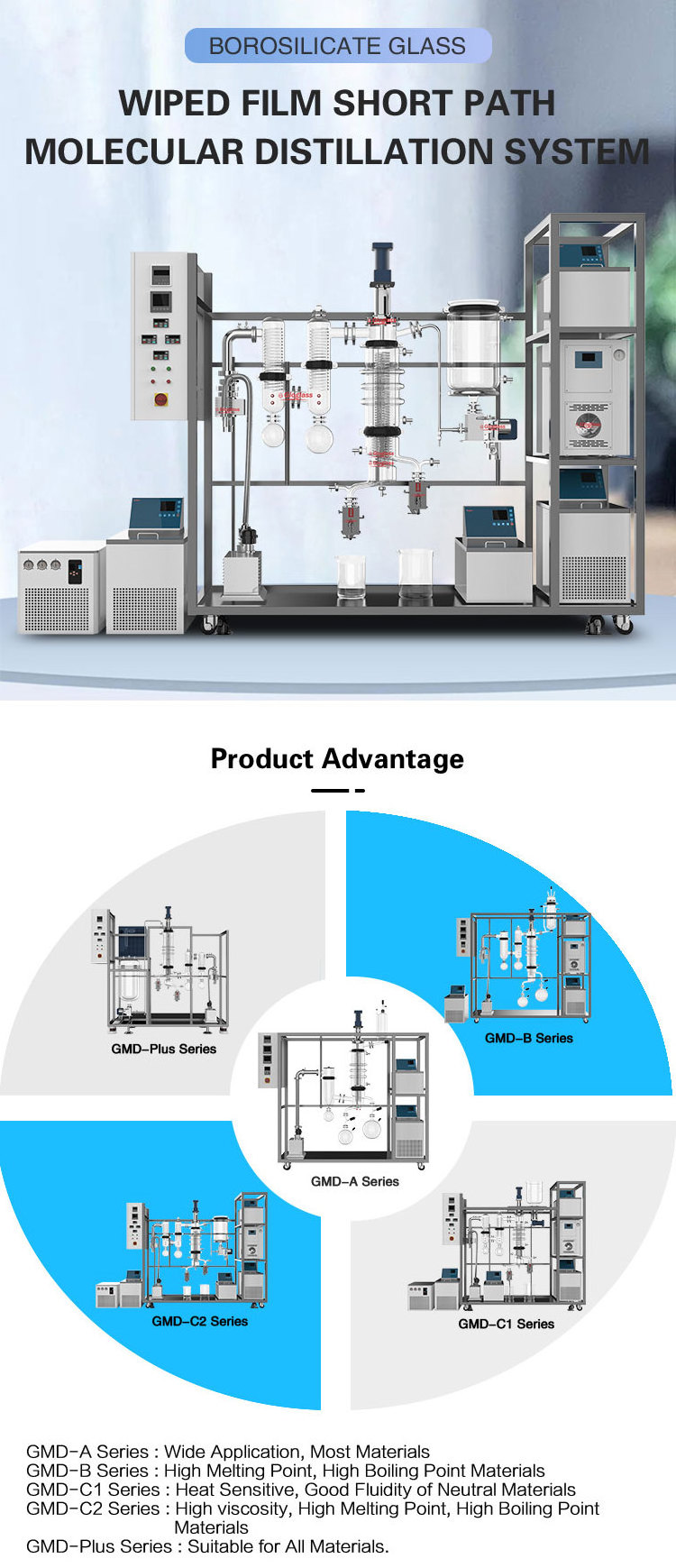

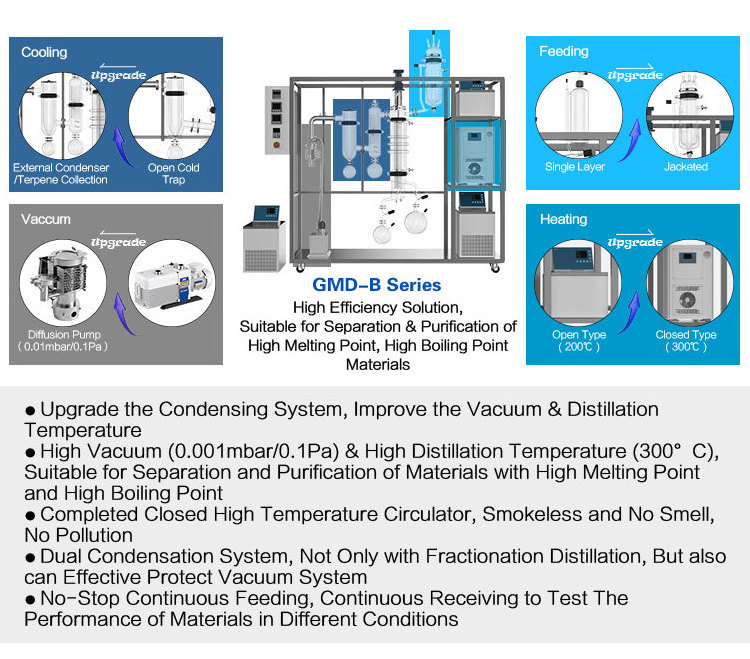

Product Description

Short Path Molecular Distillation is a special liquid-liquid separation technology, which is different from the traditional distillation by boiling point difference principle, but by different substances molecular movement of the average free path difference to achieve separation. So that, in the whole distillation process, material keep its nature and only separate different weight molecule.

When material is fed into the Wiped Film Short Path Molecular Distillation System, through the rotation of the rotor, the wipes will form a very thin film on the wall of the distiller. The smaller molecules will escape and be caught by the inner condenser firstly, and collect as Lighter Phase (Products) .While the bigger molecules flow down the wall of the distiller, and collect as Heavier Phase, which also be known as Residue.

Product Parameter

|

Model

|

GMD-60

|

GMD-80

|

GMD-100

|

GMD-150

|

GMD-200

|

GMD-230

|

|||||

|

Barel Diameter (mm)

|

60

|

80

|

100

|

150

|

200

|

230

|

|||||

|

Effective Evaporation Area (m²)

|

0.06

|

0.1

|

0.15

|

0.25

|

0.35

|

0.5

|

|||||

|

Feeding Rate (kg/h)

|

0.1~2

|

0.1~4

|

0.2~6

|

0.5~8

|

0.5~15

|

0.5~25

|

|||||

|

Feeding Flask Volume (L)

|

1.5

|

1.5

|

1.5

|

2

|

5

|

5

|

|||||

|

Distillate Receiving Flask (L)

|

1

|

1

|

2

|

5

|

10

|

10

|

|||||

|

Residue Receiving Flask (L)

|

1

|

1

|

2

|

5

|

10

|

10

|

|||||

|

Motor Power (W)

|

120

|

120

|

120

|

120

|

120

|

200

|

|||||

|

Rotation Speed (PRM)

|

450

|

450

|

450

|

450

|

300

|

300

|

|||||

|

Designed No-loading Vacuum

|

0.001 mbar

|

|

|

|

|

|

|||||

|

Operation Temperature

|

Up to 300°C

|

|

|

|

|

|

|||||

|

Power Supply

|

220V/50~60Hz (Other Options Can Be Provided)

|

|

|

|

|

|

|||||

Hot Searches