Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

90

-

Weight:

-

400 KG

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

68 rpm

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

90

-

Weight:

-

400 KG

Our quality journey starts from an idea and never ends

The manufacture solutions that we provide, either production lines or services, are designed and developed by our team of experts with one priority, to add value to our partners. We believe that in order for a product to be able to add value, it has to be produced with the highest quality standards, in every step of the process, from design and production to delivery, training and after sales support.

To achieve and maintain our high-quality standards, we have developed the Quality Excellence process.

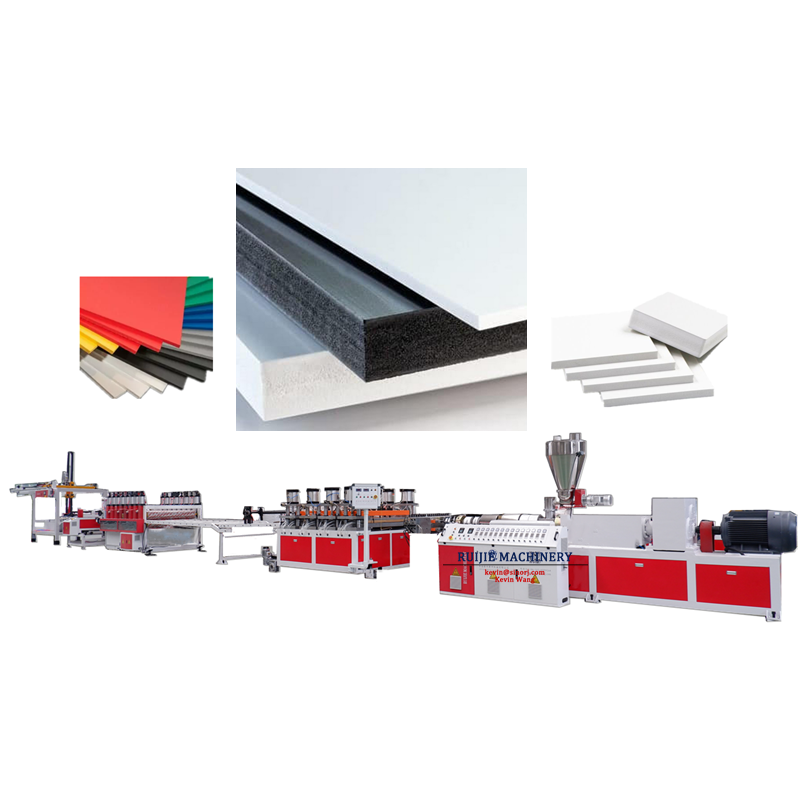

Advantages of PVC Foam Board

1. Lightweight for Effortless Handling and Installation

The density of standard PVC foam board typically ranges from 0.5 to 0.65g/cm3, which is less than half that of solid PVC sheets and comparable to some wood panels. This lightweight property ensures easy handling and straightforward installation.

2. Water and Moisture Resistance

PVC foam board exhibits minimal water absorption, making it highly resistant to water and moisture. This quality proves invaluable in humid environments.

3. Corrosion Resistance

Polyvinyl chloride boasts resistance to acids, alkalis, and a range of chemicals, mitigating concerns about corrosion or rust in practical applications.

4. Termite and White Ant Resistance

PVC foam board is unappealing to termites and white ants, rendering indoor furniture crafted from it unattractive to these pests.

5. Self-Extinguishing Fire Resistance

Common PVC foam board possesses self-extinguishing properties in fire conditions. Fireproof reinforcement variants can even meet ASTM E84 Class A standards.

6. UV Resistance

PVC foam boards, compared to wooden counterparts, resist crushing and cracking in outdoor use, contributing to a longer service life. UV-resistant variants perform exceptionally well, especially when enhanced with anti-ultraviolet agents.

7. High Strength

Depending on its density, PVC foam board can exhibit remarkable rigidity or flexibility, catering to varying strength requirements.

8. Ease of Processing

PVC foam board can be conveniently drilled, nailed, sawed, CNC cut, hot bent, laminated, sanded, and painted without the need for specialized equipment or tools.

This process enables us to constantly offer manufacture solutions of the highest quality, since we never stop evolving our design, development and production processes, which enhance our product portfolio. We put to the test all our ideas no matter how bold or complex may seem, in order to convert them into the optimum possible solution for our partners.

A Business Opportunity

We offer to our partners the opportunity to enter the popular product market.

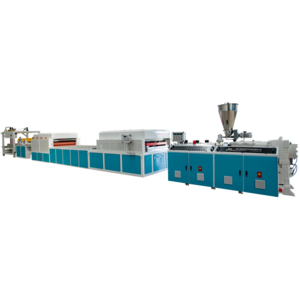

|

No. |

Name of Equipment |

Q TY |

|

1 |

SJSZ80/156 Conical Twin-screw extrusion machine |

1set |

|

2 |

SJSZ65/132 Conical Twin-screw extrusion machine |

1set |

|

3 |

Mould( 4 -2 4 mm) |

1set |

|

4 |

Distributor |

1set |

|

5 |

Calibrating Platform |

1set |

|

6 |

Cooling Bracket |

1set |

|

7 |

Hauling Off Machine with protection film laminator |

1set |

|

8 |

Oil temperature controller |

1set |

|

9 |

Edge Cutting Machine with dust collection |

1set |

|

10 |

Across Cutting Machine |

1set |

|

11 |

Auto- Stacker |

1set |

SJSZ80/156 twin-screw extru sion machine

Extruder SJSZ80/156

Output 50 0- 70 0kg/h

Max. width of board 1240mm

AC Motor 75Kw Siemens Standard brand

Hopper Material Stainless Steel

Vacuum pump 2.2kw

Output 400-450kg/h

SJSZ 65 /1 32 twin-screw extru sion machine

Extruder SJSZ65/132

AC Motor 37Kw Siemens Beide brand

Hopper Material Stainless Steel

Vacuum pump 2.2kw

Output 160-180kg/h

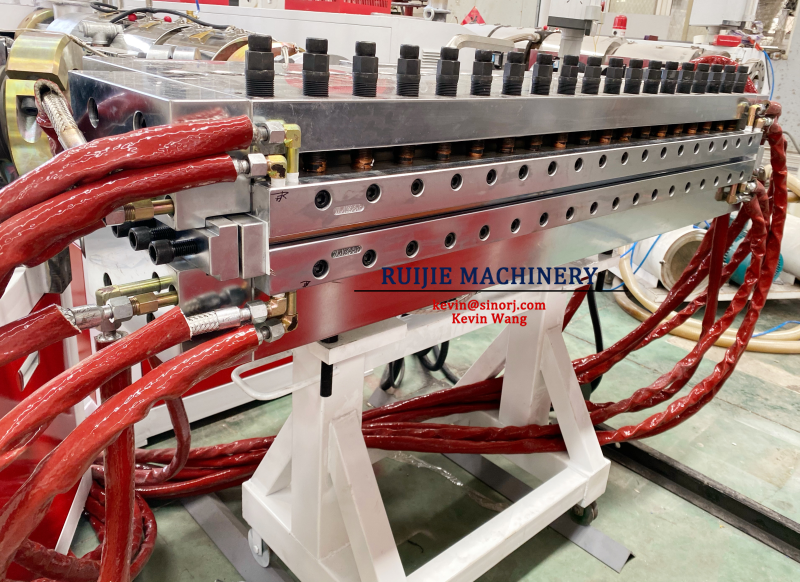

Mould with Distributor

Mould Type. T type Mould

Material 2311A

Product Width 1240mm

Width of mould mouth Interior heating ,heating pipe

Adjusting Scope of mould Mouth 4-24mm

Heating of mould head 24kw(inner heating)

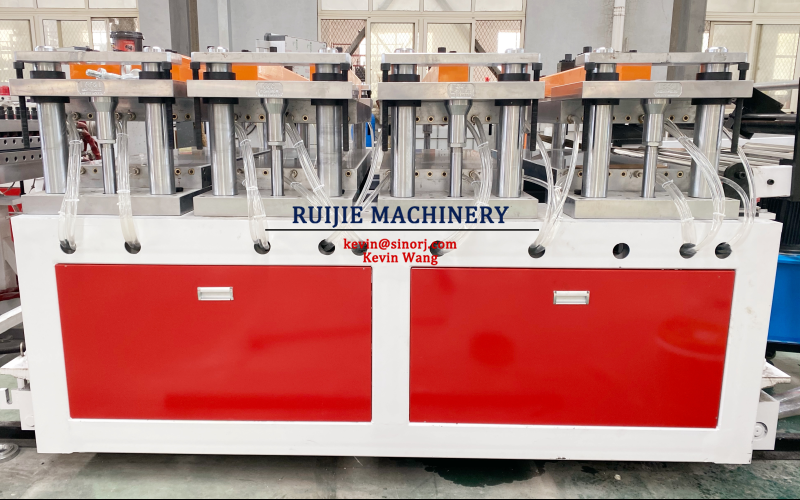

Calibrating platform

Calibrating plates No. 4 pairs

Calibrating Medium water

Plate Move Type Up and Down

Plate Move Mode Hydraulic

Cooling Bracket

Specification 60×1400

Quantity of Rollers 10

Material of Rollers stainless steel Roller

Hauling Off Machine with protection film laminator

Quantities of Rubber Rollers 8 pairs

Specification 248×1500

Power of Motor 7.5 kw×2

Board Cutting Edge Machine with dust collection

Motor Power 1.5kw*2

Move Type By hand

Move Range 500mm

Suck Scrap Two Fans

Auto- Stacker

Camping plate width/length 1200mm*2400mm

Camping Plate thickness 3mm-30mm

Stacking height 1000mm

Who we are

By utilizing our knowledge, experience and expertise we offer the most advanced solutions for the manufacture industry worldwide.

What we do

We are moving forward to be a global leader in designing and developing comprehensive solutions for manufature industry. By utilizing our knowledge experience and expertise, we offer turnkey custom-made solutions for all manufacturing processes involved in manufature.

Why we do it

We are active in the most advanced and fastest growing segment of the manufacture industry. The vast population growth leads to constantly increasing needs .

Building partnerships wherever you grow

All successful projects start with successful relationships. Partnering with us means forming a long-term connection with real people that join you from the ground up, and stay with you even after you’ve reached your goal. It’s these relationships that directly lead to better results - faster ROI, better yields, and lasting success.

From idea to execution

Whether you need technical guidance or comprehensive, end-to-end project management, we are equipped to deliver the ingredients you need to produce a successful manufa c ture project.

Production Lines

We are moving forward to be a global leader in developing state of the art production lines for the maunfacture industry.

We combine the knowledge, experience and expertise of our R&J department with the cutting-edge technology to deliver the best possible solution. The manufacturing of our production lines is conducted according to proprietary mechanical designs perfected by continuous strive for excellence and upgrade. Our dedicated in-house R&J software department designs, develops and constantly upgrades the software of our production lines. The electrical design and panel construction takes place in the new modern facilities of R.J. with high tech precision and testing equipment.

FAQ :

Q: Why do I choose your company?

A: 1) We are one of the leading manufacturers of extruder machinery .

2) Our company has made extruder machine about 14 years with strong experience and advanced technology.

3) Best Quality & Best Service with Competitive price. 1 year guarantee and lifetime maintenance.

4) We have Professional technical teams, and will supply 24 hours services.

Q: What should we prepare for Machine ?

A:You should prepare raw material, workshop, water line, electric line, compress air(if you need I can help you buy air

compressor).We would supply workshop layout drawing for you.

Q: Where is your factory located? How can I visit you?

A: Our factory is located in Qingdao city, Shandong province, you can fly to Qingdao AirPort. When you confirm the flight No. and time, please tell me then we will pick you up at Airport.

Q: If my machine can not work when I receive it, what will your factory do?

A: First of all, do not worry about the thing, we will test the machine before shipment. And if it happened, we will send our

engineer to your factory to repair the machine.

Q: How can I believe your factory and machines.

A: We have CE, ISO certificates. And we have customers all around the world, we can test the machine after it finished for your checking, if it do not reach your demands, we will change, or even give back your deposit.