- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

AC380v

-

Dimension(L*W*H):

-

1100X1300X2200mm

-

Weight (KG):

-

300

-

Power (kW):

-

4

-

Product name:

-

EDM Drilling Hole Machines

-

Key word:

-

CNC EDM drilling hole machine

-

Function:

-

Metal Processing

-

Color:

-

Optional

-

Power Consumption:

-

4kw

-

Brand:

-

Randro

-

Product type:

-

Edm Drilling Machine

-

Precision:

-

0.015mm

-

Worktable travel (mm):

-

800*500

-

Application:

-

Metal Machining

Quick Details

-

Marketing Type:

-

New Product

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Randro

-

Voltage:

-

AC380v

-

Dimension(L*W*H):

-

1100X1300X2200mm

-

Weight (KG):

-

300

-

Power (kW):

-

4

-

Product name:

-

EDM Drilling Hole Machines

-

Key word:

-

CNC EDM drilling hole machine

-

Function:

-

Metal Processing

-

Color:

-

Optional

-

Power Consumption:

-

4kw

-

Brand:

-

Randro

-

Product type:

-

Edm Drilling Machine

-

Precision:

-

0.015mm

-

Worktable travel (mm):

-

800*500

-

Application:

-

Metal Machining

Products Description

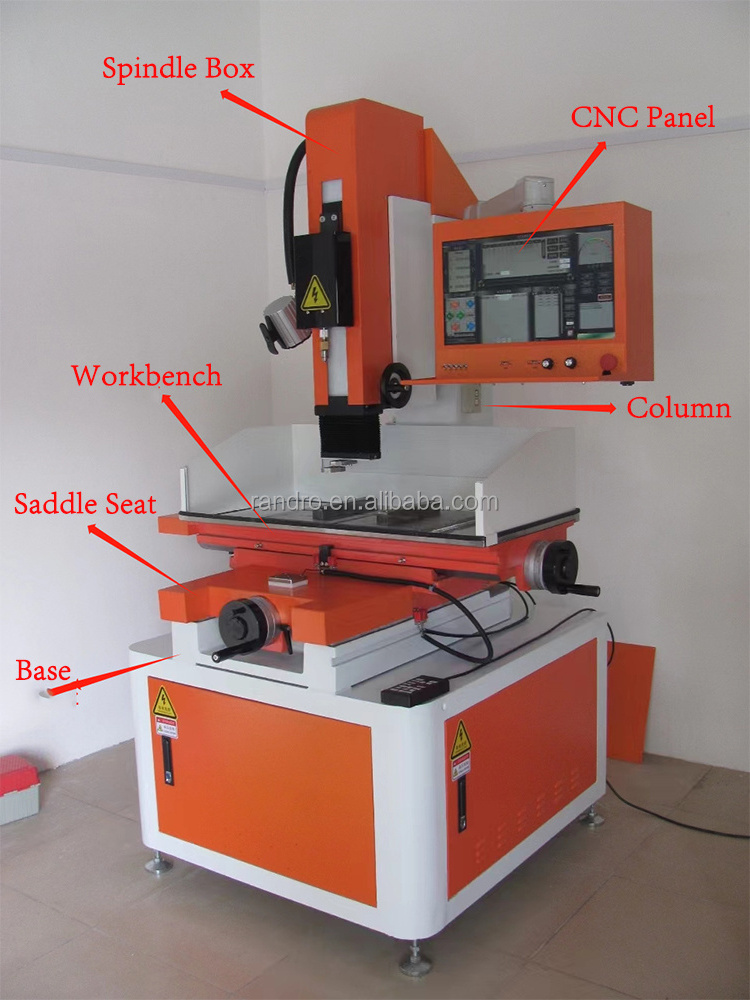

Randro CNC EDM Drilling Hole Machine:

Spark erosion drilling machine refers to an electric discharge machining machine that uses the principle of electric discharge machining to process holes with dimensions less than 5mm. Used for processing small and medium-sized stamping dies, its processing feature is not limited by the hardness of metal materials. The template can be quenched first and then processed with this machine to ensure quality and improve service life. The tool electrode material can be made of steel, cast iron, or copper.

1.Suitable for processing various conductive materials such as stainless steel, hardened steel, cemented carbide, copper, aluminum, etc.

2.The main shaft is equipped with a precision servo motor, which can be raised and lowered quickly and has good perforation stability.

3.Low power consumption, the processing aperture is 0.15-3mm, and the maximum aspect ratio can reach more than 300mm

4.High power consumption, processing speed up to 30-60mm/min

5.Penetrate directly from the inclined surface and curved surface; directly use tap water as the working fluid, and can use the circulating water tank for recycling

6.According to user requirements, the machine can be configured as a multi-axis CNC or digital display machine

Characteristics of Electric Spark Drilling Hole Machine

1. Suitable for processing various conductive materials such as stainless steel, quenched steel, hard alloy, copper, aluminum, etc.

2. Machining aperture Φ 0.3~ Φ 3.0mm, with a maximum depth to diameter ratio of over 200:1.

3. The processing speed can reach a maximum of 20-60mm per minute.

4. Directly penetrate from the inclined surface or curved surface using tap water as the working fluid.

5. The X, Y, and Z axes of the workbench are equipped with digital display devices.

6. Equipped with automatic electrode trimming function.

7. The spindle lifting has a fast up and down function.

8. Equipped with adjustable processing voltage function.

9. Equipped with edge positioning function.

Product Application

The discharge between the electrode and the metal generates high-temperature corrosion of the metal to achieve the purpose of perforation, which is used for processing fine holes in superhard steel, hard alloys, copper, aluminum, and any conductive substance. It can process small holes with a minimum diameter of 0.015mm and can also process small holes with tapers.

It is widely used in precision mold processing and is generally used as a supporting equipment for electric discharge wire cutting machines. It is used for threading holes, chemical fiber nozzles, spinneret holes of spinnerets, filter plates, sieve plates, engine blades, heat dissipation holes of cylinder bodies, oil and air passage holes of hydraulic and pneumatic valve bodies, etc.

Product Parameters

|

Product Name:

|

CNC Edm Drilling Machine

|

|

|

|

Model of machine tool:

|

GD300CNC

|

GD450CNC

|

|

|

Worktable stroke:

|

800× 500mm

|

900mm×500mm

|

|

|

X, Y-axis travel:

|

400X300mm

|

450X350mm

|

|

|

spindle servo stroke

|

350mm

|

350mm

|

|

|

Maximum processing current:

|

30A

|

30A

|

|

|

Maximum processing thickness

|

350mm

|

400mm

|

|

|

Maximum processing weight

|

300KG

|

400KG

|

|

|

Machine tool consumption power

|

4kw

|

4kw

|

|

|

electrode wire diameter

|

Φ 0.15 to Φ 3mm

|

Φ0.15~Φ3mm

|

|

|

Net weight

|

500KG

|

850KG

|

|

|

Programming Method

|

Manual/CAD Input

|

Manual/CAD Input

|

|

|

Minimum movement equivalent

|

0.001mm

|

0.001mm

|

|

|

Input voltage

|

AC380V (customizable)

|

AC380V(customizable)

|

|

|

Overall dimensions

|

1100×1100×1800mm

|

1100X1300X2200mm

|

|

Hot Searches