- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

10000000tons/year

-

Dimension(L*W*H):

-

40x30x18cm

-

Power:

-

/

-

Voltage:

-

/

-

Weight (KG):

-

21

-

Core Components:

-

TEE, others

-

Product name:

-

Expansive mortar

-

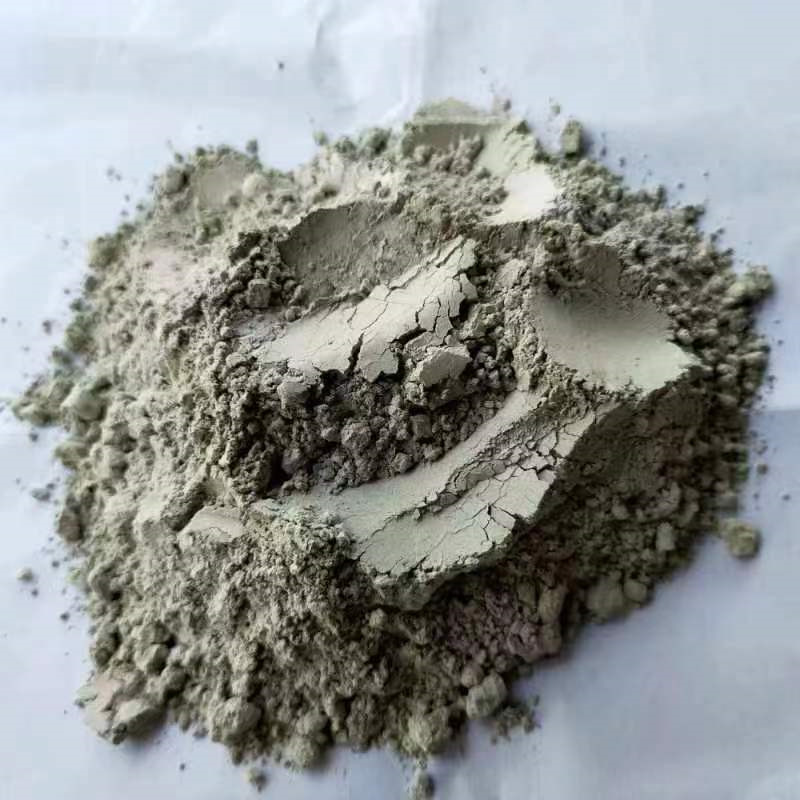

Color:

-

Gray

-

Material:

-

Calcium Oxide

-

Odour:

-

Inodourous

-

Denstity:

-

3.2-3.4g per cm3

-

Usable temperature:

-

-5°C-40°C

-

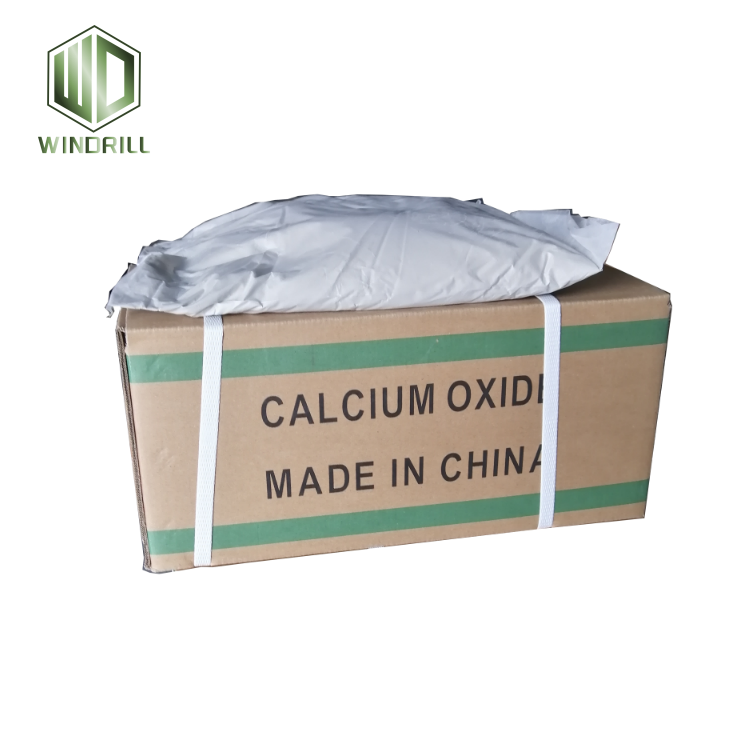

Packing:

-

Bag / Carton / Wooden pallet

-

HS Code:

-

3824909990

-

EINECS No.:

-

215-137-3

-

Usage:

-

Stone, rock & blocks cutting and Concrete demolition

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Win Drill

-

Application:

-

Stone crack Demolition construction

-

Production Capacity:

-

10000000tons/year

-

Dimension(L*W*H):

-

40x30x18cm

-

Power:

-

/

-

Voltage:

-

/

-

Weight (KG):

-

21

-

Core Components:

-

TEE, others

-

Product name:

-

Expansive mortar

-

Color:

-

Gray

-

Material:

-

Calcium Oxide

-

Odour:

-

Inodourous

-

Denstity:

-

3.2-3.4g per cm3

-

Usable temperature:

-

-5°C-40°C

-

Packing:

-

Bag / Carton / Wooden pallet

-

HS Code:

-

3824909990

-

EINECS No.:

-

215-137-3

-

Usage:

-

Stone, rock & blocks cutting and Concrete demolition

Expansive mortar Non explosive rock cracking powder Demolition agents

What is Expansive cement?

Expansive cement is a kind of powder with high expansion force. The main material of Expansive cement is Calcium oxide. It is also known as Expansive mortar, Non explosive cracking powder, Expansive demolition, Rock spliltting mortar, High-efficient soundless cracking agent, Expansive malt, Expanding cement, Demolition agent and various combinations and permutations of the above.

Expansive cement doing good job at stone and reinforced concrete break, cut and demolish quietly, easily and safely. No explosive, no noise, no vibrations no dust.

Depending on different environmental temperatures, there are 4 types of Expansive cement for your choice.

| Type | Usable ambient temperature |

| SCA-4 | 40℃-50℃ ( 104℉-122℉) |

| SCA-1 | 25℃-40℃ ( 77℉-104℉) |

| SCA-2 | 10℃-25℃ ( 50℉-77℉) |

| SCA-3 | -5℃-10℃ ( 23℉-50℉) |

Benifits

Controllable fragmentation

Evironmentally friendly

High efficiency

Easy to use

Economy

Safety

No dust

No noice

No vibration

No toxic fumes

No flying debris

No special permit

How to use

Drilling

1. Drill holes using an rock drilling machine and appropriate drill bit specific to the rock type.

2. Holes should be driled no further than 30-60cm (1ft-2ft) apart. Note: in reinforced concrete recommended no more than 20cm (8") apart.

3. Recommended hole diameter 38mm - 50mm (1 1/2" -2"). Depth would be 70-90% of the way depending on the type of rock/material to be removed.

*Hole and Row Distance Space Chart

|

Rock hardness |

F=4 |

F=6 |

F=8 |

F=12 |

Plain |

Reinforce |

|

Hole dis.(cm) |

50-100 |

40 |

30 |

20 |

30 |

20 |

|

Row dis.(cm) |

80 |

50 |

40 |

30 |

40 |

30 |

*Cracking Design Reference Chart ( unit:cm )

|

Cracking body |

Hole Depth |

Hole Space |

Row Space |

Hole Diameter |

Kg/m 3 |

|

Soft hard rock |

100% |

40-100 |

(0.6-0.9)a |

30-40 |

5-10 |

|

Middle hard rock |

105% |

30-40 |

(0.6-0.9)a |

38-42 |

12-22 |

|

Hard granite |

105% |

25-40 |

30-80 |

38-42 |

18-25 |

|

Rock cracking |

75% |

20-40 |

(0.6-0.9)a |

30-40 |

12-18 |

|

Plain concrete |

80-85% |

20-30 |

(0.6-0.9)a |

38-42 |

12-18 |

|

Reinforce concrete and special break |

90%-95% |

15-30 |

(0.6-0.9)a |

38-50 |

18-25 |

Mixing

1. For regular safety reasons and mixing small amounts by hand, it is recommended to use rubber gloves

2. In a bucket, combine 1.5 Liters of normal water to one 5kgs bag of Expansive cement or pour water and Expansive cement as a rate of 1:3units by weight.

3. Mix well, using a drill and paddle is recommended. lf mixing with a stick or other method, make sure powder is completely dissolved into the water. Mix to a slurry.

Filling

1. Clean holes before filling using air hose remove excess dust from drilling

2. Expansive cement slurry should be poured into holes within 10-15 min after mixing. Do not fill up the holes with the slurry, only fill the holes about 15mm ( 1/2" to 1") from the top.

3. Mix well and pour into holes while agitating the hole to make sure no air gaps are in the hole. Example: Using a piece of rod orstick to poke holes.

4. For Horizontal holes, a grouting pump would be most reliable to poor

Cracking

The cracks appear in 40-60 min. after filing, depending on the weather,rocks, and concrete type. The cracks become wider within time (maximun 48 hours expanding time). If small crack is found, you can pour more water in crack line for more expanding, Cracking gap would be 3-5 cm, and then carry out demolition work.

Consumption