- Product Details

- {{item.text}}

Quick Details

-

Coil Number:

-

3

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZBB

-

Model Number:

-

HTDSPZ and ZPS

-

onput Voltageto:

-

OTHER,10.5kv

Quick Details

-

Usage:

-

Electric furnaces.rectifier systems

-

Phase:

-

3

-

Coil Structure:

-

TOROIDAL

-

Coil Number:

-

3

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZBB

-

Model Number:

-

HTDSPZ and ZPS

-

onput Voltageto:

-

OTHER,10.5kv

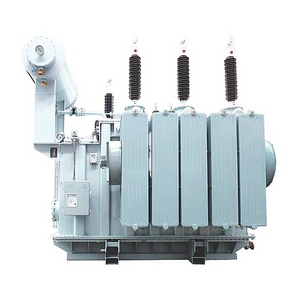

|

Rated Power(kva)

|

High Voltage(kV)

|

H.V.Tap range

|

Low Voltage(kV)

|

Connection symbol

|

Short Circuit Impendance

|

No-load loss(kw)

|

On-load loss(kw)

|

No-load current (%)

|

|

6300

|

63

66 69 110 132 138 220 or others |

±8×1.25%

or others |

6.3

6.6 10.5 11 33 69 or others |

YNd11

YNyn0 or others |

10-14

|

9.4

|

34

|

0.63

|

|

8000

|

|

|

|

|

|

11.2

|

40.4

|

0.63

|

|

10000

|

|

|

|

|

|

13.1

|

47.6

|

0.75

|

|

12500

|

|

|

|

|

|

15.4

|

56.5

|

0.53

|

|

16000

|

|

|

|

|

|

18.5

|

69.5

|

0.49

|

|

20000

|

|

|

|

|

|

21.8

|

84.2

|

0.49

|

|

25000

|

|

|

|

|

|

25.6

|

99.5

|

0.4

|

|

31500

|

|

|

|

|

|

30.4

|

120

|

0.4

|

|

40000

|

|

|

|

|

|

36.2

|

140.3

|

0.39

|

|

50000

|

|

|

|

|

|

42.6

|

174.3

|

0.39

|

|

63000

|

|

|

|

|

|

52

|

210

|

0.39

|

|

75000

|

|

|

|

|

|

60

|

238

|

0.49

|

|

90000

|

|

|

|

|

|

69

|

274

|

0.49

|

|

120000

|

|

|

|

|

|

85

|

328

|

0.46

|

|

150000

|

|

|

|

|

|

101

|

385

|

0.42

|

|

160000

|

|

|

|

|

|

105

|

404

|

0.42

|

|

180000

|

|

|

|

|

|

115

|

436

|

0.42

|

|

240000

|

|

|

|

|

|

144

|

539

|

0.4

|

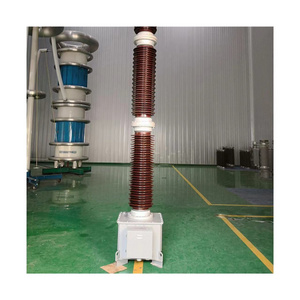

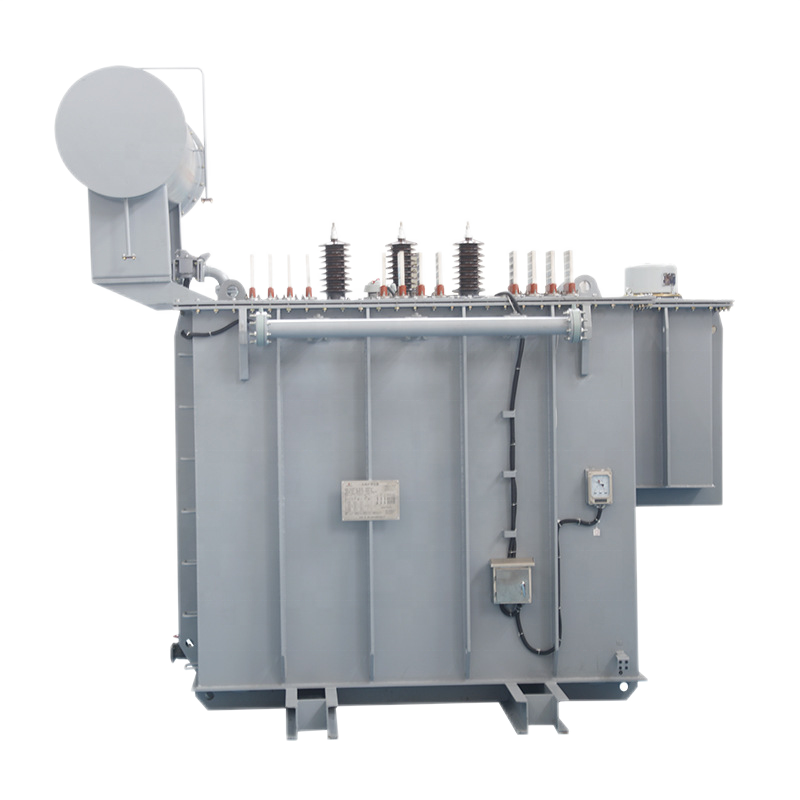

Rectifier transformer

Widely used in lighting, machine tools, mechanical electronic equipment, medical devices, rectifiers, and other applications. The product's performance can meet various special requirements of users.

1. Electrochemical Industry This is the industry where rectifiers are most commonly used. It is used in the electrolysis of compounds to produce non-ferrous metals such as aluminum, magnesium, copper, and other metals. It is also used in the electrolysis of salt to produce chlorine and alkali. Additionally, it is used in the electrolysis of water to produce hydrogen and oxygen.

2. Traction DC Power Supply Used in the direct current grid for mining or urban electric locomotives. Due to the overhead lines on the valve side and the frequent short-circuit faults, the direct current load varies greatly, and electric locomotives start frequently, causing varying degrees of short-term overload.Therefore, the

temperature rise limit and current density of such transformers are relatively low

. The

impedance is about 30%higher than that of corresponding power transformers.

3. Direct Current Power for Transmission Mainly used to power direct current motors in power transmission, such as the armature and excitation of rolling mills.

4. Direct Current Transmission The voltage of this type of rectifier transformer is generally above 110kV, with a capacity of several tens of kVA. Special attention needs to be paid to the insulation problem between the ground and the DC and AC overlaid. Additionally, there are applications for electroplating or electrical processing, excitation, charging, and electrostatic dust removal.

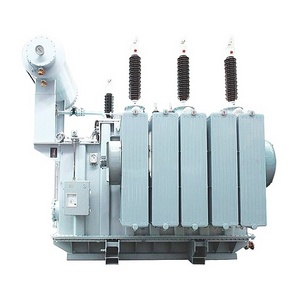

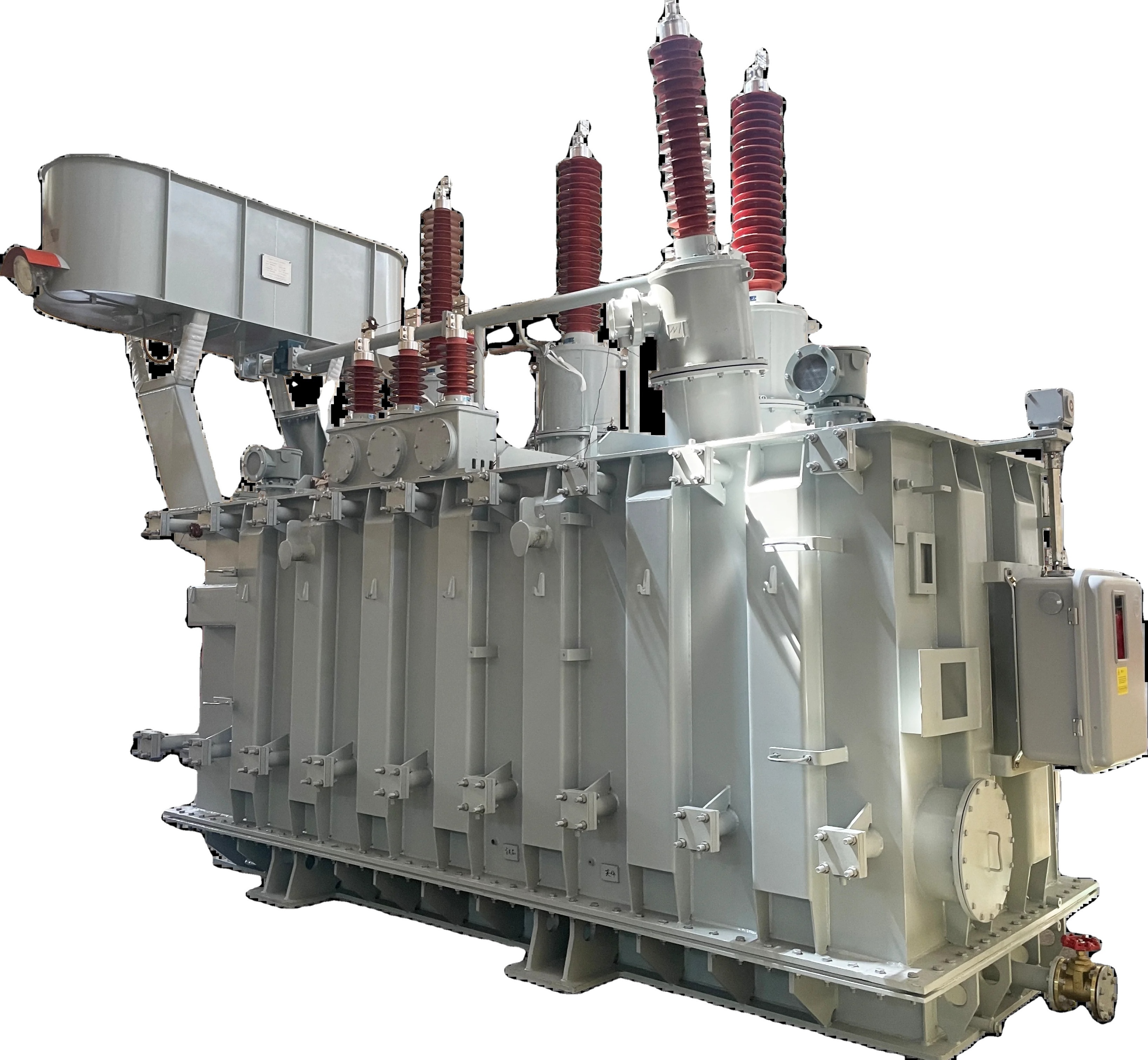

Electric furnace transformer

These are resistive furnaces and salt bath furnaces transformers , Due to the low resistance of the heating element or significant resistance changes during the heating process, a resistive furnace transformer is required between the furnace and the power grid to reduce and regulate the input voltage of the electric furnace. Resistive furnace transformers with small and medium capacities (from hundreds to thousands of kVA) are usually oil-immersed self-cooling transformers, while those with large capacities are forced oil circulation water-cooled transformers. High-capacity electric furnace transformers have complex structures and high technical requirements. Their

secondary voltage is low

, typically ranging from tens of volts to hundreds of volts, and they need to be adjustable within a wide range. The secondary current often reaches thousands to tens of thousands of amperes. In addition, in steelmaking, the melting period requires high power, and the transformer is expected to have a

20% overload capacity within 2 hours

. In the steelmaking process, the collapse of furnace materials can easily cause electrode short-circuits, so it is necessary to connect a current-limiting reactor on the primary side of the arc furnace transformer or design it to have a significant

impedance to restrict short-circuit currents.

Hot Searches