- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Power:

-

12.KW

-

Dimension(L*W*H):

-

2700*1600*2000mm

-

Weight:

-

3200 kg

-

Marketing Type:

-

New Product 2021

-

Paper Cup Size::

-

2 ~16 OZ

-

Rated Productivity:

-

50-60pcs/min

-

Suitable paper weight::

-

170~320gsm

-

GW:

-

3300KGS

-

NW:

-

3200KGS

-

Cup Side Welding::

-

Ultrasonic heater

-

After Warranty Service:

-

Video technical support

Quick Details

-

Production Capacity:

-

50-60pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Mingyuan

-

Voltage:

-

380V/220V

-

Power:

-

12.KW

-

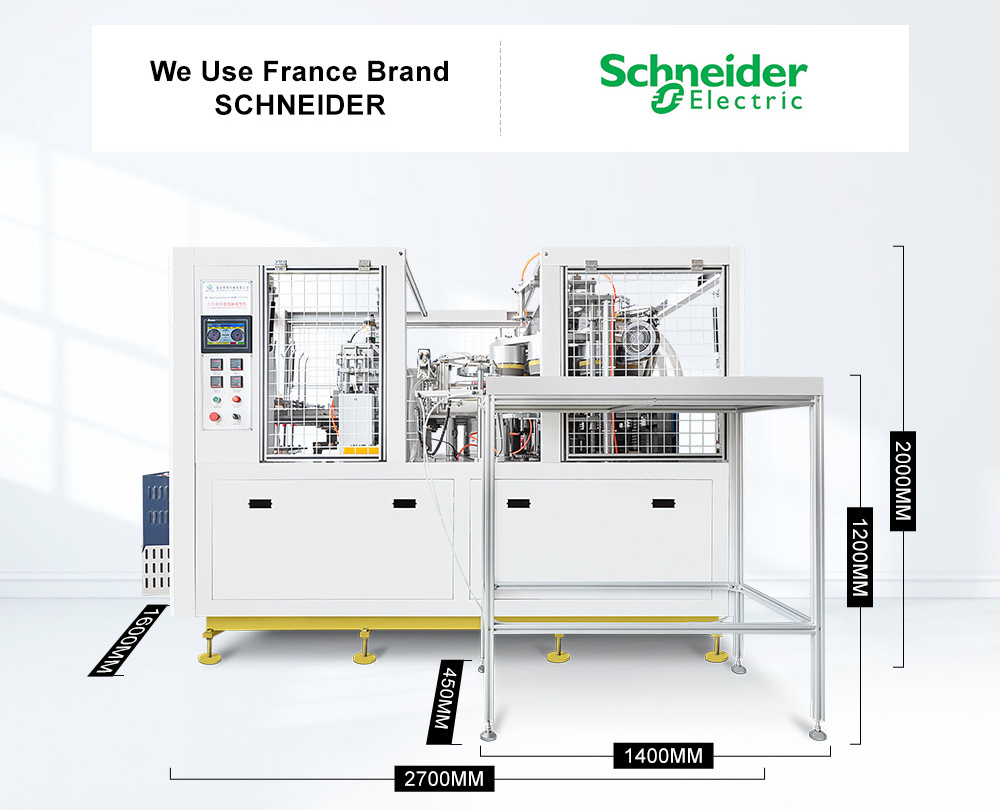

Dimension(L*W*H):

-

2700*1600*2000mm

-

Weight:

-

3200 kg

-

Marketing Type:

-

New Product 2021

-

Paper Cup Size::

-

2 ~16 OZ

-

Rated Productivity:

-

50-60pcs/min

-

Suitable paper weight::

-

170~320gsm

-

GW:

-

3300KGS

-

NW:

-

3200KGS

-

Cup Side Welding::

-

Ultrasonic heater

-

After Warranty Service:

-

Video technical support

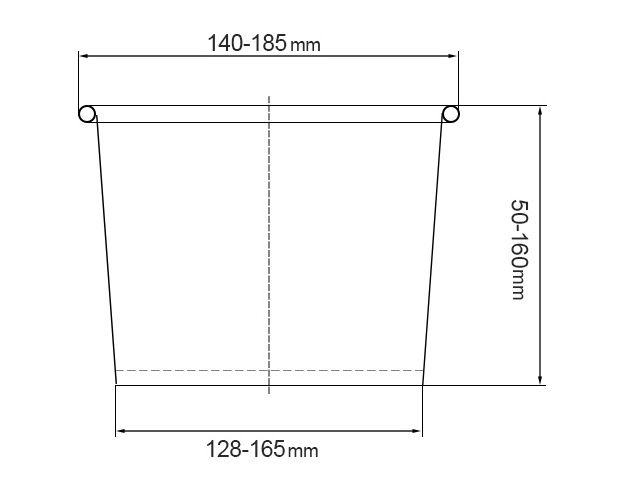

Paper bucket size

|

Cup Bottom Diameter:

|

|

|

|

Min128mm~Max165mm

|

|

|

|

Cup Top Diameter:

|

|

|

|

Min

140mm~Max185mm

|

|

|

|

Cup Height:

|

|

|

|

Min50mm~Max160mm

|

|

|

|

Bottom Knurling Depth:

|

|

|

|

Min4mm~Max 12mm

|

|

|

|

Top Curling Rim Diameter:

|

|

|

|

Popular about 2.54Φ~4Φ

|

|

|

We can also provide special sized paper bucket machine for your needs.

Products Description

1.High-speed production capacity: speed is 50-60 pcs each min, Cup size range is from 500-1800ML,

greatly improving production efficiency.

2.Multi-size applicability: It can finish the whole process including paper feeding, side sealing , cup bottom punching & feeding, hot air bottom heating , knurling, cup-top curling ,cup stacking.

3.A very unique system:Machine is equipped with PLC control system and failure sensor detecting system to detect abnormal work, and improves the stability and life of the machine.

4.Precise and stable operation:The automatic oil lubrication system guarantees all mechanical parts to work more smoothly .

5.The above are the characteristics of JBZ-OC paper buket forming machine: Its high-speed production capacity is large, it can handle a variety of paper bucket sizes, the operation is precise and stable, and the bottom performance is excellent and sealed,making it an ideal choice for paper bucket production.

2.Multi-size applicability: It can finish the whole process including paper feeding, side sealing , cup bottom punching & feeding, hot air bottom heating , knurling, cup-top curling ,cup stacking.

3.A very unique system:Machine is equipped with PLC control system and failure sensor detecting system to detect abnormal work, and improves the stability and life of the machine.

4.Precise and stable operation:The automatic oil lubrication system guarantees all mechanical parts to work more smoothly .

5.The above are the characteristics of JBZ-OC paper buket forming machine: Its high-speed production capacity is large, it can handle a variety of paper bucket sizes, the operation is precise and stable, and the bottom performance is excellent and sealed,making it an ideal choice for paper bucket production.

|

Model

|

JBZ-0CBUCKET 185 Salad Paper Bowl Forming Machine

|

|

|

|

||||

|

Paper bucket Size

|

Top dia :140-185mm Height:50-160mm Bottom dia 128-165

|

|

|

|

||||

|

Raw Material

|

Single/Double PE paper

|

|

|

|

||||

|

Suitable Paper Weight

|

170-320g/m2

|

|

|

|

||||

|

Speed

|

50-60 Pcs/min

|

|

|

|

||||

|

Total Power

|

50/60HZ, 380v ( better use 380v, 3 Phase ) or special Power requirements

|

|

|

|

||||

|

Total Weight

|

3200KG

|

|

|

|

||||

|

General motors

|

2.2KW

|

|

|

|

||||

|

Package Size(L*W*H)

|

2700x1600x2000mm

|

|

|

|

||||

|

Packing

|

Seaworthy Wooden Case

|

|

|

|

||||

|

Air Source Specification

|

0.5-0.8MPA,0.4:6m3/min

|

|

|

|

||||

|

OEM ( Show Client Company Name in Machine Panel ) is welcome in our factory

|

|

|

|

|

||||

product details

Selling Points

Quality Brand electric System like Delta, Schneider. PLC control system be with Delta Brand Made in Japan with Reliable quality.

Automatic oil lubrication system

The whole machine adopts automatic oil lubrication system(oil circulation system is including oil motor filter, copper pipe)which makes all gear moving parts working at high speed more smoothly and greatly improve the service life of spare parts.

Servo Motor Paper Feeding Unit

The bottom paper feeding is controlled by the servo motor which is more accurate and stable.

Main Motor

The big and strong gear is driven by the main motor better quality and more stable.

Company Strength

Rui'an Mingyuan Machinery Co., Ltd. was established in 2009 and specializes in manufacturing paper product making machines and packaging equipment. Our business covers research and development, production, sales, and service.To meet the needs of our customers, we provide solutions, high-quality equipment, and excellent after-sales service based on their requirements. Through continuous innovation and hard work, we help our customers succeed in the competitive market.

FREE TOOLS,REPLACEABLE PARTS

we supply more replaceable parts to client to replace the broken spare parts and help client save money and time to buy it

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Hot Searches