- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LIYI

-

Dimension(L*W*H):

-

1200*620*550mm

-

Weight:

-

120 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Maximum coating width:

-

280mm

-

Dimension:

-

1200*620*550mm(L*W*H)

-

Coating speed:

-

adjustable

-

Power source:

-

1 phase, AC 220V/330V

-

Package Type:

-

Film

-

Certificate:

-

CE ISO

Quick Details

-

Applicable Industries:

-

lab use

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIYI

-

Dimension(L*W*H):

-

1200*620*550mm

-

Weight:

-

120 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Maximum coating width:

-

280mm

-

Dimension:

-

1200*620*550mm(L*W*H)

-

Coating speed:

-

adjustable

-

Power source:

-

1 phase, AC 220V/330V

-

Package Type:

-

Film

-

Certificate:

-

CE ISO

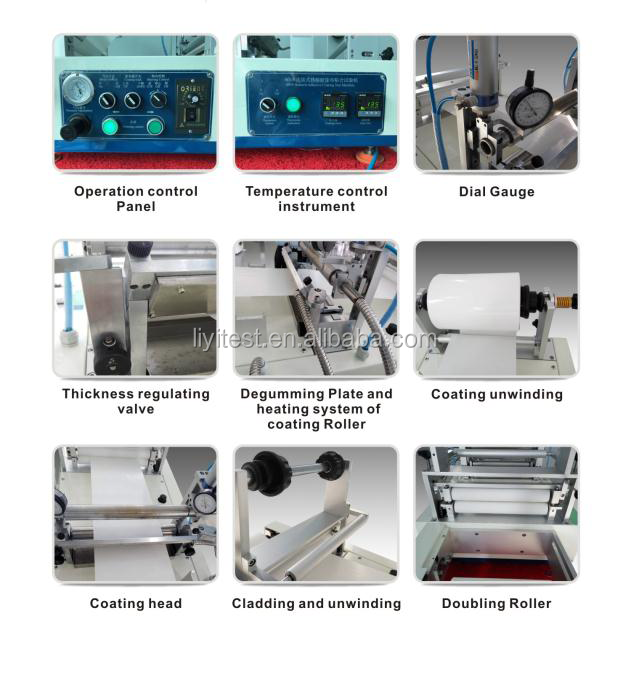

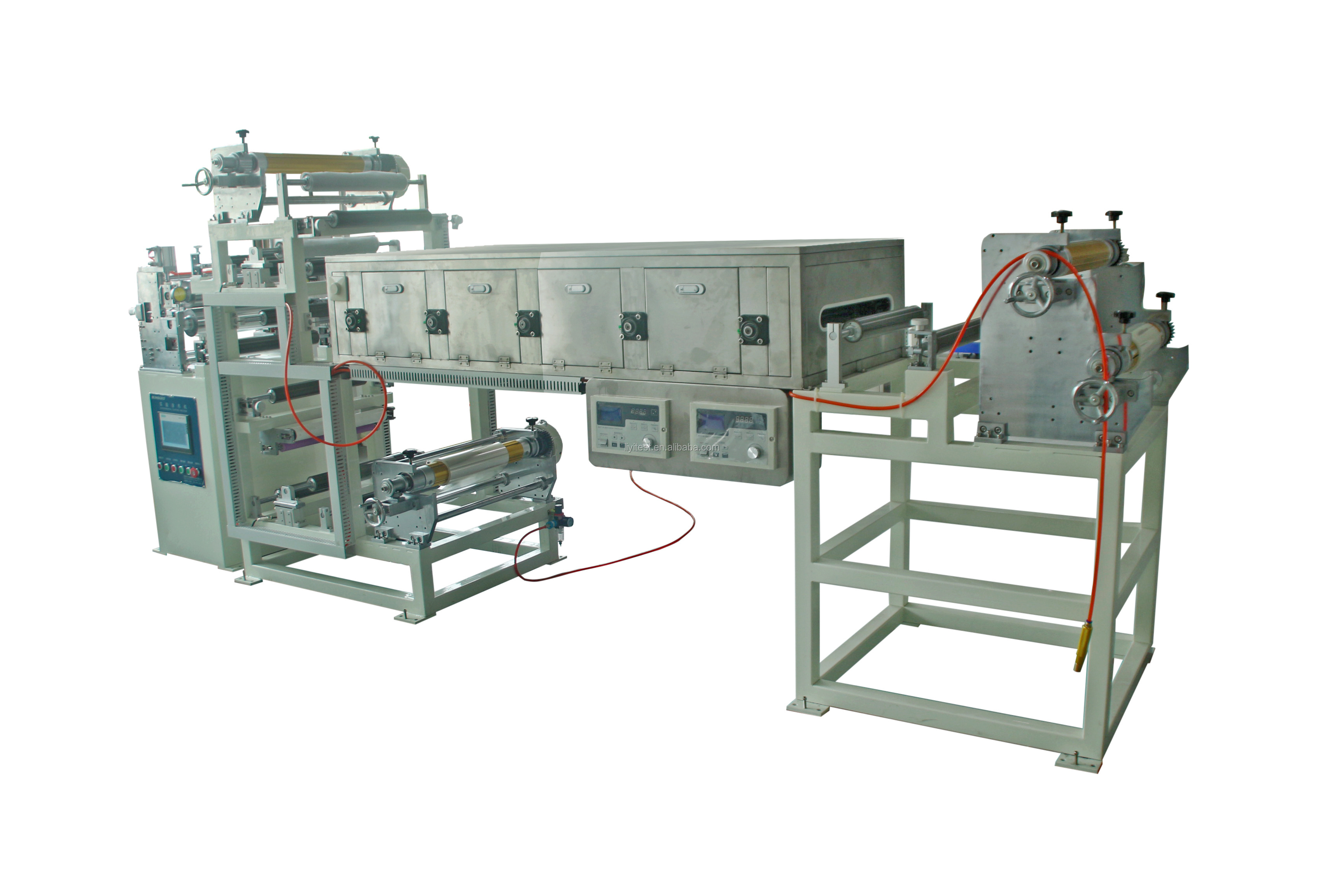

LIYI Lab Use PET PVC BOPP Hot Melt Fabric Laminating Self Adhesive Tape Paper Coating Machine

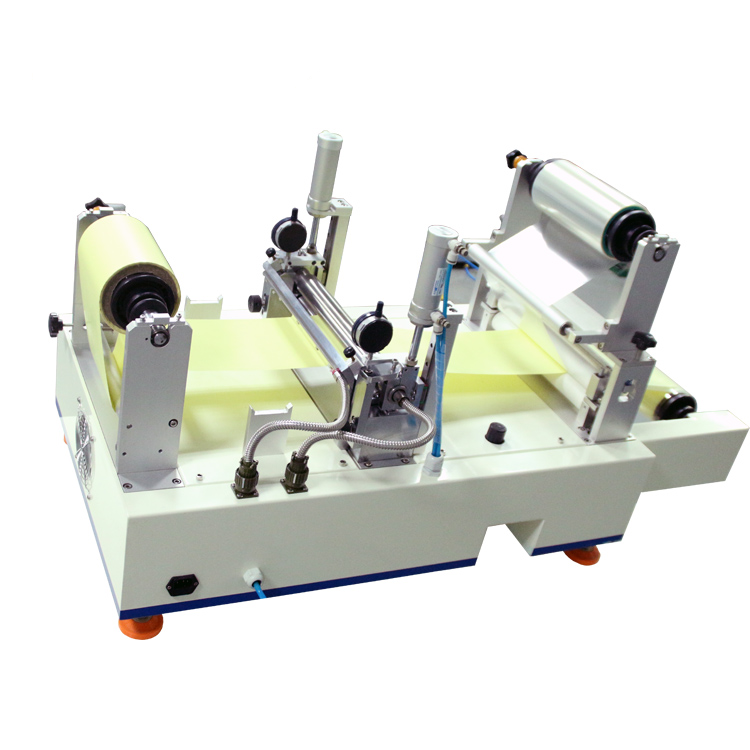

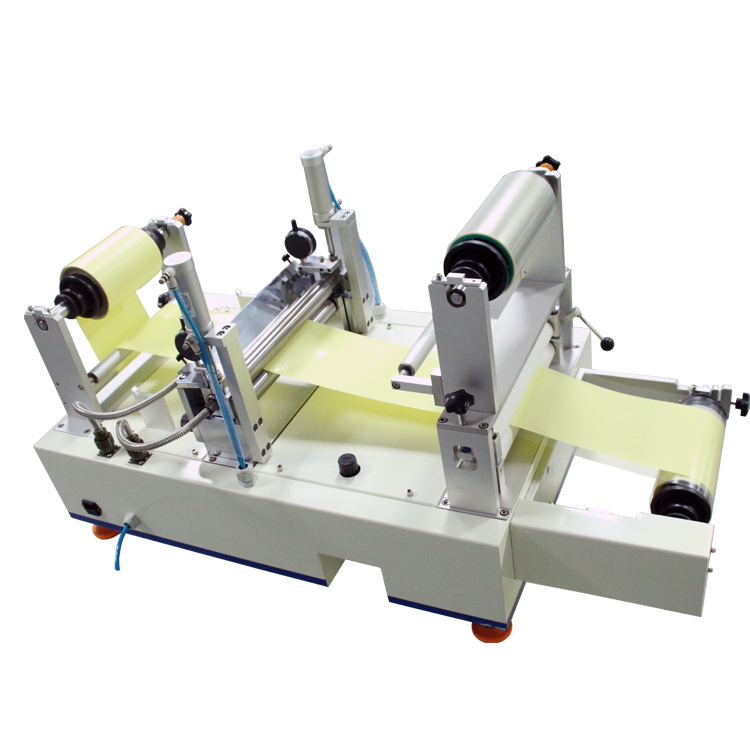

The Hot Melt Coater is capable of producing coated samples or small production of hot melt adhesives, and then laminating to a variety of foils, films, and papers. Lab scale simulations of production processes can be easily set up and studied.

Continuous coating proofing or small production of laboratory miniature hot melt adhesive coating and laminating machine. The hot-melt pressure sensitive adhesive can be directly coated on the heat-resistant substrate, or coated on the release paper and then applied to different surfaces, such as paper, plastic model metal film, etc. (50 μ m high temperature resistant PET film is recommended for the best experimental substrate).

Feature s :

1. The whole machine is assembled with high precision modular coating station structure.

2. High Precision PID temperature Control Mode of PT-100 on Rubber Wheel and Rubber Groove

3. Laminating speed and pressure are controllable

4. Clean up is easily accomplished through quick, uncomplicated disassembly

5. Generates sample laminates as long as needed

6. Precision ground coating bars

7. Both coating bars and the back reservoir are heated independently

8. Width of coating can be controlled by teflon insert side dams

9. Durable aluminum and steel construction means a long machine life with consistent performance

10. Variable speed controller can be adjusted

11. The coating clearance of the upper and lower rubber wheel is precisely fine-tuned to control the coating thickness. After the thickness setting, can lock the rubber wheel indirectly, prevents the clearance change.

12. The width of the coating is adjusted with two pieces of Teflon baffle in the rubber groove. Can be coated with unlimited length glue, automatic winding.

13.The coated liner bar can be adjusted to control the roll tension

14.The heating bar, the rubber roller and reservoir can be quickly disassembled separated from the host, it is perfect to clean adhesive residue.

|

Maximum operating temperature |

200 ℃ |

|

The maximum coating width |

2 0 0mm |

|

the maximum width of the sheet |

260mm |

|

the maximum width of coating |

160 mm |

|

The coating length |

unlimited |

|

Coating speed |

adjustable, max coating speed: 4.5m/min, the most suitable speed is 1-2m/min, |

|

Max capacity |

150g |

|

Minimum coating thickness |

0.05mm |

|

The maximum gap of total coating |

500 μ m(base material thickness) |

|

the optimum coating thickness |

≥ 20 μ m |

|

coating accuracy |

±5 μ m |

|

Dimension |

150 × 518(Containing motor 720) × 658 mm(L*W*H) |

|

Weight |

about 120kg |

|

Power source |

1 phase, AC 220V ,50HZ |

|

Rate of power |

1050W |