- Product Details

- {{item.text}}

Quick Details

-

Dimension:

-

Please contact us

Quick Details

-

Place of Origin:

-

Japan

-

Brand Name:

-

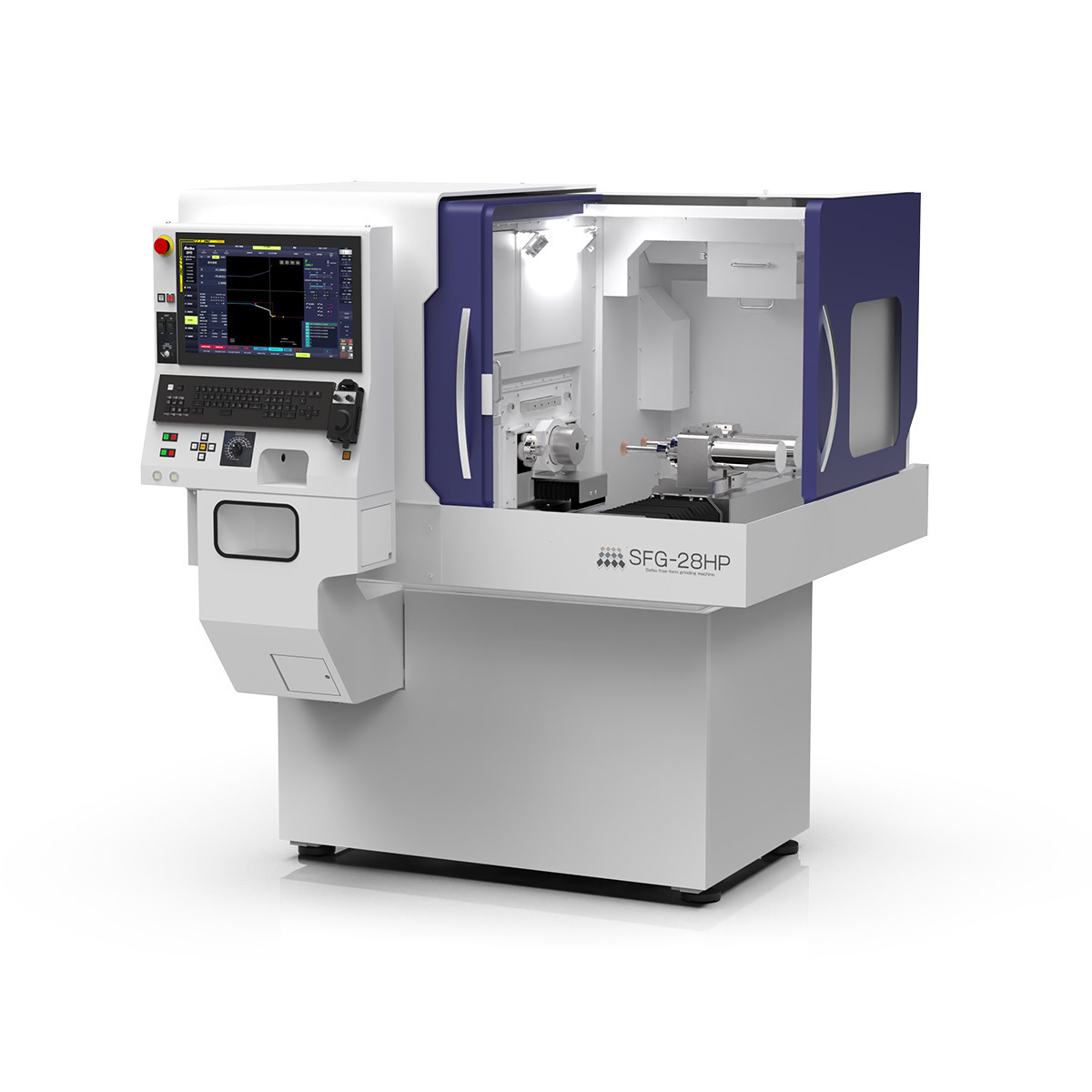

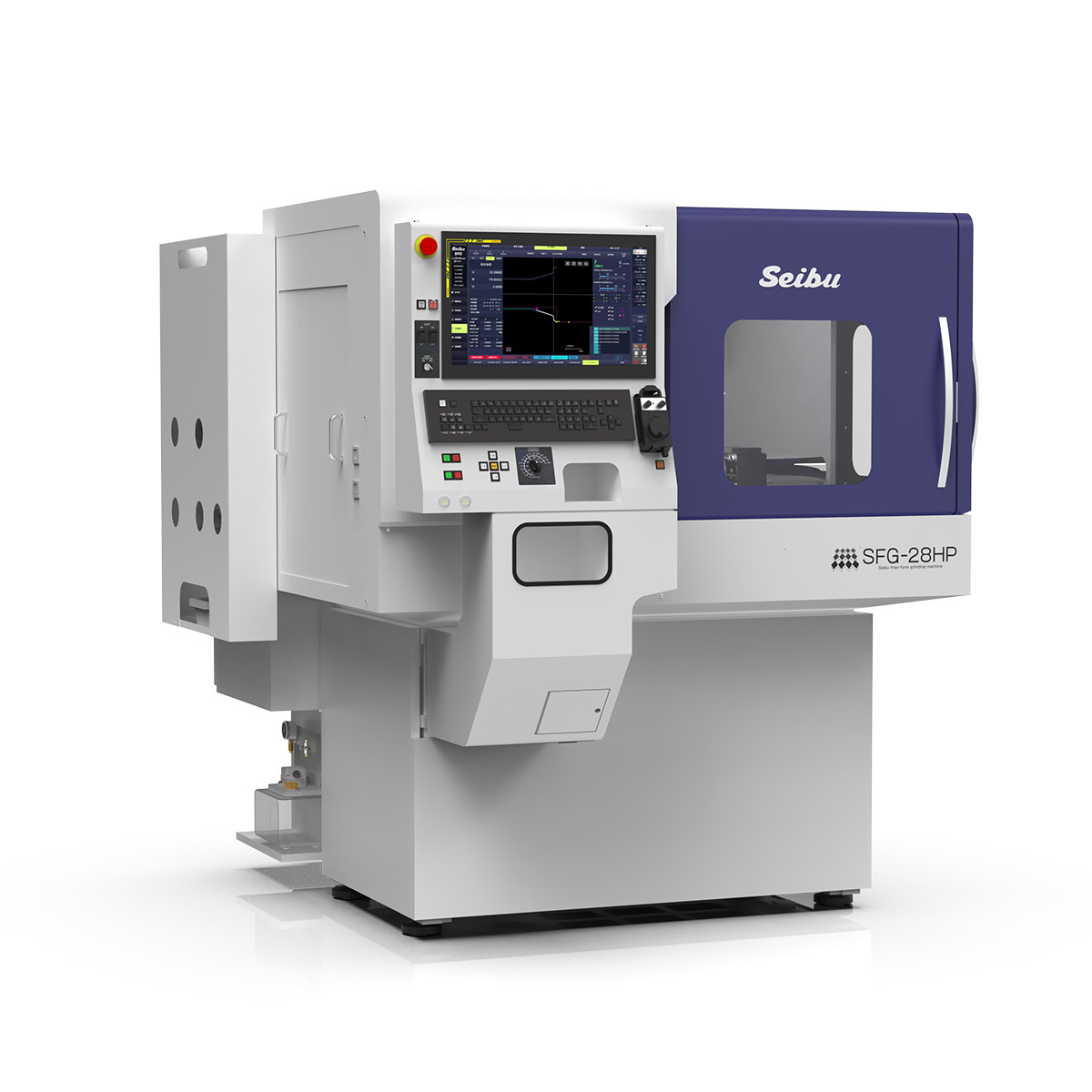

Seibu

-

Weight (KG):

-

2000

-

Dimension:

-

Please contact us

Products Description

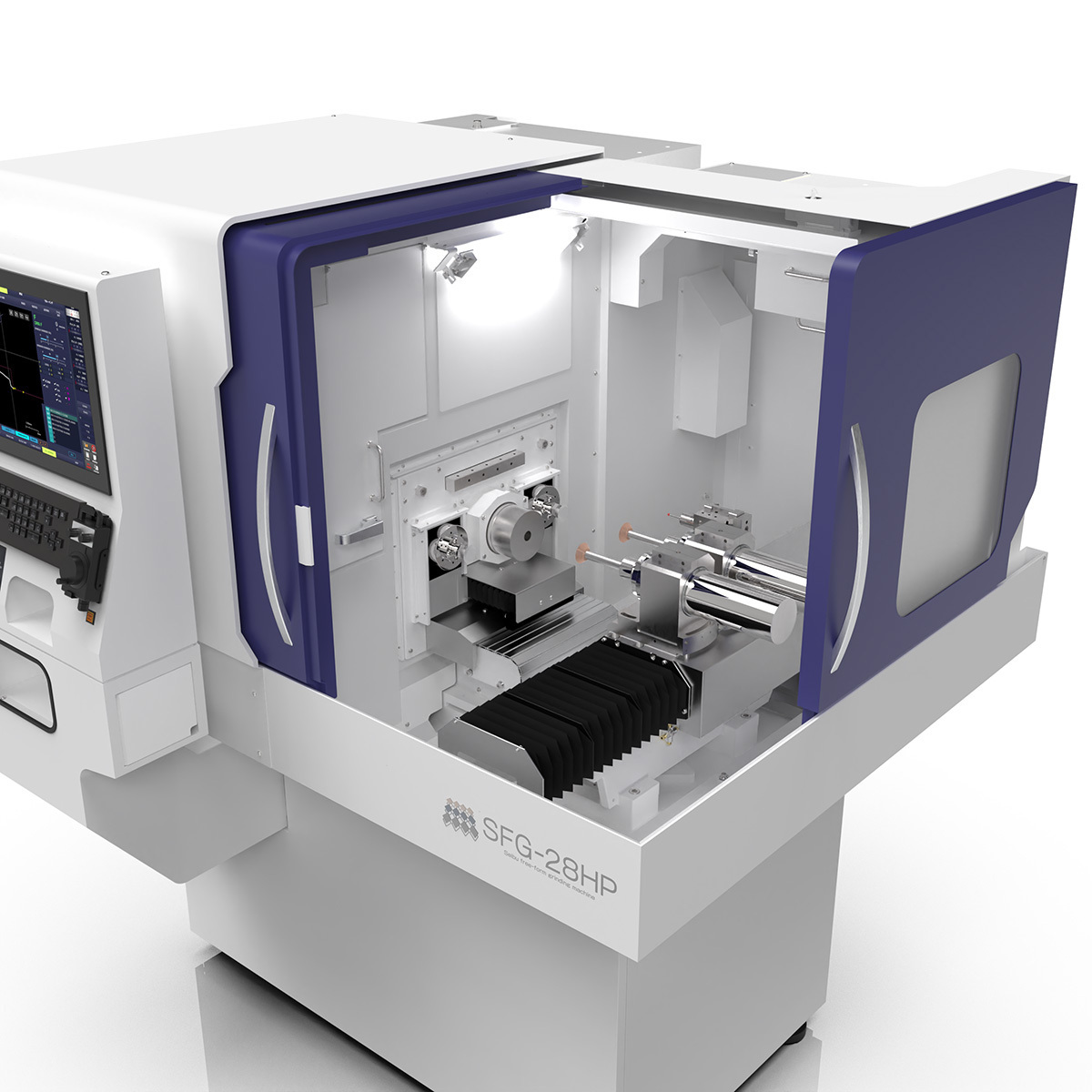

SNC-28TG, based on the SNC-20G, is an NC grinding machine equipped with 2 grindstone spindles of vertical/diagonal and horizontal.

In grinding of metal mold for optical lenses, it is possible to choose either “vertical-horizontal” or “diagonal- horizontal”.

Any two of the three patterns (vertical, diagonal, horizontal) can be selected, and it can handle a wide range of variations by just changing the grindstone spindle.

In grinding of metal mold for optical lenses, it is possible to choose either “vertical-horizontal” or “diagonal- horizontal”.

Any two of the three patterns (vertical, diagonal, horizontal) can be selected, and it can handle a wide range of variations by just changing the grindstone spindle.

As a result, retooling time has been cut to 50% or less of conventional systems.

SFG-28 has accomplished the roundness and flatness of 0.1μm.

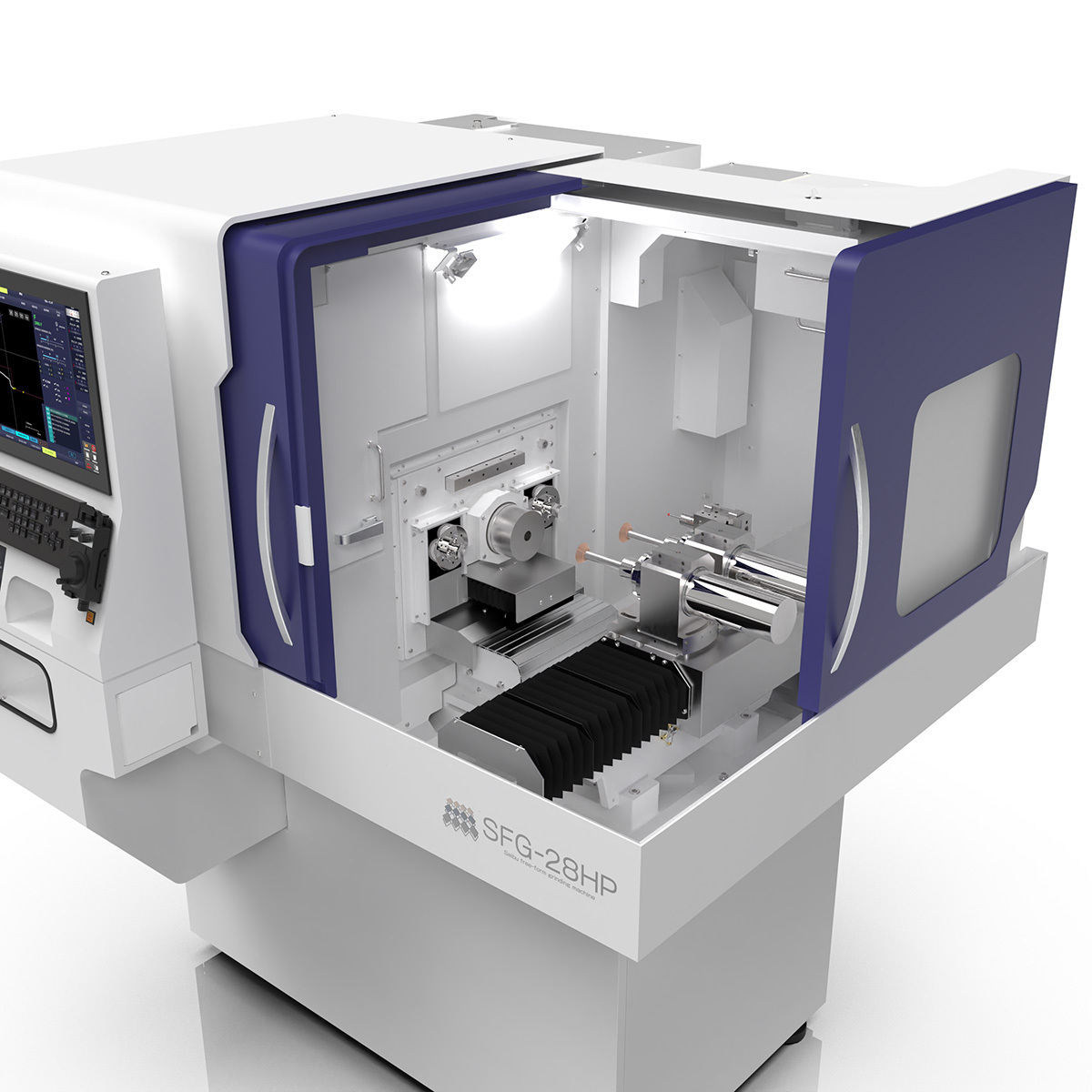

It is equipped with 2 grindstone spindles of 30,000 min-1. 80,000 min-1 and 2 truing units as standard.

SFG-28 system enables a succession of freeform grinding of radius, taper, and straight shape of inside/outside diameter highly accurately using the grindstone.

SFG-28 system enables a succession of freeform grinding of radius, taper, and straight shape of inside/outside diameter highly accurately using the grindstone.

Grinding shape or dimension can be automatically measured by the measuring equipment and automatically compensated without unloading the workpiece from chuck.

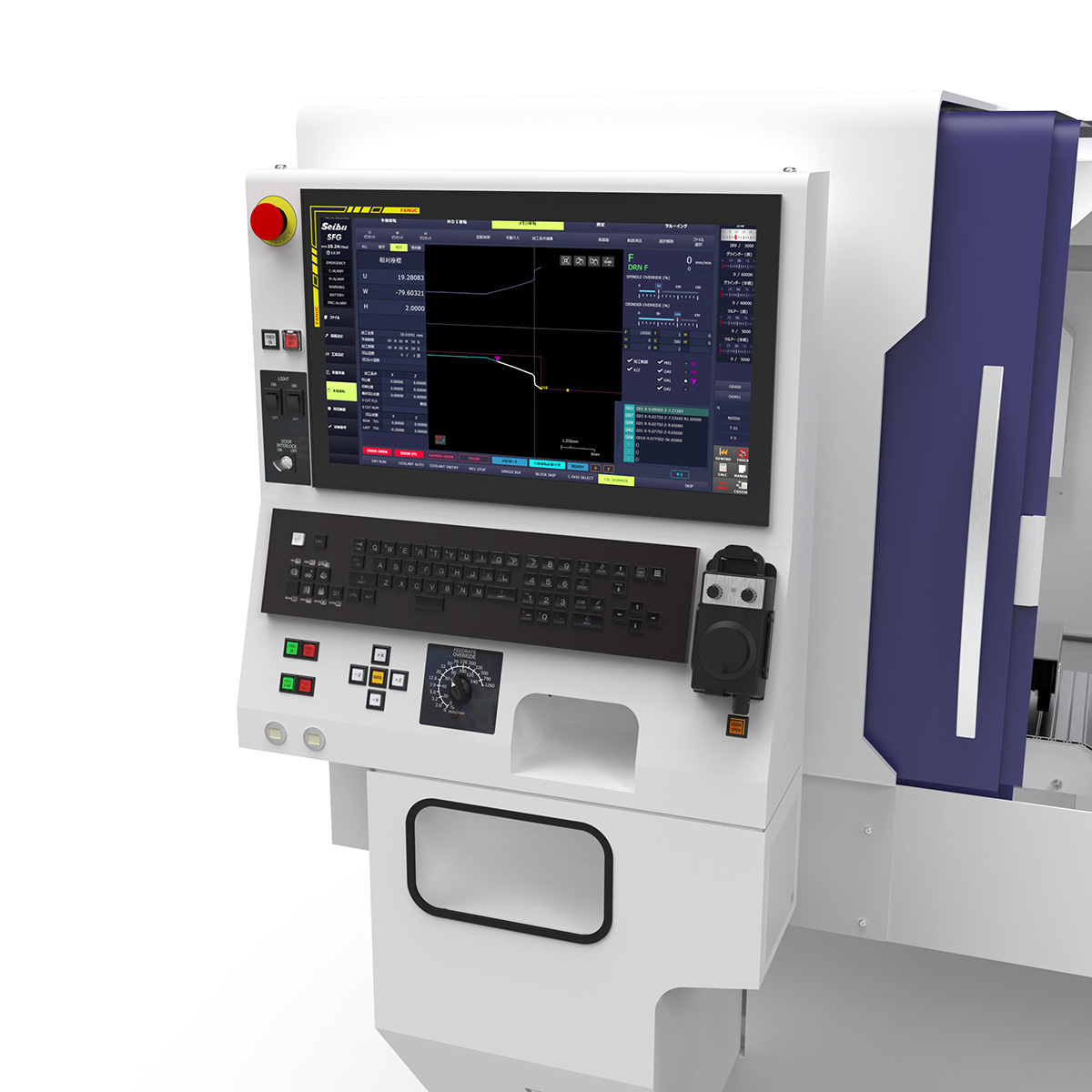

The least command increment of X,Z axes is 0.01μm (full closed control).

High-precision ceramic bearings assure high rigidity and high rpm precision for both work spindle and grindstone spindles.

Temperature regulator is provided as standard, and special thermal control for slide, spindle or each necessary part has been employed, which ensures thermal stability.

Temperature regulator is provided as standard, and special thermal control for slide, spindle or each necessary part has been employed, which ensures thermal stability.

|

|

P

|

HP

|

UP

|

|

Spindle speed

|

100~10,000min-1

|

100~3,000min-1

|

100~3,000min-1

|

|

Main spindle

thruhole diameter

|

φ20mm

|

φ20mm

|

φ20mm

|

|

Main motor

|

1.5kw/2.2kw

(Continuous/15min. rating)

|

1.5kw/2.2kw

(Continuous/15min. rating)

|

1.5kw/2.2kw

(Continuous/15min. rating)

|

|

X.Z-axis travel max

|

300mmx220mm

|

300mmx220mm

|

300mmx220mm

|

|

Repaid traverse

(X.Z-axis)

|

4m/min

|

4m/min

|

4m/min

|

|

Least command increment

|

0.1μm

|

0.01μm

|

0.01μm

|

|

Standard chuck

|

4"

|

4"

(High-performance chuck)

|

4"

(High-performance chuck)

|

|

Standard work size

|

φ50mmx50mm

|

φ50mmx50mm

|

φ50mmx50mm

|

|

Grinding spindle

|

2spindle

|

2spindle

|

2spindle

|

|

Grinding spindle

max. speed

|

60,000min-1(1.2kw)

|

60,000min-1(1.2kw)

|

80,000min-1(1.2kw)

|

|

Grinding spindle

slow rotation speed

|

25,000min-1(2.0kw)

|

25,000min-1(2.0kw)

|

30,000min-1(4.5kw)

|

|

Tooling system

|

―

|

2spindle (option)

|

2spindle (Standard)

|

|

Application

|

Automobile parts,

precision metal molds, etc.

|

Automobile parts,

precision metal molds, etc.

|

Automobile parts,

precision metal molds, etc.

|

|

NC device

|

FANUC 0i-T

|

FANUC 32i

|

FANUC 32i

|

Hot Searches