Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

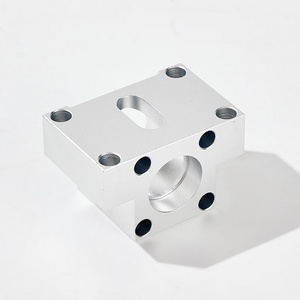

Model Number:

-

AL1963

-

Brand Name:

-

VMT

-

Product name:

-

cnc machining parts

-

Material:

-

Aluminum/Stainless Steel/Brass/Copper

-

Process:

-

CNC Machining Parts CNC Turning/CNC Milling,etc

-

Roughness:

-

Ra0.2-Ra3.2(Custom Available)

-

Tolerance:

-

0.01- +/-0.005mm

-

Service:

-

One-Stop Service/OEM/ODM cnc machining parts service

-

Surface treatment:

-

anodizing, powder coating, Sandblasting

-

Equipment:

-

CNC Machining Center,CNC Lathe

-

Certification:

-

ISO9001:2015,RoHS

-

Color:

-

Black/Blue/Dark Grey/Orange/Red,etc

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, custom machining

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

AL1963

-

Brand Name:

-

VMT

-

Product name:

-

cnc machining parts

-

Material:

-

Aluminum/Stainless Steel/Brass/Copper

-

Process:

-

CNC Machining Parts CNC Turning/CNC Milling,etc

-

Roughness:

-

Ra0.2-Ra3.2(Custom Available)

-

Tolerance:

-

0.01- +/-0.005mm

-

Service:

-

One-Stop Service/OEM/ODM cnc machining parts service

-

Surface treatment:

-

anodizing, powder coating, Sandblasting

-

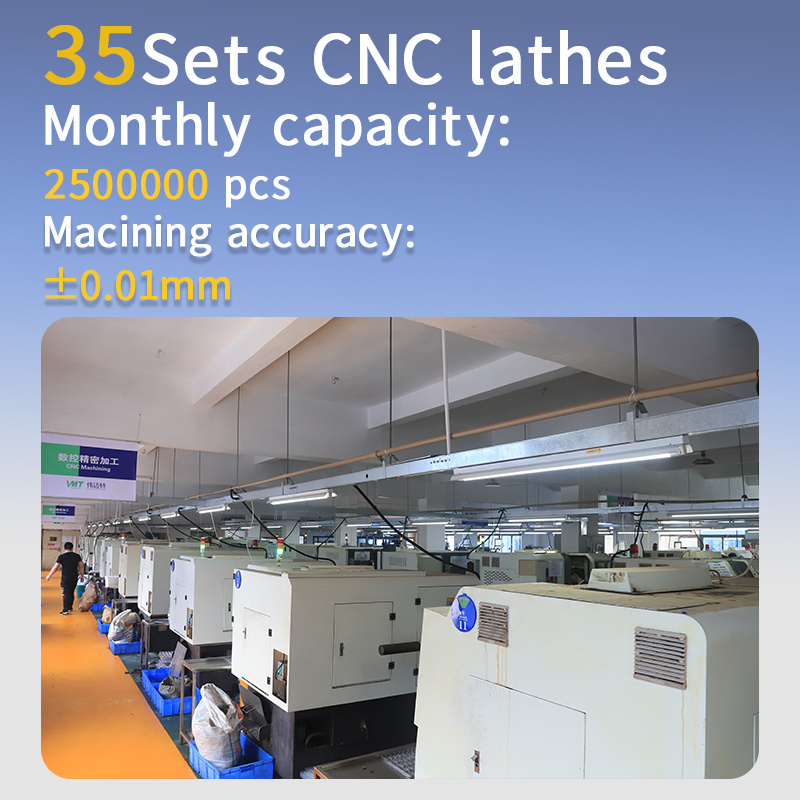

Equipment:

-

CNC Machining Center,CNC Lathe

-

Certification:

-

ISO9001:2015,RoHS

-

Color:

-

Black/Blue/Dark Grey/Orange/Red,etc

Citizen swiss-type

5 axis cnc machining

Automatic lathe

CNC lathe

Do you know the advantages and disadvantages of different lathe?

Choosing the right machine according to different materials and structures is the key to reducing costs and improving

accuracy and quality.

|

Lathe type

|

Advantages and disadvantages

|

Suitable material

|

Some applicable industries

|

|

Automatic lathe

|

only manufacturing turning parts within the outer diameter 20MM or less. One person can operate multiple machines, the lowest cost

machine in cnc turning services.

|

Aluminum, Copper, Iron, SUS303, POM

|

Copper nuts, rivets. Connector parts

|

|

CNC lathe

|

Split cutter lathe and turret lathe. Split cutter lathe is suitable for parts vr th an outer diameter of 45MM cr less, a length of less than 100MM. and simpler parts. It is characterized by high efficiency. The turret lathe is suitable for thin and long parts.

|

Aluminum, copper, stainless steel, iron, titanium alloy, POM

|

Flashlight housing, shaft, electronic cigarette parts

|

|

Turn-mill combination

|

The precision turning parts can be processed at one time, and the geometric tolerance is high, but because the fourth axis speed s

tow. the tumiig tme ts slow. |

Aluminum, copper, stainless steel, iron, titanium alloy. POM

|

Precision connector parts

|

|

Citizen swiss Automatic Lathe

|

Tum slender parts and the fourth axis can be processed at one tine.

|

Aluminum, Copper, Iron, SUS303, POM

|

Prater shaft, Connecter parts

|

VMT provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and postprocessing services for your diverse manufacturing requirements.

|

CNC Machining Standards

|

|

|

||

|

Type

|

Tolerance

|

|

||

|

Linear dimension

|

+/- 0.025 mm

|

+/-0.001 inch

|

||

|

Hole diameters(not reamed)

|

+/- 0.025 mm

|

+/- 0.001 inch

|

||

|

Shaft diameters

|

+/- 0.025 mm

|

+/- 0.001 inch

|

||

|

Smallest thread size available

|

M1x0,25

|

|

||

|

Part size limit

|

950 * 550 * 480 mm

|

37.0 * 21.5 * 18.5 inch

|

||

|

If no 2D drawing is provided, RapidDirect produces parts according to ISO 2768 M standard. With 2D drawing, we can reach tolerance as tight as +/- 0.01 mm.

|

|

|

||

Ensure that we provide you with the best quality and most beautiful parts

Technical assessment and

Material verification

Before the start of the production phase, our

engineering team will conduct technical

assessmentand material verification according to customer requirements.

In-process quality control

During the machining process, quality control personnel conduct routine inspections on all parts being produced every two hours to avoid problems and save costs and time.

Before delivery inspection

Carry out a full-scale inspection report before shipment: number of parts, key dimensions, threads and tolerances, thickness and depth, appearance of parts, etc.

Packaging

Four layers of protection:

1. Wrapping paper

2. Pearl cotton

3. Foam

4. Use paper/wooden boxes during packaging

FAQ

Q1:What's kinds of information you need for quotation?

VMT: You can provide 2D/3D drawing or send your sample to our factory, then we can make according to your sample.

Q2: Can we sign NDA?

VMT: Sure. We never divulge customers' information to anyone else.

Q3: Do you provide sample?

VMT: Yes, we can provide you sample before mass order.

Q4: How can you ensure the quality?

VMT: We have profesional QC department to guarantee the quality.

Q5: Delivery time

VMT: If in Stock: around 3 days after payment. Mass production: around 20~25 days after receipt of deposit (Accurate delivery time depends on specific items and quantities).

Hot Searches