- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

eversun

-

Product Name:

-

Big Bag Discharge Station machine

-

Application:

-

Industrial Filed

-

Type:

-

Atuomatic

-

Usage:

-

Conveying Products

-

Key Words:

-

dust free bulk bag unloading stations

-

Capacity:

-

Customized

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Color:

-

Customized Color

-

Load capacity:

-

1t - 300t

-

Function:

-

Conveying Goods

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

100

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

eversun

-

Product Name:

-

Big Bag Discharge Station machine

-

Application:

-

Industrial Filed

-

Type:

-

Atuomatic

-

Usage:

-

Conveying Products

-

Key Words:

-

dust free bulk bag unloading stations

-

Capacity:

-

Customized

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Color:

-

Customized Color

-

Load capacity:

-

1t - 300t

-

Function:

-

Conveying Goods

Product Description

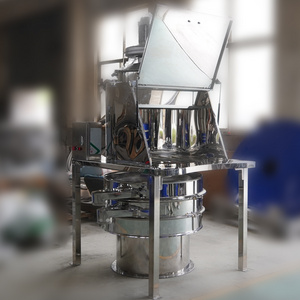

Bulk bag unloader

Bulk bag unloader is used to unpack and unload tons of powdery and granular materials. The equipment is equipped with a rack, a lifting device, and a ton bag unloading and feeding station, which is used for the folding and unloading of ton bags of powdery and granular materials. The equipment is composed of a frame, a lifting device, a diaphragm, a temporary storage bin, etc. according to the process characteristics and equipment size, two different ways can be adopted: a flat machine and a forklift; It can be equipped with double rails for the installation of two electric hoists to improve the bag removal efficiency; Materials are divided into carbon steel and stainless steel; The whole set of equipment has good sealing and easy operation, which greatly improves the production environment and production efficiency.

1. using forklift, crane or electric hoist as lifting equipment can reduce the labor intensity

2. it can be equipped with crushing, flapping, vibrating and magnetic separators, which can effectively crush block materials; Tapping can completely discharge the materials in the ton bag without residue

3. the bag clamping device adopts pneumatic or physical mode, especially the double channel bag clamping mode, so that the materials do not leak, do not layer, and do not generate dust

4. the outlet of the ton package feeding station can be connected to: rotary discharge valve, hopper, silo, manual feeding station, vacuum feeder, mixing tank, etc

Certifications

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches