- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Gianttools

-

Model Number:

-

G-12

-

Product name:

-

steel file

-

Color:

-

Customer Color Acceped

-

Usage:

-

Muliti-purpose

-

Cut Type:

-

Half Round

-

Size:

-

4"/5"/6"/7"/8"/9"/10"/12"/14"/16"

-

Material:

-

T12 High Carbon Steel

-

OEM:

-

Accpted

-

Design:

-

OEM Acceptable

-

Feature:

-

Eco-Friendly

-

Logo:

-

Customized Logo

Quick Details

-

Style:

-

American Pattern File, Swiss Pattern File, Other

-

Shape:

-

Round, Square, Flat, triangle, Taper, Half Round

-

Type:

-

Rotary Files, Saw Files, NEEDLE FILES, Warding Files, Rectangle Files, Half Round Files, Round Files, Square Files, Triangle Files, Thread Repair Files, File Handles

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Gianttools

-

Model Number:

-

G-12

-

Product name:

-

steel file

-

Color:

-

Customer Color Acceped

-

Usage:

-

Muliti-purpose

-

Cut Type:

-

Half Round

-

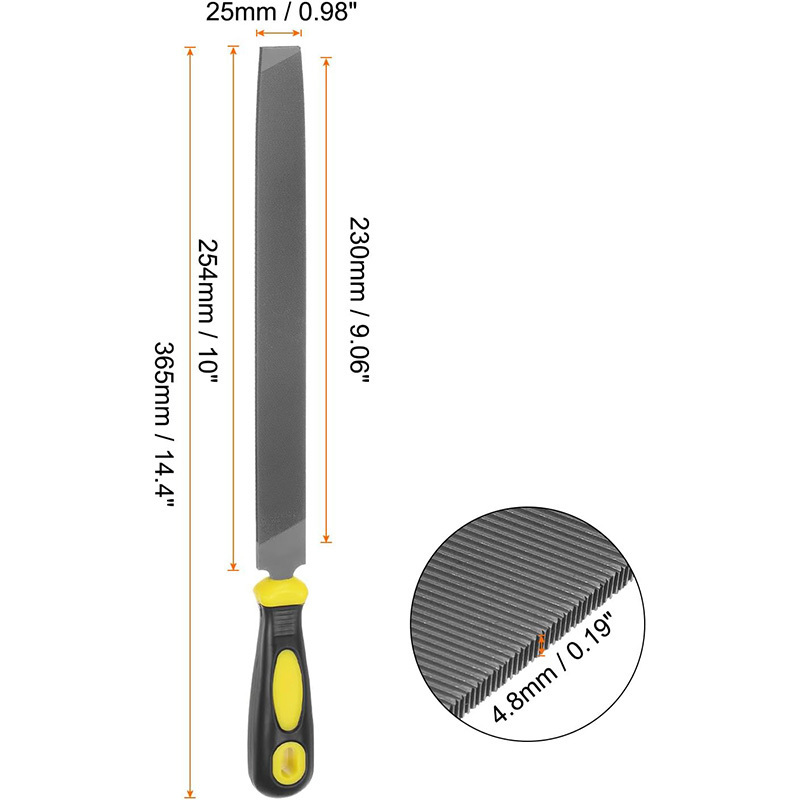

Size:

-

4"/5"/6"/7"/8"/9"/10"/12"/14"/16"

-

Material:

-

T12 High Carbon Steel

-

OEM:

-

Accpted

-

Design:

-

OEM Acceptable

-

Feature:

-

Eco-Friendly

-

Logo:

-

Customized Logo

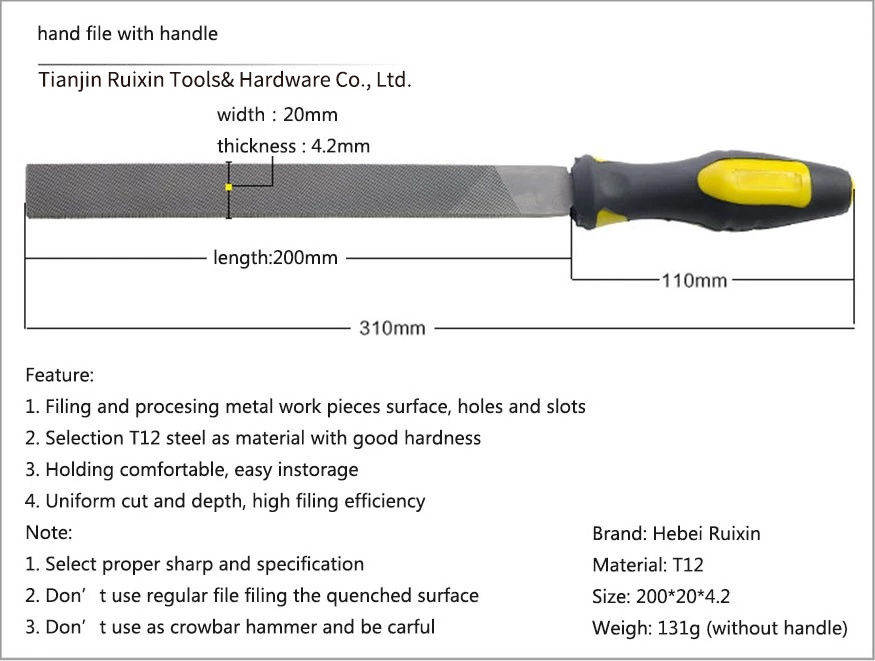

Products Description

|

Model

|

Specification(mm)

|

size

|

Weight(g)

|

Hardness

|

|

Flat file

|

16*150

|

6"

|

126

|

63HRC

|

|

Half Round File

|

16*150

|

6"

|

197

|

63HRC

|

|

Round File

|

4.5*150

|

6"

|

88

|

63HRC

|

|

Triangular File

|

8.2*150

|

6"

|

112

|

63HRC

|

|

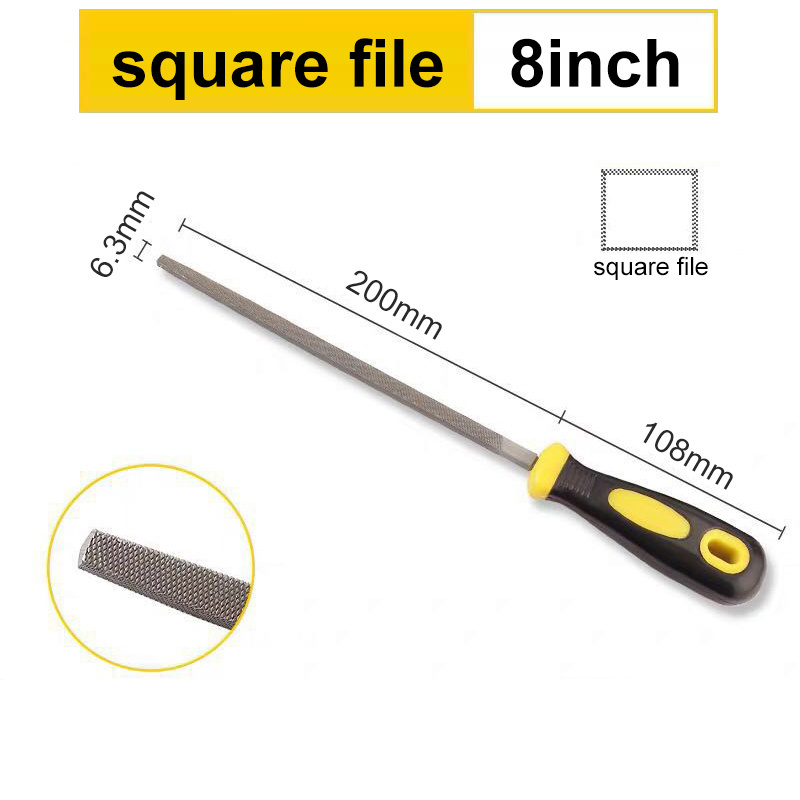

Square File

|

4.6*150

|

6"

|

98

|

63HRC

|

Product Details

Our Advantages

Usage suggestions

Always operate the burr within the recommended speeds guide.

Always ensure the appropriate tool is used and that tis regularly maintained.

Alwaysfix the maximum length of burr in the collet.Do not exceed the recommended maximum over hang. Long shank burrs require slower running speeds.

Always use a smooth cutting action with constant movement in both directions.

Don't Run burr above the maximum operating speed,this can cause premature tooth wear.

Don' t run a burr too slowly, this can cause chipping.

Don't Sink the burr to more than one third of its periphery. Do not encapsulate.

Don't Allow burr to become too hot, this may cause the braze to soften and cause the head to become detached from the shank (only applies to burrs where head diameter is greater than the shank diameter).

Hot Searches