- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

2.5KW

-

Product name:

-

Canned mushroom Production Line

-

Type:

-

Fully Automatic

-

Function:

-

Multifunctional

-

Usage:

-

Food Industry Equipment

-

Capacity:

-

1~60 Tons

-

Feature:

-

High Efficiency Easy Operate

-

Keywords:

-

Mushroom Cleaning Washing Line

-

Processing Types:

-

Mushroom Process Equpiment

-

Application:

-

Food Processing Machine

Quick Details

-

Machinery Capacity:

-

OEM

-

Brand Name:

-

LWT

-

Year:

-

OEM

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

2.5KW

-

Product name:

-

Canned mushroom Production Line

-

Type:

-

Fully Automatic

-

Function:

-

Multifunctional

-

Usage:

-

Food Industry Equipment

-

Capacity:

-

1~60 Tons

-

Feature:

-

High Efficiency Easy Operate

-

Keywords:

-

Mushroom Cleaning Washing Line

-

Processing Types:

-

Mushroom Process Equpiment

-

Application:

-

Food Processing Machine

Canning

Processing Equipment

Mushroom Production Line

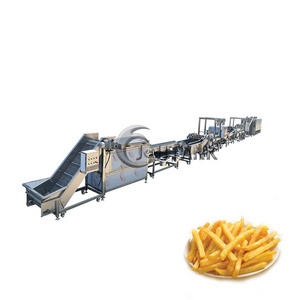

Product Description

Canned Mushroom Production Line

Shanghai LWT could offer you the best canned production line, we could analysis according to your application occasion , then design the whole process, and work out the best solution according to your requirement . we could offer our best post-service such as the technique training. And besides, you could enjoy a good business future for manufacturing the canned food for the customer in the market, for the canned food, we have the production line for the Meat, Fish, Vegetables, Fruits, Beans, Mushrooms, Canned Pets for the finished canned food.

Working process

Mushroom washing mahcine, pre-cooking-cooling, grading, slice, cart loading, seal, exhaust, filling, retort, cart unloading, dryer, filled canspalletizer, storage, packing production line

Parameters

|

Product Name

|

canned mushroom canning machine can mushroom product line

|

|

Application

|

mushroom and other canned food

|

|

Operation mode

|

Fully automatic / semi-automatic (customized)

|

|

Capacity

|

1400-6000bph(It can be customized according to the capacity)

|

|

Support bottle type

|

Glass Bottle,Iron Cans,Plastic Jar

|

|

Name

|

Funtion&Specifications

|

|

|

Mushroom pre-processing line

|

|

|

|

1. Mushroom washing machine

|

|

|

|

2. Pre-cooking-cooling

|

With cooling 5min (85℃-90℃) L=10m W=1100mm

|

|

|

3. Grading

|

Seperate different size

|

|

|

4.Slice

|

|

|

|

5. Filling

|

moving to tank of filling machine

|

|

|

6.Exhaust

|

let the air out

|

|

|

7. Seal

|

Sealing Can

|

|

|

8. Cart loading

|

|

|

|

9. Retort

|

sterilization

|

|

|

10.Cart unloading

|

|

|

|

11. Dryer

|

dry the surface of cans

|

|

|

12. filled cans palletizer

|

|

|

|

13. Storage

|

|

|

|

14. Packing production line

|

|

|

Other Parameters

1.Empty Cans De-palletizer

Empty cans de-palletizer is mainly composed of lifting mechanism, moving mechanism, magnetic suction mechanism, conveyor and

electrical controlling system. The working way adopts magnetic suction and moving type. It can match with magnetic lifting conveying system, can transport product in the air and can transport product among different height of floor.

electrical controlling system. The working way adopts magnetic suction and moving type. It can match with magnetic lifting conveying system, can transport product in the air and can transport product among different height of floor.

It can replace the manual ways arrangement and traditional empty can unloading machine, saving a lot of manpower and increasing production effects.

2.Magnetic washing machine and drying machine

The machine is mainly used for continuous washing for various kinds of tin cans( round can special shape of cans). Different shape and size of cans only need adjust the machine , no need change accessories. Adopt steam heating optional). temperature is adjustable; high pressure water sprayer; The cleaning effect is good , the structure is reasonable , and the production efficiency is high)

|

Name

|

Magnetic washing machine

|

LW-WM100

|

|

|

Capacity

|

50-300cans/min

|

50-100 cans/min

|

|

|

Washing Section

|

1-2 Section washing

|

1 Section washing

|

|

|

can diameter

|

40-150mm

|

40-150mm

|

|

|

Power

|

1.5KW

|

1.1KW

|

|

3.Auto Weight and Filling Machine

This machine is suitable for glass jar,iron cans,plastic jars,big mouth bottle and so on.Mainly used to Beans,Peach Flap,Peach

Strip,Hawthorn,Strawberries,Grapes,Apricots,Lychee,Braise in soy sauce meat. Mutton, pork, chicken,fish and so on,any kinds of solid products canning measuring and filling.

Strip,Hawthorn,Strawberries,Grapes,Apricots,Lychee,Braise in soy sauce meat. Mutton, pork, chicken,fish and so on,any kinds of solid products canning measuring and filling.

Model:

LW-FWS50

Capacity:

2400-3000bph

Measuring range:

50g-2000g

Measurement accuracy:

±

2-10g

|

Moldel

|

Capacity

|

Filling volume

|

|

LW-FPP-4A

|

480bph-720bph

|

10-60g

30-100g 50-250g 100-500g 200-1000g 500-2500g 1000-5000g |

|

LW-FPP-6A

|

960bph-1920bph

|

|

|

LW-FPP-8A

|

1440bph-2880bph

|

|

|

LW-FPP-10A

|

1920bph-3840bph

|

|

|

LW-FPP-12A

|

2400bph-4800bph

|

|

5.

Can sealing machine

Automatic vacuum sealing equipment, it is specially used for tinplate, aluminum round cans and various different sealing types.

The machine can vacuumize and add nitrogen thus to keep the product long time.

6.Sterilization Machine Retort

It is mainly applied to all kinds of cans of drinks, tin cans of drink, canned meat, canned vegetables and secondary sterilization plastic bottle beverage etc process loading automatically before sterilization,unloading after sterilization,replace the artificial working,save manpower, greatly improve production efficiency.The machine adopts magnetic suction to prevent the chafing and squeezing of the cans.

7.Filled Cans Washing and Drying Machine

It is applied to clean and dry outside surface of all kinds of canned fruit,canned meat,bottled sauce and all kinds of drinks.(specialize in washing and drying the adhensive sugar water and otheradhenionoutside of the sealed canned products or beverage),applying for tin cans,glass bottles and plastic bottles.

8.Wet Glue Labeling Machine

It Adopts enclosed transmission box,full mechanical

transmission,

adhesive attached to various round bottle labels,stable and reliable.suitable for round pot labeling.

9.Filled Cans Palletizer/De-palletizer

Filled Cans Palletizer is suitable for palletizer and depalletizer of the filled glass bottles,filled tin cans,empty tin cans,it is main composed of conveying system and palletizing system.Working way uses magnetic grabmovement.

10.Carton Erector

The automatic boxopening machine is used to open the carton board, and the bottom of the box is folded according to a certain procedure, then sealed with tape to be delivered to the special equipment of the boxing machine.

Hot Searches