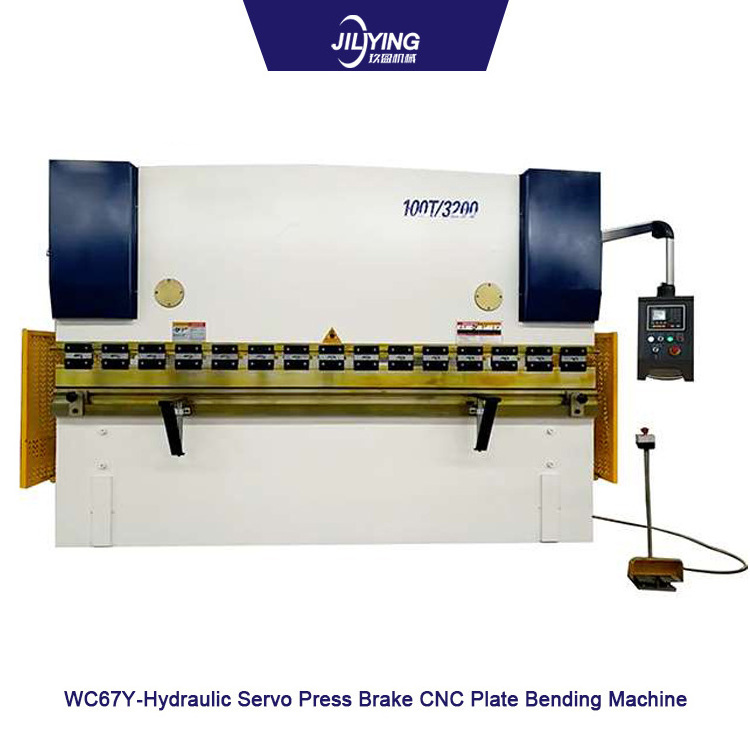

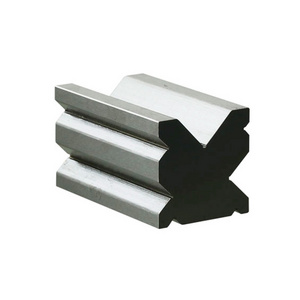

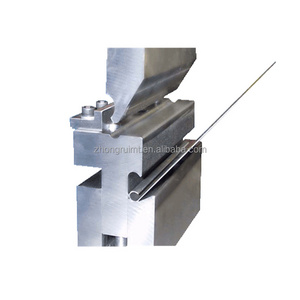

hydraulic press brake cnc bending machine with precision backgauge, servo motor,safety protection, fast clamp, ball screw and linear guide. All from Germany, USA, Holland, Italy Brand parts.

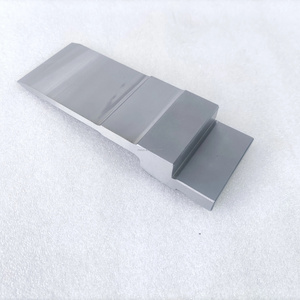

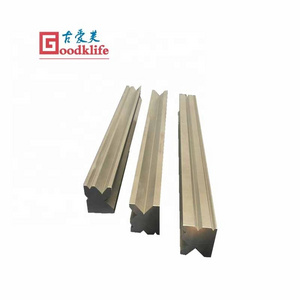

The bend thickness and length can be manufactured customized.

The bend thickness and length can be manufactured customized.