- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Packaging Type:

-

Packaging type can be customized according to the filled product.

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Z.X Smart

-

Dimension(L*W*H):

-

1500mm*651mm*1084mm

-

Weight:

-

200 KG

-

Product name:

-

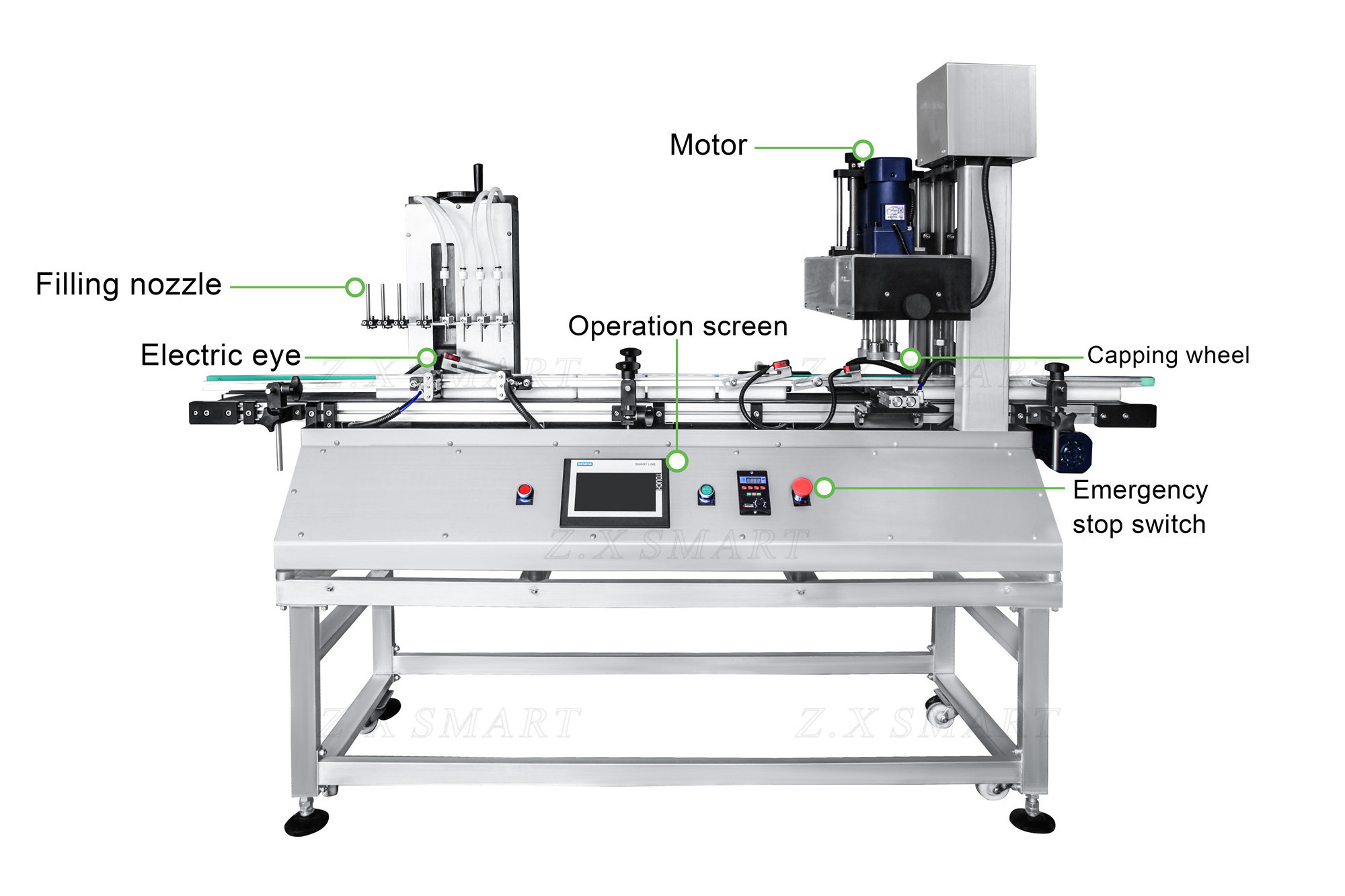

Automatic Table Top Bottle Liquid Filling Production Line

-

Filling head:

-

4, can be customized

-

Filling speed:

-

20-30 bottles/min(50-500ml)

-

Capping speed:

-

20-35 bottles/min

-

After-sales Service:

-

7/24 Video service, online service, spare parts

-

Bottle type:

-

The bottle provided by the customer

-

Advantage:

-

20 Years Experiences, factory price

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304/316

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Machinery Capacity:

-

500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Packaging type can be customized

-

Filling Material:

-

Liquid, Cosmetic prosucts

-

Filling Accuracy:

-

±1%

-

Packaging Type:

-

Packaging type can be customized according to the filled product.

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Z.X Smart

-

Dimension(L*W*H):

-

1500mm*651mm*1084mm

-

Weight:

-

200 KG

-

Product name:

-

Automatic Table Top Bottle Liquid Filling Production Line

-

Filling head:

-

4, can be customized

-

Filling speed:

-

20-30 bottles/min(50-500ml)

-

Capping speed:

-

20-35 bottles/min

-

After-sales Service:

-

7/24 Video service, online service, spare parts

-

Bottle type:

-

The bottle provided by the customer

-

Advantage:

-

20 Years Experiences, factory price

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304/316

-

Marketing Type:

-

Hot Product 2021

Product Description

Automatic Table Top Perfume Cosmetic Liquid Filling Production Line

Description:

The whole machine is a linear mechanism, which is driven by magnetic pump and servo motor to achieve high-precision filling dosage. It is easy to operate and can change the bottle type quickly. The biggest feature of this machine is that it covers a small area, is affordable, and is easy to disassemble and clean.

It is used for automatic fillling and capping for bottles in cosmetic, daily chemical, medicine industry, water, beverage. It can be applied to a variety of bottle types with high production efficiency.

Wide Range of Applictions

|

Technical Parameter

|

|

|

|

Number of filling heads

|

4

|

|

|

Filling volume

|

10-1000ml

|

|

|

Filling form

|

Magnetic pump multi-head filling

|

|

|

Cap feeding way

|

Feed caps manually or automatically

|

|

|

Capping way

|

Clamp screw

|

|

|

Filling accuracy

|

±1%

|

|

|

Working speed

|

20-35 bottles/minute

|

|

|

Program control

|

PLC+Touch screen

|

|

|

Power

|

About 2KW/220V/50Hz, single phase

|

|

|

The machine material in contact with liquid

|

316 stainless steel, PTEF

|

|

|

The filling frame is made of stainless steel

|

|

|

|

|

||

Details Images

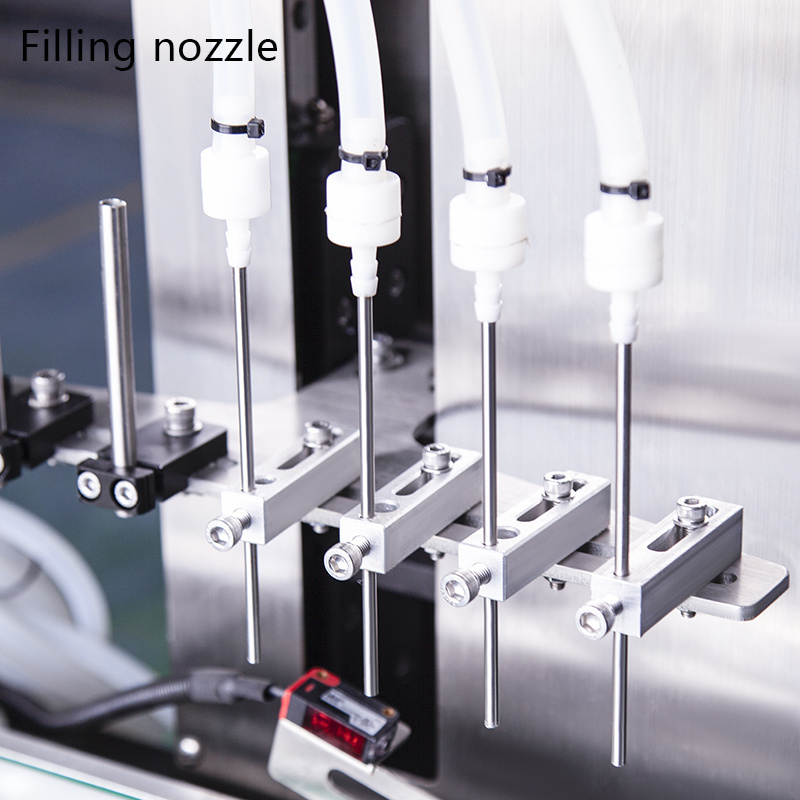

Filling Head

Equipped with 4 magnetic pump filling heads, the filling speed is fast while preventing foaming and splashing of liquids. The filling heads can be increased or reduced according to requirements.

Capping Wheel

The middle wheel presses the bottle cap, while the four wheels next to it clamp the bottle cap for rotation. The tightness of the rotation is adjusted according to your bottle caps and

it won't damage

the bottle cap and sufficiently tight.

Touch Screen

Equipped with imported

Siemens

touch screen, intelligent control of the entire machine, responsive and error free. Any parameters related to the machine can be adjusted and have memory function.

Electric Sensor

Adopting imported

Leuze sensor

.

Although small in size, it has multiple functions, real-time monitoring of bottle filling, improving production efficiency and quality, and reducing operating costs.

Capping Part Motor

The motor rotates internally and drives the four capping wheels to tighten the bottle cap. The two motors work together, resulting in higher production efficiency. And the motor can be operated and stopped on the touch screen.

Related Products

Hot Searches