- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

400

-

Voltage:

-

380 V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhong Xin

-

Dimension(L*W*H):

-

2950*1260*2150 MM

-

Product name:

-

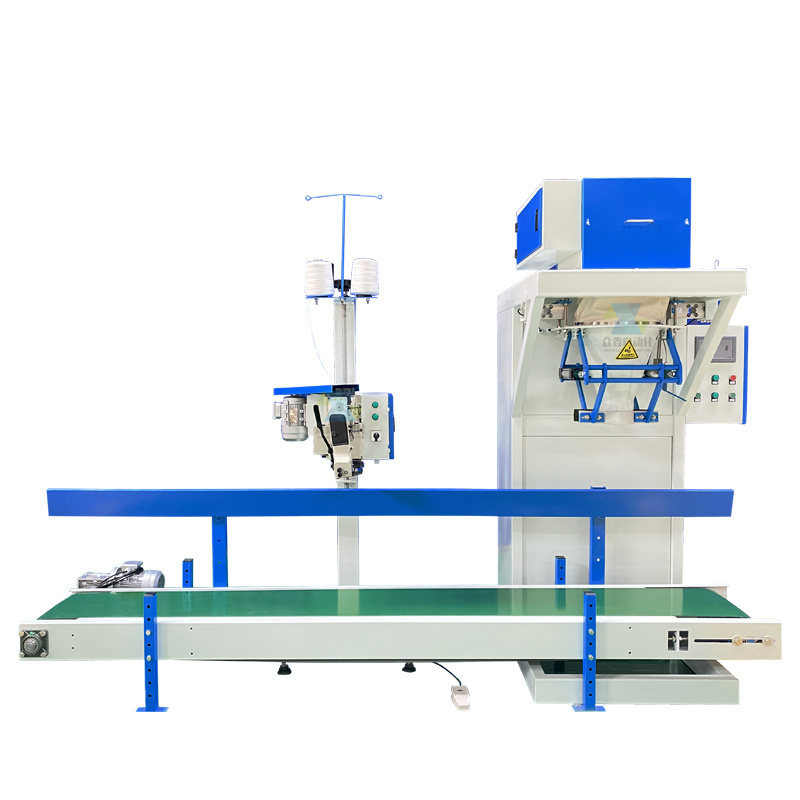

Powder bagging machine

-

Special:

-

Customization

-

Keyword:

-

Bagging machine

-

Color:

-

Customers' requirement

-

Advantage:

-

Easy operation

-

Speed:

-

180-300bags/hour or 360-480bag

-

Material:

-

Stainless steel

-

Suitable for:

-

Rice flour /corn starch/feed/wheaten starch

-

Pouch type:

-

Sack

-

Quality:

-

High quality

Quick Details

-

Function:

-

FILLING, Wrapping, Capping, COATING, Sealing, BOXING, Gluing, counting

-

Packaging Type:

-

Cartons, Stand-up Pouch, Bags, Film, Foil, case

-

Packaging Material:

-

Plastic, Paper, Metal, Wood

-

Weight (KG):

-

400

-

Voltage:

-

380 V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhong Xin

-

Dimension(L*W*H):

-

2950*1260*2150 MM

-

Product name:

-

Powder bagging machine

-

Special:

-

Customization

-

Keyword:

-

Bagging machine

-

Color:

-

Customers' requirement

-

Advantage:

-

Easy operation

-

Speed:

-

180-300bags/hour or 360-480bag

-

Material:

-

Stainless steel

-

Suitable for:

-

Rice flour /corn starch/feed/wheaten starch

-

Pouch type:

-

Sack

-

Quality:

-

High quality

SIMILAR MACHINE

Granular packing machine

Powder packing machine

Ton bag packing machine

MACHINE SHOW

TECHNICAL PARAMETER

|

Model

|

DCS-F-50

|

|

Material

|

SUS304 Material contact part

|

|

Weighing range

|

5-50 Kg

|

|

Packing speed

|

180-300 bags/hour

|

|

Weighing error

|

+/- (0.1%-0.2%)

|

|

Power

|

4.5 Kw

|

|

Voltage

|

AC 220V/380V, 50HZ, 1P/3P or customized

|

|

Air Consumption

|

0.4-0.8 MPa

|

|

Applicable products

|

Powder products,such as: flour,starch,rubber adhesive,water conditioner,sulfur powder,calcium powder,zinc powder,iron powder,bean powder,sugar powder,milk powder,etc.

|

A

PPLIC

ABLE MATERIAL

MACHINE FEATURES

•

The material contact part is made of 304 stainless steel, more durable

• High-precision controller, automatic error correction, alarm for over and under tolerance

• Adopt imported control instrument, sensor and pneumatic elements.

• High speed feeding,weighing,sealing and greatly improve the speed.

• Reserve dust removal interface

• High-precision controller, automatic error correction, alarm for over and under tolerance

• Adopt imported control instrument, sensor and pneumatic elements.

• High speed feeding,weighing,sealing and greatly improve the speed.

• Reserve dust removal interface

MACHINE DETAIL

Screw feeding device

•

Can single screw or double screws design

• Precise screw pitch design improves accuracy

• 304 stainless steel, more corrosion-resistant

• Precise screw pitch design improves accuracy

• 304 stainless steel, more corrosion-resistant

Sewing machine motor

•

Hard copper core motor, durable

•

Low energy consumption, saving resources

•

Corrosion resistant, resists erosion and oxidation

Control Cabinet Layout

•

Clear and tidy layout,easy to install

• Famous brand electrical components, Siemens electrical components are available

• Equipped with frequency converter to improve accuracy

• Famous brand electrical components, Siemens electrical components are available

• Equipped with frequency converter to improve accuracy

Discharge port

•

304 stainless steel, more durable

•

Adjustable clip belts are suitable for different size bags

•

The design of the oval discharge port prevents dust from flying out

COMPONENTS BRAND

OPTIONAL DEVICE

SUCCESSFUL PROJECT

COMPANY PROFILE

Shandong Zhongxin Automation Equipment Co., Ltd. is a new-type enterprise integrating R&D and sales of automated packing equipment, palletizer equipment, and automatic batching systems. The company has strong R&D and design capabilities and a complete R&D center, skilled in business and people-oriented. Its technical performance and degree of automation are in a leading position in the country, and the company has a variety of product certifications. It mainly produces and sells automatic equipment such as quantitative packing machine, ton bag packing machine, robot palletizer, high-position palletizer, automatic sewing system, automatic batching system, and fertilizer production line etc.

FOREIGN CUSTOMERS VISIT

CUSTOMER FEEDBACK

SHIPPING DISPLAY

•

Steel frame fixed then packed in wooden box to ship

•

15-20 days after receiving the deposit

•

One year warranty

FAQ

Q1:How could I choose the right packing machine?

A1:We have various item of packing machine to suit for pack different materials, just let me know your product and requirement, we will choose the suitable item and make a drawing for you to confirm. Also your customize design are available, we have more than 20 person engineers team and R&D team.

Q2: What is your terms of payment method?

A2: T/T, L/C, D/P, D/A, ALL TERMS.

Q3:How about your delivery time?

A3:Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4:Do you test all your machines before delivery?

A4:Yes, we have 100% test before delivery.

Q5:How do you make our business long-term and good relationship?

A5:1, We keep good quality and competitive price to ensure our customers benefit .

2, We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

3, We have a professional and responsible after-sales service system.

Q2: What is your terms of payment method?

A2: T/T, L/C, D/P, D/A, ALL TERMS.

Q3:How about your delivery time?

A3:Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4:Do you test all your machines before delivery?

A4:Yes, we have 100% test before delivery.

Q5:How do you make our business long-term and good relationship?

A5:1, We keep good quality and competitive price to ensure our customers benefit .

2, We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

3, We have a professional and responsible after-sales service system.

Hot Searches